Preparation method of spherical porous lithium-ion battery high-voltage cathode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reversible capacity not meeting the target requirements, fast capacity decay, poor rate performance, etc., and achieve considerable reversible capacity and uniform particle size Consistent, improved energy density and power density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

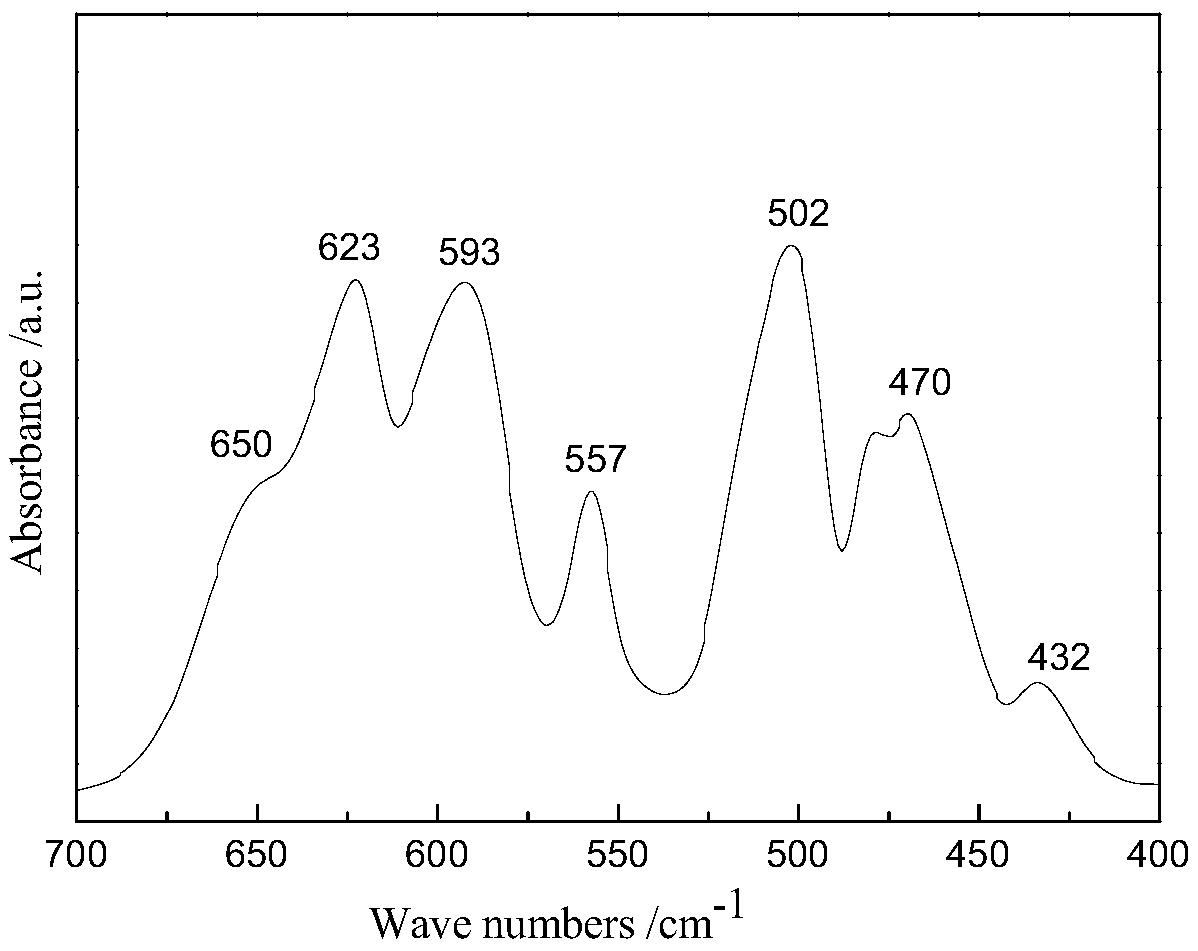

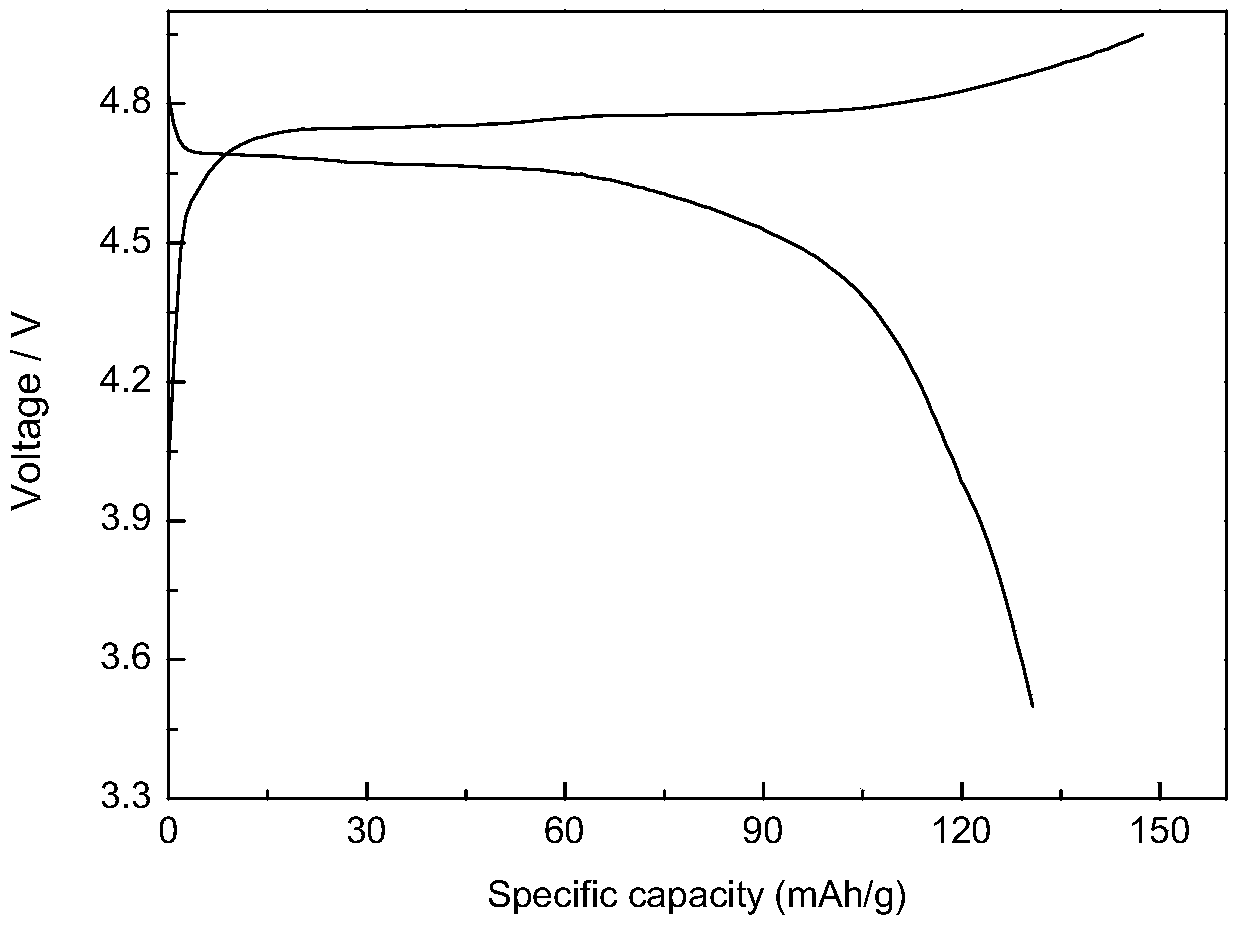

Embodiment 1

[0027] Dissolve 0.05 mol of nickel sulfate and 0.15 mol of manganese sulfate in a mixed solution of 50 mL of distilled water and ethanol (the volume ratio of distilled water to ethanol is 2:1), then add 0.31 mol of ammonium bicarbonate, stir at room temperature for 30 minutes, and then dissolve the obtained The mixture was put into a 200mL hydrothermal kettle to react at 210°C for 11h, and then the precipitate was filtered out, washed and dried to obtain a carbonate compound precursor. The obtained carbonic acid compound precursor and 0.0505 mol of lithium carbonate ball mill were mixed evenly, and then placed in a muffle furnace for 6 h at 500 ° C, and then 800 ° C for 12 h, and then kept at 600 ° C for 8 h, that is, the porous spherical shape with P4 3 32-structure high-voltage lithium-ion battery cathode material LiNi0.5 mn 1.5 o 4 . 0.0018molLiNO 3 , 0.00306molLa (NO 3 ) 3 ·6H 2 O, 0.00547molTi(C 4 h 9 O) 4 (Tetrabutyl titanate) was dissolved in 20 mL of ethanol, ...

Embodiment 2

[0029] Dissolve 0.05 mol of nickel sulfate and 0.15 mol of manganese sulfate in a mixed solution of 50 mL of distilled water and acetone (the volume ratio of distilled water to acetone is 2:1), then add 0.31 mol of ammonium bicarbonate, stir at room temperature for 30 minutes, and then dissolve the obtained The mixture was put into a 200mL hydrothermal kettle to react at 220°C for 12h, and then the precipitate was filtered out, washed and dried to obtain a carbonate compound precursor. Mix the obtained carbonic acid compound precursor and 0.11mol lithium hydroxide ball mill evenly, put it in a muffle furnace and bake it at 500°C for 6h, and then bake it at 800°C for 15h, and then keep it at 600°C for 5h, that is, the porous spherical shape with P4 3 32-structure high-voltage lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 . With 0.0018mol lithium acetate, 0.00306mol lanthanum acetate, 0.00547molTi(C 4 h 9 O) 4 (Tetrabutyl titanate) was dissolved in 20 mL of etha...

Embodiment 3

[0031] Dissolve 0.05 mol of nickel sulfate and 0.15 mol of manganese sulfate in a mixed solution of 50 mL of distilled water and benzyl alcohol (the volume ratio of distilled water to benzyl alcohol is 2:1), then add 0.35 mol of ammonium bicarbonate, stir at room temperature for 30 minutes, and then The resulting mixture was added to a 200 mL hydrothermal kettle to react at 220° C. for 6 h, and then the precipitate was filtered out, washed and dried to obtain a carbonate compound precursor. Mix the obtained carbonic acid compound precursor and 0.11mol lithium acetate ball mill evenly, put it in a muffle furnace and bake it at 600°C for 6h, then bake it at 800°C for 15h, and then keep it at 600°C for 5h, that is, the porous spherical shape with P4 3 32-structure high-voltage lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 . Dissolve 0.0018 mol of lithium acetate, 0.00306 mol of lanthanum acetate, and 0.00547 mol of tetrapropyl titanate in 20 mL of ethanol, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com