Engineering plastics, preparation method and application for preparing surgical operating instrument

A technology for engineering plastics and surgery, applied in the field of engineering plastics, can solve the problem that polyamide cannot meet the dimensional stability of surgical instruments, and achieve the effects of high dimensional stability, excellent colorability, and good anticoagulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

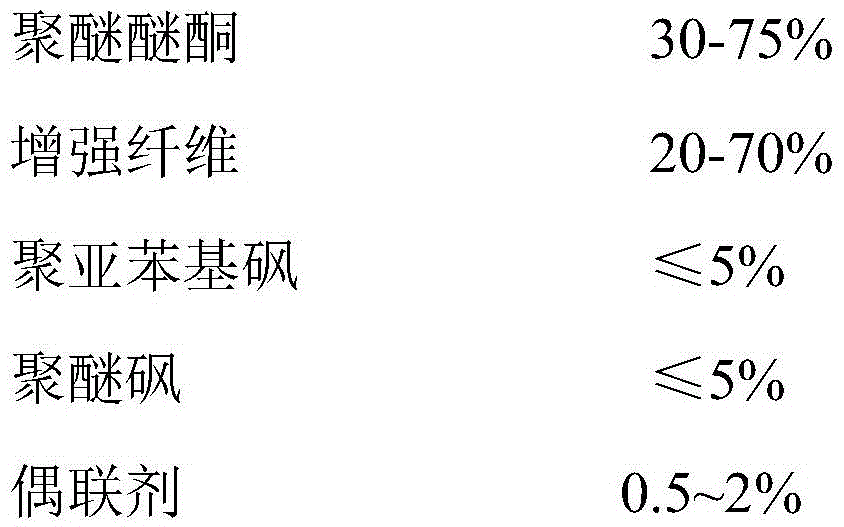

[0035] Preparation of the hemostat. formula:

[0036]

[0037] Described coupling agent is silane coupling agent A-1120;

[0038] The high temperature lubricant is polyorganosiloxane, and the antistatic agent is carbon black.

[0039] Preparation:

[0040] (1) The glass fiber is first oxidized with nitric acid, the specific steps are as follows:

[0041] Soak the glass fibers in concentrated nitric acid for 20 minutes to remove impurities on the surface of the fibers and increase the surface roughness, then wash them with deionized water until neutral, and dry them in a vacuum oven at 110°C for 2 hours.

[0042] (2) adding the treated glass fiber and coupling agent into a high mixer and mixing to obtain modified glass fiber;

[0043] (3) Dry polyether ether ketone, polyphenylene sulfone, and polyether sulfone at 110° C. for 3 hours;

[0044] (4) Add the dried polyether ether ketone, polyphenylene sulfone, polyether sulfone and additives into a high-speed mixer and mix ...

Embodiment 2

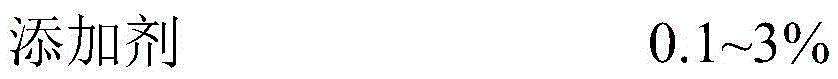

[0053] Surgical Scissors: Recipe:

[0054]

[0055] The coupling agent is silane coupling agent A-1120, the high-temperature lubricant is polyorganosiloxane, and the antioxidant is N,N'-bis-[3-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionyl] hexamethylenediamine (antioxidant 1098) and tris [2.4-di-tert-butylphenyl] phosphite (antioxidant 168), the mass ratio of the two is 1:1. Preparation:

[0056] (1) Carbon fiber is first oxidized with nitric acid, the specific steps are as follows:

[0057] Dip the carbon fiber in concentrated nitric acid for 20 minutes to remove impurities on the surface of the fiber and increase the surface roughness, then wash it with deionized water until neutral, and dry it in a vacuum oven at 120°C for 1 hour.

[0058] (2) adding the treated carbon fiber and coupling agent into a high mixer and mixing to obtain modified carbon fiber;

[0059] (3) Dry polyether ether ketone, polyphenylene sulfone and polyether sulfone at 180°C for 1 hour respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com