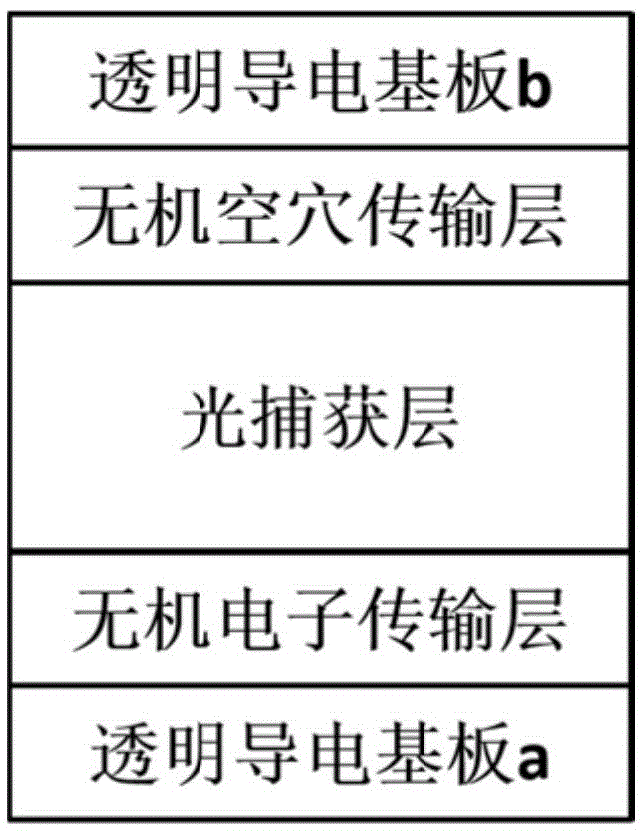

Semitransparent perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of high production cost, complex process, and low sunlight capture efficiency, and achieve the effects of improved stability, simple preparation process, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

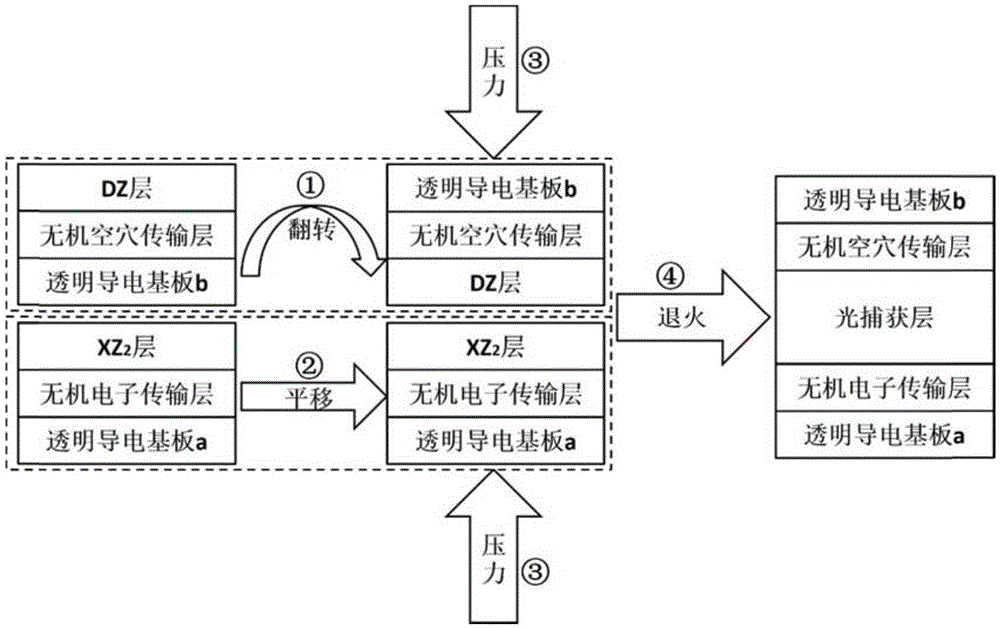

[0057] The first embodiment of the present invention provides a method for preparing a translucent perovskite solar cell, the specific steps of which are as follows:

[0058] a And substrate b or PET (PI) flexible transparent conductive film substrate a and substrate b.

[0059] (2) Spin-coat or scrape-coat TiO on the clean substrate a surface of step (1) 2 The precursor solution is annealed in a glove box at 80-120°C for 20-50 minutes, and prepared at low temperature, which has the advantage of being flexible and can be prepared in a large area.

[0060] Or heat the clean FTO transparent conductive glass substrate a at 400-600°C, spray the pre-prepared isopropyl titanate solution on the substrate, heat for 20-60 minutes, and finally obtain a surface coating with a thickness of 20-150nm TiO 2 The substrate a of the electron transport thin film is prepared by high temperature, which has the advantage of being simple and making the required conditions easier to achieve.

[0...

Embodiment

[0091] Example Table 1

[0092]

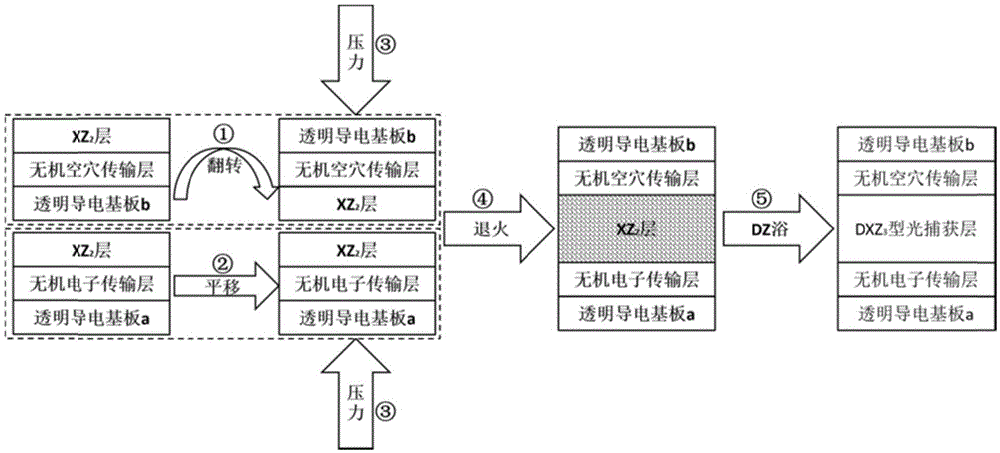

[0093] Ditto, such as image 3 The specific preparation steps shown are as follows:

[0094] Step (1) Substrate preparation: The FTO transparent conductive glass is ultrasonically cleaned with deionized water, ethanol and acetone in sequence, and then treated with ultraviolet and ozone for 20 minutes, and set aside.

[0095] Step (2) TiO 2 Preparation of the electron transport layer: pre-prepared isopropyl titanate ethanol solution at a ratio of 1:50, preheated the clean FTO transparent conductive glass substrate obtained in step (1) at 500°C, and then prepared the pre-prepared The ethanol solution of isopropyl titanate was sprayed on the substrate, and heated for 40 minutes to finally achieve the deposition of dense TiO with a thickness of 90nm. 2 Electron transport layer, cooled for later use.

[0096] Step (3) Preparation of NiO hole transport layer: Pre-prepared nickel acetylacetonate acetonitrile solution at a ratio of 1:50, prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com