Growth method of germanium-doped SiC body single-crystal material

A single crystal material and growth method technology, which is applied in the growth of polycrystalline materials, single crystal growth, single crystal growth, etc., can solve the problem of the inability to obtain germanium-doped SiC bulk single crystal materials, the limited implantation depth of ion implantation, and the inability to obtain thick It can reduce the defects and internal stress, reduce the stress, and reduce the single crystal defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for growing a germanium-doped SiC bulk single crystal material, the growth steps are as follows:

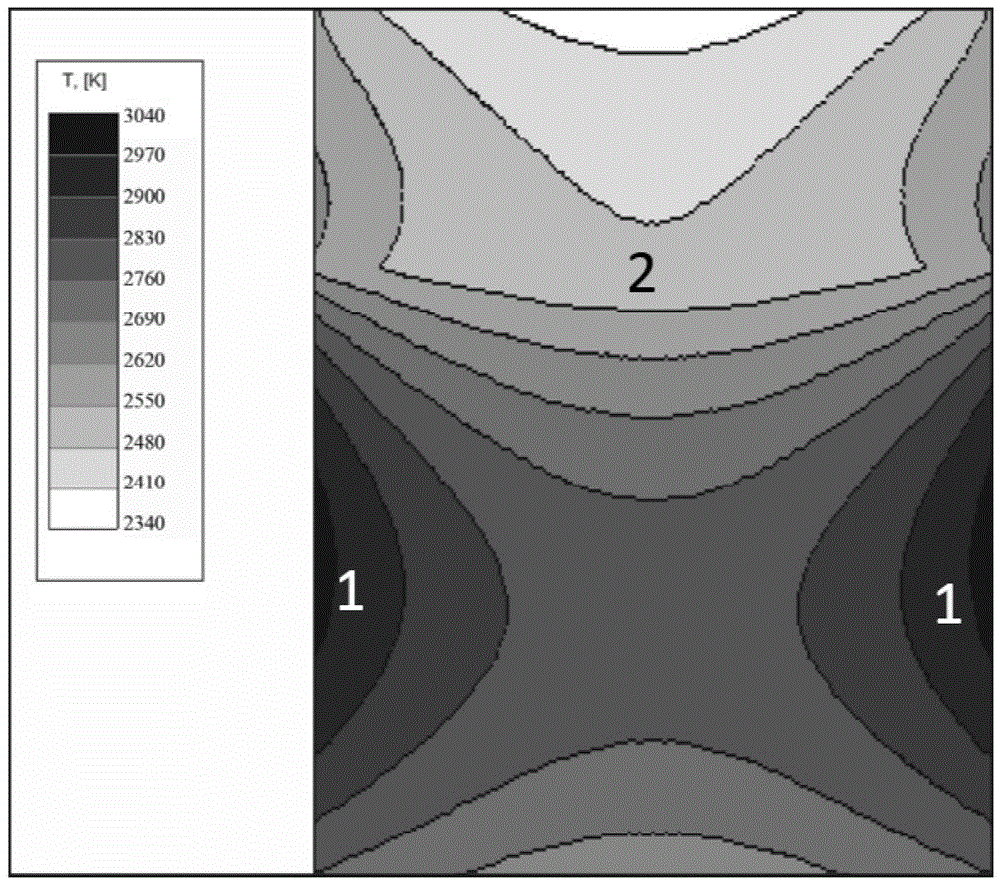

[0048](1) Adjust the relative position of the graphite crucible and the induction coil so that the bottom of the graphite crucible is at the center of the induction coil, so that the top of the graphite crucible obtains a flat temperature field;

[0049] (2) Place the SiC powder source in the graphite crucible, fix the 2-inch 4H-SiC seed crystal on the top of the graphite crucible, cover the crucible lid and place it in the growth chamber of the single crystal growth furnace, and use low vacuum conditions to remove water and oxygen and other harmful impurities.

[0050] (3) Vacuumize the growth chamber of the single crystal growth furnace to make the vacuum degree reach 10 -5 Pa, the growth chamber is heated by induction heating for crystal growth, and the temperature of the top of the growth chamber is measured at the same time, and the temperature of the top is...

Embodiment 2

[0056] A kind of growth method of germanium-doped SiC bulk single crystal material, with embodiment 1, difference is:

[0057] In step (2), the seed crystal used is a 2-inch 6H-SiC seed crystal, so the grown crystal is a 2-inch 6H-SiC single crystal;

[0058] In step (3), the vacuum degree of the growth chamber is 10 -2 Pa, the top temperature is controlled at 2200°C, the axial temperature gradient is controlled at 30°C / cm, the growth pressure is 70mbar, the nucleation rate is 100μm / h, the crystal growth time is 80h, and the argon flow rate is 30sccm.

[0059] In step (5), the total amount of pure metal germanium powder is 10% of the weight of the SiC powder source, and the mass ratio of the dopant in the high temperature zone and the low temperature zone is 5:1.

[0060] In step (6), the cooling rate is controlled at 0.5°C / min.

[0061] The germanium-doped SiC single crystal grown in this embodiment has no defects such as germanium drop voids, small internal stress in the c...

Embodiment 3

[0063] A kind of growth method of germanium-doped SiC bulk single crystal material, with embodiment 1, difference is:

[0064] In step (2), the seed crystal used is a 3-inch 4H-SiC seed crystal, so the grown crystal is a 3-inch 4H-SiC single crystal;

[0065] In step (3), the vacuum degree of the growth chamber is 10 -3 Pa, the top temperature is controlled at 2000°C, the axial temperature gradient is controlled at 10°C / cm, the growth pressure is 50mbar, the nucleation rate is 50μm / h, the crystal growth time is 60h, and the argon flow rate is 20sccm.

[0066] In step (5), the total amount of pure metal germanium powder is 0.5% by weight of the SiC powder source, and the mass ratio of the dopant in the high temperature zone and the low temperature zone is 2:1.

[0067] In step (6), the cooling rate is controlled at 0.4°C / min.

[0068] The germanium-doped SiC single crystal grown in this embodiment has no defects such as germanium drop voids, small internal stress in the cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com