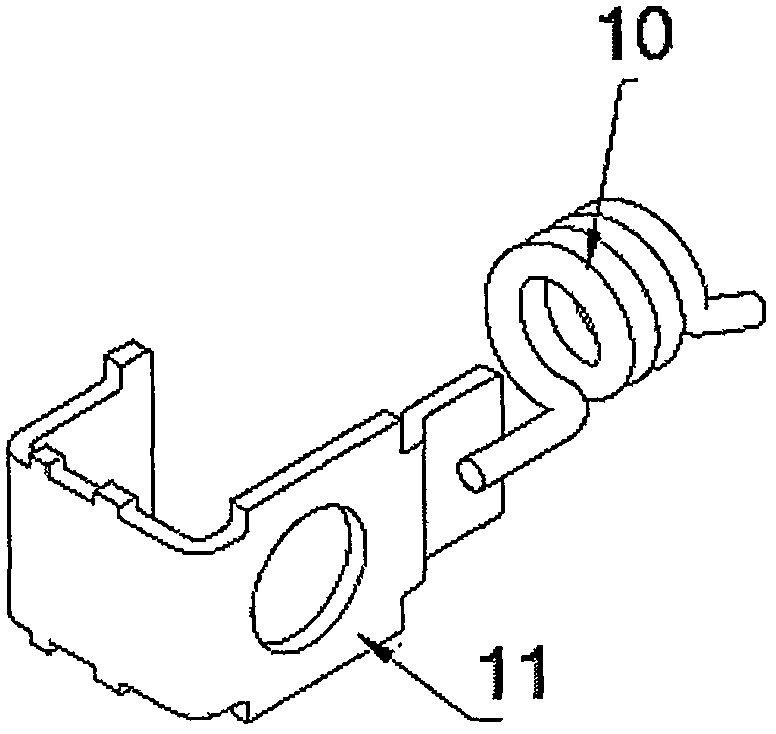

Copper-aluminum composite material, coil assembly of miniature circuit breaker and preparation method thereof

A technology of small circuit breakers and composite materials, which is applied in the manufacture of circuits, electrical components, and emergency protective devices. Light weight, lower overall cost, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The first step is to slot the copper or copper alloy strip

[0060] The parameters are as follows: the number of grooves is 1 or more, the groove width is 2mm-25mm, the depth is 0.2mm-10mm, and the distance between any two grooves is greater than 20mm; the width of copper or copper alloy strips is between 30mm-150mm The thickness is between 1mm and 20mm.

[0061] The second step is to clean the grooved copper or copper alloy strip and aluminum or aluminum alloy strip obtained in the first step

[0062] The parameters used are: aluminum or aluminum alloy material strip width H (size), groove width -0.5mm≤H≤groove width+0.5mm, aluminum or aluminum alloy strip thickness is the same as groove depth; cleaning speed is 0.1m / min~ 10m / min, use one time of cleaning or multiple times of cleaning until the surface of the strip is a new rough surface.

[0063] The third step is to mosaic composite the strip after cleaning

[0064] Wherein: thickness after compounding / thickness b...

Embodiment 2

[0082] Taking the copper-aluminum composite material of the coil and its connecting plate prepared by preparing multiple round aluminum wires as an example

[0083] The first step is to slot the copper strip; among them: the number of slots is 1, the slot width is 25mm, and the slot depth is 2mm; the width of the copper strip is 150mm, the thickness is 20mm, and the slot is located at the center of the copper strip;

[0084] The second step is to clean the grooved copper and aluminum strips obtained in the first step; among them: the aluminum width is 24.5mm, the thickness is 2mm; the cleaning speed is 0.1m / min, and the cleaning time is 1 time. The surface of the belt is a new rough surface;

[0085] The third step is to carry out cold compounding of the tape after cleaning, and the thickness of the tape after compounding is 4mm;

[0086] The fourth step is to carry out continuous annealing of the compound strip, wherein: the effective temperature zone of the annealing furnac...

Embodiment 3

[0095] Take the copper-aluminum composite material for preparing a coil and its connecting plate from a single round wire as an example:

[0096] The first step is to slot the copper alloy strip; among them: the number of slots is 3, the slot width is 2mm, and the slot depth is 0.2mm; the width of the copper strip is 150mm, the thickness is 1mm, and the distance between any two slots is 40mm;

[0097] The second step is to clean the grooved copper alloy strip and aluminum alloy strip obtained in the first step; among them: the width of the aluminum strip is 2.5mm, the thickness is 0.2mm; the cleaning speed is 10m / min, twice Cleaning, the surface of the strip is a new rough surface;

[0098] The third step is to carry out thermal compounding on the tape after cleaning, and the thickness of the tape after compounding is 0.8mm;

[0099] The fourth step is to perform solid-phase annealing on the compound strip, wherein: the temperature is 200°C, the time is 8h, and the atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com