Method for recycling PCB (printed circuit board) acidic etching solution under photocatalytic actions

A technology of photocatalysis and etching waste liquid, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as high investment requirements for sewage treatment equipment, complex wastewater quality, and environmental pollution, and achieve Significant economic value and social and environmental benefits, broad promotion prospects, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Composite materials of photocatalyst / non-metallic conductor (reduced graphene oxide RGO / C 3 N 4 Composite) was prepared as follows:

[0035] (1) Carbon nitride (C 3 N 4 ) preparation: melamine is calcined and then ground to obtain carbon nitride (C 3 N 4 ) light yellow powder, the calcination temperature is 550°C, and the calcination time is 4h.

[0036] (2) Preparation of GO:

[0037] (a) Dissolve 2.5g of graphite powder and 1.25g of sodium nitrate in 60ml of concentrated sulfuric acid with a mass concentration of 95%, and place it in an ice bath for 30min.

[0038] (b) Add 7.5g of potassium permanganate and stir at room temperature for 12 hours.

[0039] (c) Add 75ml of deionized water, stir at high temperature, the temperature is 90°C, and the stirring time is 24h.

[0040] (d) adding 25 ml of hydrogen peroxide solution with a mass concentration of 30% while stirring to obtain a mixture.

[0041] (e) The mixture was centrifuged, and the product was washed with...

Embodiment 2

[0056] Photocatalyst / non-metallic conductor composites (g-C 3 N 4 -TiO 2 Composite materials) are prepared as follows:

[0057] 1. Carbon nitride (C 3 N 4 ) preparation: melamine is calcined and then ground to obtain carbon nitride (C 3 N 4 ) light yellow powder, the calcination temperature is 450°C, and the calcination time is 4h.

[0058] 2. Weigh 1.0gC 3 N 4 powder and 1.0g TiO 2 Powder, mix and grind the two in an agate mortar, then put the mixture into a hydrothermal reaction kettle, seal it and react in a muffle furnace at 550°C for 4h (heating rate is 2.0°C / min); get g-C 3 N 4 -TiO 2 composite material.

[0059] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

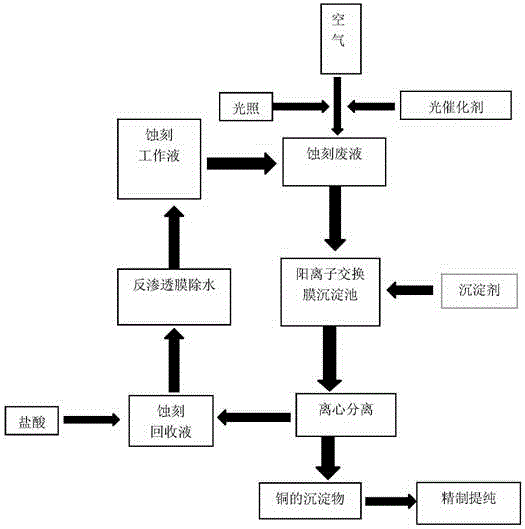

[0060] like figure 1 As shown, the technical scheme adopted in the recovery method of copper in the circuit board etching waste liquid of the present invention comprises the following steps:

[0061] 1. The acid etching solution is take...

Embodiment 3

[0069] Composite material of photocatalyst / non-metallic conductor (mpg-C 3 N 4 / RGO composites) were prepared as follows:

[0070] (1) Carbon nitride (C 3 N 4 ) preparation: melamine is calcined and then ground to obtain carbon nitride (C 3 N 4 ) light yellow powder, the calcination temperature is 450°C, and the calcination time is 4h.

[0071] (2) mpg-C 3 N 4 Preparation: 12gC 3 N 4 The powder was dissolved in 30 g of a 40% silica sol aqueous solution, and the mixture was evaporated to dryness. The obtained white powder was put into a combustion boat, and then sent into a tube furnace. Under the protection of 300mL / min nitrogen, the temperature was raised to 550°C at 2.3°C / min, maintained at this temperature for 4h, and cooled to room temperature naturally. A brownish-yellow powder was obtained, which was treated with 4mol / L ammonium bifluoride solution for 48h to remove the template agent. After the reaction, the solution was centrifuged to discard the supernatant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com