Preparation method of cellulose-based flexible stress-strain sensitive material

A technology of sensitive materials and cellulose, applied in the direction of measuring force, instruments, measuring devices, etc., can solve problems such as high cost, environmental pollution, resource shortage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ① Add 10 g of pulp cellulose to 1000 g of water, and stir for 1 hour with a mixer to form a uniform solution to obtain a 1 wt % pulp cellulose aqueous solution.

[0026] ② The pulp cellulose aqueous solution prepared in step ① is frozen into a solid, and then dried by a freeze dryer to obtain the cellulose airgel.

[0027] ③ The cellulose airgel prepared in step ② was cracked under nitrogen protection at 800° C. for 2 hours to obtain a cellulose-based carbon gel material.

[0028] ④The carbon gel material prepared in step ③ was poured with 1.2 times the volume of PDMS resin, vacuum degassed, and then cured at 80°C for 1 hour to obtain a flexible stress-strain sensitive material based on cellulose.

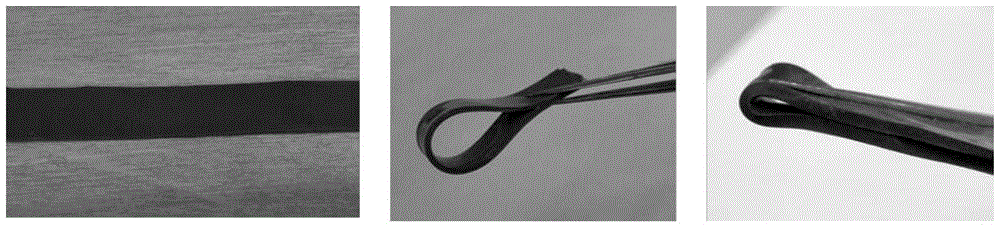

[0029] The scanning electron microscope (TEM) photos of the prepared cellulose carbon sol are as follows: figure 2 As can be seen from the figure: the cellulose carbon sol prepared by the present invention has a large number of voids, a large number of contact points betwe...

Embodiment 2

[0031] ① Add 2 g of cellulose nanocrystals to 1000 g of water, and use an ultrasonic instrument to sonicate for 30 minutes to form a uniform solution to obtain a 0.2 wt % aqueous solution of cellulose nanocrystals.

[0032] ② The cellulose nanocrystal aqueous solution prepared in step ① is frozen into a solid, and then dried by a freeze dryer to obtain the cellulose aerogel.

[0033] ③ The cellulose airgel prepared in step ② was cracked under the protection of argon at 1000° C. for 0.5 hour to obtain a cellulose-based carbon gel material.

[0034] ④Pouring polymethylsiloxane resin (Sylgard184, DowCorning) with 1 times its volume on the carbon gel material prepared in step ③, vacuum defoaming, and then curing at 80°C for 1h, the cellulose-based flexible stress - Strain sensitive materials.

[0035] The cellulose carbon sol prepared by using the method provided by the invention has a three-dimensional network structure, and the conductivity is 0.82Sm -1 . The prepared stress-...

Embodiment 3

[0037] ①Add 50g of chitin cellulose to 1000g of water, and stir for 5 hours with a mixer to form a homogeneous solution to obtain a 5wt% chitin cellulose aqueous solution.

[0038] ② The chitin cellulose aqueous solution prepared in step ① is frozen to become solid, and then dried by a freeze dryer to obtain the cellulose airgel.

[0039] ③ The cellulose airgel prepared in step ② was cracked under vacuum at 600° C. for 5 hours to obtain a cellulose-based carbon gel material.

[0040] ④The carbon gel material prepared in step ③ was poured with PDMS resin twice its volume, vacuum degassed, and then cured at 80°C for 1 hour to obtain a flexible stress-strain sensitive material based on cellulose.

[0041] The cellulose carbon sol prepared by the method provided by the invention has a three-dimensional network structure, and the conductivity is 0.0012Sm -1 . The prepared stress-strain sensitive material has good flexibility, and the electrical resistance of the material is sensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com