Martensite-ferrite double-phase wear-resisting steel plate and preparing method thereof

A wear-resistant steel plate and martensite technology, which is applied in the field of martensite-ferrite dual-phase wear-resistant steel plate and its preparation, can solve the problem that the hardness, low temperature toughness and wear resistance are difficult to meet the actual use requirements, and the impact toughness is difficult to guarantee. , poor toughness and plasticity, etc., to achieve the effect of improving rigidity, good strength and toughness coordination, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

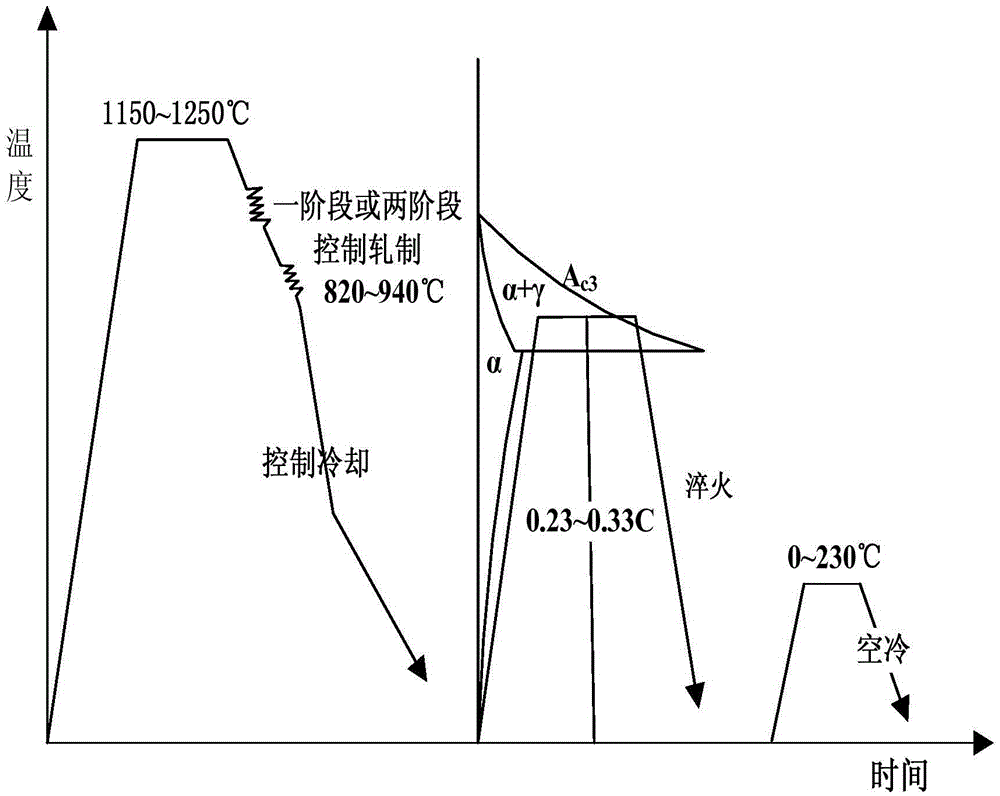

Method used

Image

Examples

Embodiment 1

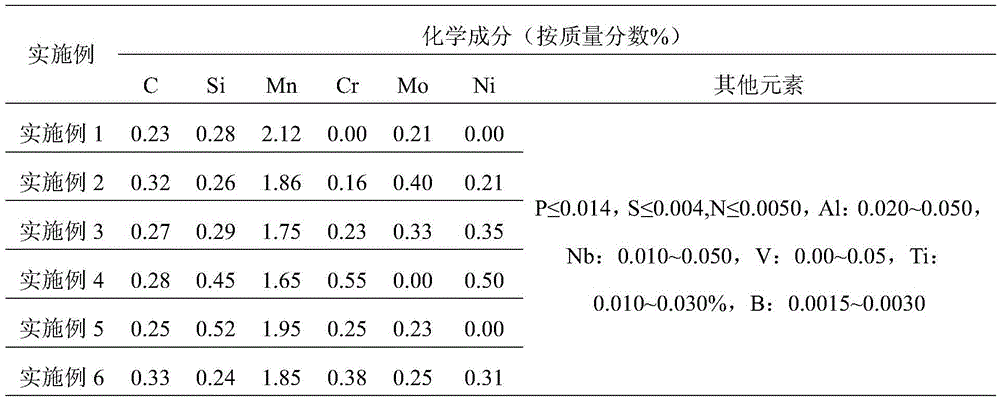

[0059] The chemical composition of embodiment 1 is as shown in table 1. Carry out electric furnace or converter smelting according to the chemical composition of Example 1 in Table 1, pour into continuous casting slabs or steel ingots after refining, heat the continuous casting slabs or steel ingots to 1200 ° C, keep warm for 3 hours, and then carry out controlled rolling and controlled cooling process, in which the finishing rolling temperature of rough rolling is 1040°C, and the pass reduction rate is not less than 15%; the starting temperature of finishing rolling is 880°C, the finishing rolling temperature is 840°C, and the rolling thickness of the steel plate is 20mm; the steel plate is controlled after rolling Cooling, the final cooling temperature is 640°C, and then air-cooled to room temperature; finally, the steel plate is heat treated, wherein the quenching temperature is 810°C, the holding time is 10min, the tempering temperature is 210°C, and the tempering time is 6...

Embodiment 2

[0062] The chemical composition of embodiment 2 is as shown in table 1. Carry out electric furnace or converter smelting according to the chemical composition of Example 2 in Table 1, pour into continuous casting slab or steel ingot after refining, heat continuous casting slab or steel ingot to 1220 ℃, keep warm for 3.5 hours, then carry out controlled rolling and controlled cooling process, in which the finishing rolling temperature of rough rolling is 1050°C, and the pass reduction rate is not less than 15%; the starting temperature of finishing rolling is 880°C, the finishing rolling temperature is 830°C, and the rolling thickness of the steel plate is 30mm; the steel plate is controlled after rolling Cooling, the final cooling temperature is 620°C, and then air-cooled to room temperature; finally, the steel plate is heat treated, wherein the quenching temperature is 795°C, the holding time is 15min, the tempering temperature is 190°C, and the tempering time is 100min.

[0...

Embodiment 3

[0065] The chemical composition of embodiment 3 is as shown in table 1. Carry out smelting in electric furnace or converter according to the chemical composition of Example 3 in Table 1, pour into continuous casting slab or steel ingot after refining, heat the continuous casting slab or steel ingot to 1180 ℃, keep warm for three hours, then carry out controlled rolling and controlled cooling process, wherein the finishing rolling temperature of rough rolling is 1030°C, and the pass reduction rate is not less than 15%; the starting temperature of finishing rolling is 880°C, the finishing rolling temperature is 825°C, and the rolling thickness of the steel plate is 12mm; the rolled steel plate is air-cooled to Room temperature; finally, the steel plate is subjected to heat treatment, wherein the quenching temperature is 805°C, the holding time is 15min, the tempering temperature is 190°C, and the tempering time is 35min.

[0066] In the structure obtained in this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com