Reactive distillation coupled novel process and device for separating liquid-phase products of ethylene glycol from coal

A coal-to-ethylene glycol and ethylene glycol technology is applied in the new separation process and device field of coal-to-ethylene glycol liquid-phase products, which can solve the problem of affecting the yield of ethylene glycol, high energy consumption of azeotropic rectification, and no Consider recycling and other issues to achieve the effect of reducing the reflux ratio and the total number of theoretical plates, reducing the reflux ratio and the theoretical number, and achieving remarkable energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

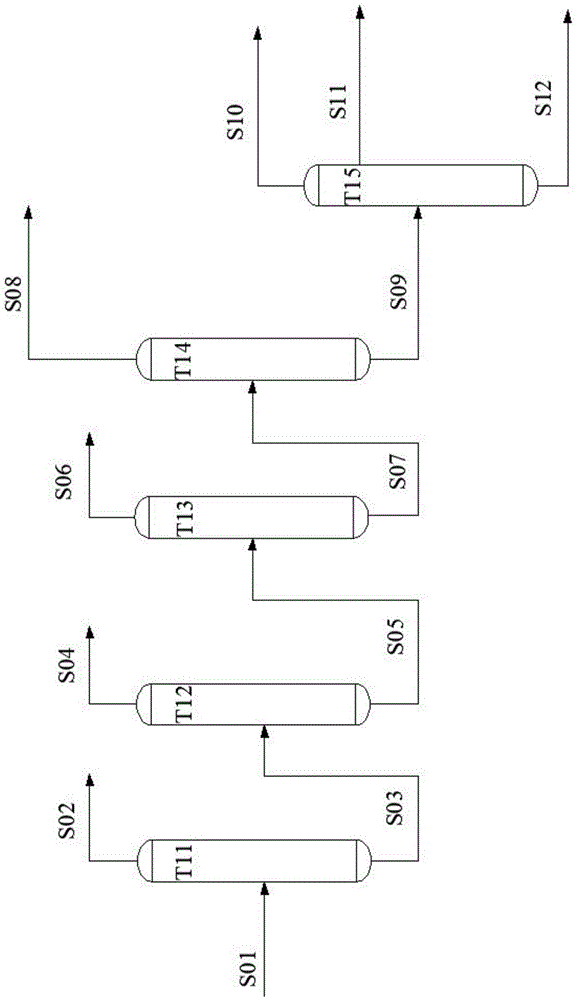

[0075] In this example, the mass composition of coal-based ethylene glycol liquid phase raw materials is: methanol 49.27%, ethylene glycol 45.20%, propylene glycol 0.12%, 1,2-butanediol 1.06%, and ethanol, propanol, oxalic acid di methyl ester, water, etc. The first demethanol tower operates under normal pressure, with 58 primary wheels, a reflux ratio of 1.86, and 80% methanol removal at the top of the tower; the operating pressure of the second demethanol tower is 45KPa in terms of absolute pressure, the total number of theoretical plates is 43, and the reflux ratio 1.66. The content of ethylene glycol after removing methanol is 88.61w%. The operating pressure of the dehydrogenation tower is 20KPa, the total number of theoretical plates is 35, and the reflux ratio is 1.16. The ethylene glycol stream obtained from the tower kettle contains 96.50w% ethylene glycol, 0.27w% propylene glycol, and 2.26w% 1,2-butanediol . The operating pressure of the propylene glycol and butane...

Embodiment 2

[0078] Same as implementation case 1, the butanediol acetal product in implementation case 1 is not hydrolyzed, as figure 2 Shown, butanediol acetal / ketone product enters butanediol acetal / ketone product refining tower after the liquid phase extraction stream S24 of butanediol acetal / ketone product separation tower tower tank, and the total theoretical plate number of butanediol acetal / ketone product refining tower is 9. The operating pressure is normal pressure, the feed is fed from the decanter on the top of the tower, the organic phase enters the tower, the water phase is discharged, the operating pressure of the decanter is normal pressure, the operating temperature is 65 ° C, and the butanediol acetal product is obtained from the tower kettle (4-Ethyl-2-methyl-1,3-dioxolane).

[0079] After the above changes, the product purity of the butanediol acetal product is 99.6%.

Embodiment 3

[0081] Same as Example 1, acetaldehyde is replaced by propionaldehyde, the process before the acetal / ketone reactive distillation is the same as in Example 1, and the process after the acetal / ketone reactive distillation is similar to Example 1.

[0082] The reflux ratio of the acetal / ketone reactive distillation column was changed to 0.18. The operating pressure of the aldehyde / ketone recovery tower is changed to normal pressure operation. The total number of theoretical plates of the ethylene glycol acetal product hydrolysis tower is changed to 25, and the reflux ratio is changed to 0.8. The total number of theoretical plates in the hydrolysis tower of the butanediol acetal product is changed to 26, and the reflux ratio is changed to 0.8.

[0083] Through the above process, the purity of ethylene glycol reaches more than 99.92w%, the purity of butanediol reaches 99.0w%, the recovery rate of ethylene glycol reaches 94%, and the yield of butanediol is 90.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com