A method and equipment for continuous in-situ catalytic cracking of biomass raw materials for cogeneration of gas and carbon

A biomass raw material and in-situ catalysis technology, which is applied in the direction of biofuel, special carbonization, indirect heating carbonization, etc., can solve the problems of low gas active components, low quality of biomass charcoal, and low utilization efficiency of biomass energy. Achieve the effects of improving utilization efficiency, wide application, and improving effective gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 As shown, the continuous external heating biomass in-situ catalytic cracking gas and carbon co-production equipment includes moving bed reactor 2 and external combustion reactor 6 for biomass in-situ catalytic cracking, and the moving bed reactor is located outside In the combustion reactor, there is a silo 1 above one end of the moving bed reactor, a biomass pyrolysis gas outlet 4 above the other end, and a biomass charcoal and cracking catalyst outlet 5 below. There is a rotating lifting plate 3, and the rotating lifting plate continuously sends the mixture of biomass raw material and cracking catalyst fed through the silo into the middle of the moving bed reactor under the action of external force to carry out the pyrolysis and cracking reforming process of biomass charcoal. The external combustion reactor is provided with a fuel inlet 7 and an air chamber 9 for supplying fuel combustion aids, and the upper part of the external combustion reactor is ...

Embodiment 2

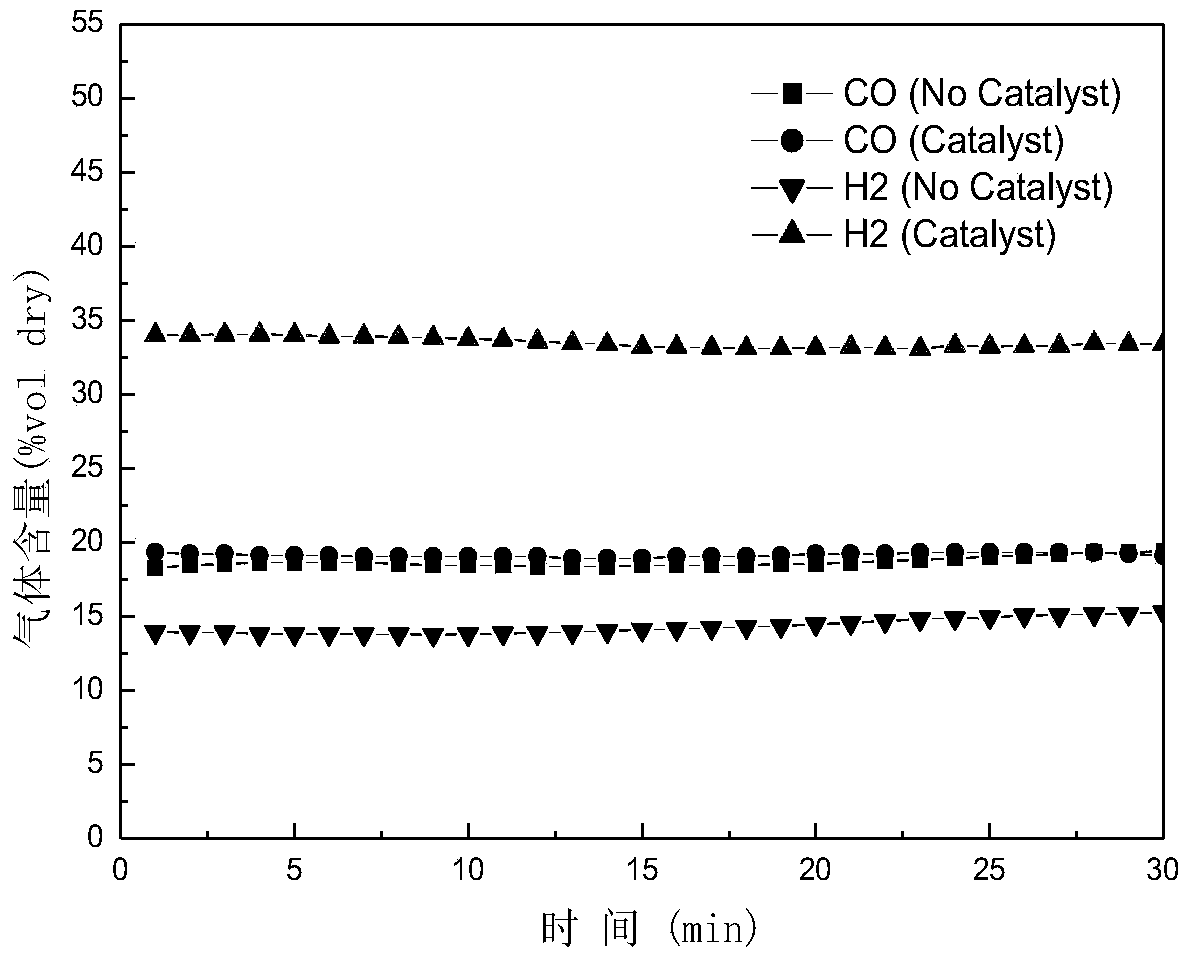

[0036] The chaff biomass raw material and the cracking reforming catalyst are mixed according to the mass ratio of 7.5:0.5, and then enter the mobile reactor 2 from the silo 1, and the biomass for complete combustion is sent from the entrance 7 of the external combustion reactor 6. into the external combustion reactor, complete combustion under the action of the air provided by the air chamber 9, while controlling the air-fuel ratio, the combustion reaction temperature is controlled within the temperature range of 650-800 °C, and the flue gas generated after combustion is discharged from the 8, due to The moving bed reactor is located in the external combustion reactor 6. Biomass fuel etc. are burned in the combustion reactor 6, and the heat generated by the combustion is supplied to the biomass in the moving bed reactor 2 through heat radiation, convection and heat conduction. The heat required for the pyrolysis of substances and the accompanying in-situ catalytic cracking of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com