Preparation and application of nitrogen-doped graphene-carbon nanohorn composites

A nitrogen-doped graphene and carbon nanohorn technology, which is applied in the preparation/purification of carbon, graphite, hybrid capacitor electrodes, etc., can solve the problems of graphene nanosheets being easy to reunite and electrochemical performance, and achieve high yield, The effect of expanding the application field and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

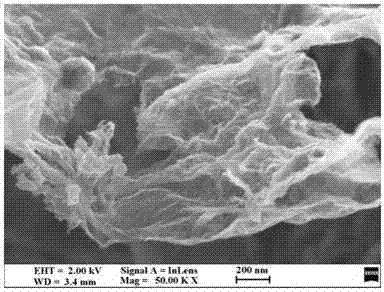

[0040] Preparation of graphene oxide: Take 1.0 g of expandable graphite and put it into a round bottom flask, then add 6.0 g of potassium permanganate, then add 120 mL of concentrated sulfuric acid and 14 mL of concentrated phosphoric acid into the round bottom flask in turn; Heat the oil bath to 50 °C, put the rotor into the flask, install the condenser on the flask, and put it into the oil bath for 24 hours of magnetic stirring; take it out from the oil bath; Ice bath in a beaker, add 30 wt% hydrogen peroxide dropwise and stir until all the reactants turn golden yellow; after cooling to room temperature, wash with deionized water, suction filter and centrifuge repeatedly until the solution is neutral; pour the solution In the evaporating dish, put it into a drying oven for drying; after drying, grind it to obtain graphene oxide, and bottle it for later use;

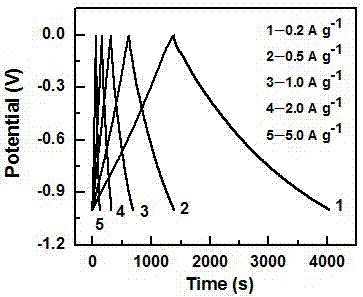

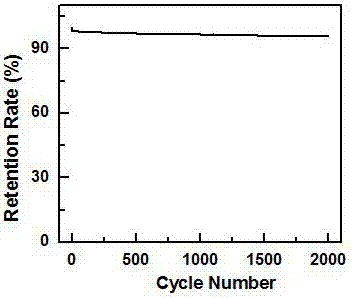

[0041] (1) Dissolve 200 mg of graphene oxide powder in deionized water to prepare a dispersion with a concentration o...

Embodiment 2

[0045] The preparation of graphene oxide is the same as in Example 1.

[0046] (1) Dissolve 200 mg of graphene oxide powder in deionized water to prepare a dispersion with a concentration of 5.58 mg / mL, add 30 mg of sodium lignosulfonate after ultrasonic dispersion for 30 min, and add 20 g of melamine after ultrasonic dispersion for 30 min As a nitrogen dopant, add 5 mg carbon nanohorns to obtain a mixture of graphene oxide-lignosulfonic acid-melamine-carbon nanohorns; add deionized water to 100 mL, sonicate for 1 h, and pour it into an evaporating dish , dried in an oven at 60 °C to obtain a black solid powder, and then ground to obtain a precursor;

[0047] (2) Put the dried black precursor solid powder in (1) in a crucible, and carry out pyrolysis at 800 °C under the protection of 100 mL / min inert gas; heat up to 800 ℃, heat preservation for 120 min, and then cool with the furnace to obtain nitrogen-doped graphene-carbon nanohorn composite material, grind the sample and st...

Embodiment 3

[0050] The preparation of graphene oxide is the same as in Example 1.

[0051] (1) Dissolve 200 mg of graphene oxide powder in deionized water to prepare a dispersion with a concentration of 5.58 mg / mL, add 20 mg of cellulose sodium after ultrasonic dispersion for 30 min, and add 20 g of urea as nitrogen after ultrasonic dispersion for 30 min Dopant, then add 5 mg carbon nanohorn to obtain graphene oxide-cellulose sodium-urea-carbon nanohorn mixture; then add deionized water to 100 mL, after ultrasonication for 1 h, pour it into an evaporating dish, at 60 ℃ oven drying to obtain a black solid powder, and then grind to obtain a precursor;

[0052] (2) Put the dried black precursor solid powder in (1) in a crucible, and carry out pyrolysis at 700 °C under the protection of 200 mL / min inert gas; heat up to 700 ℃, heat preservation for 120 minutes, and then cool with the furnace to obtain nitrogen-doped graphene-carbon nanohorn composite materials, grind the samples and label the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com