Method for continuously removing chlorine and nitrate in extracting solution of tobacco

A technology for tobacco extraction and extraction liquid, applied in the field of chlorine and nitrate, can solve the problems of loss of effective components of cigarettes, low removal efficiency, chemical residues, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

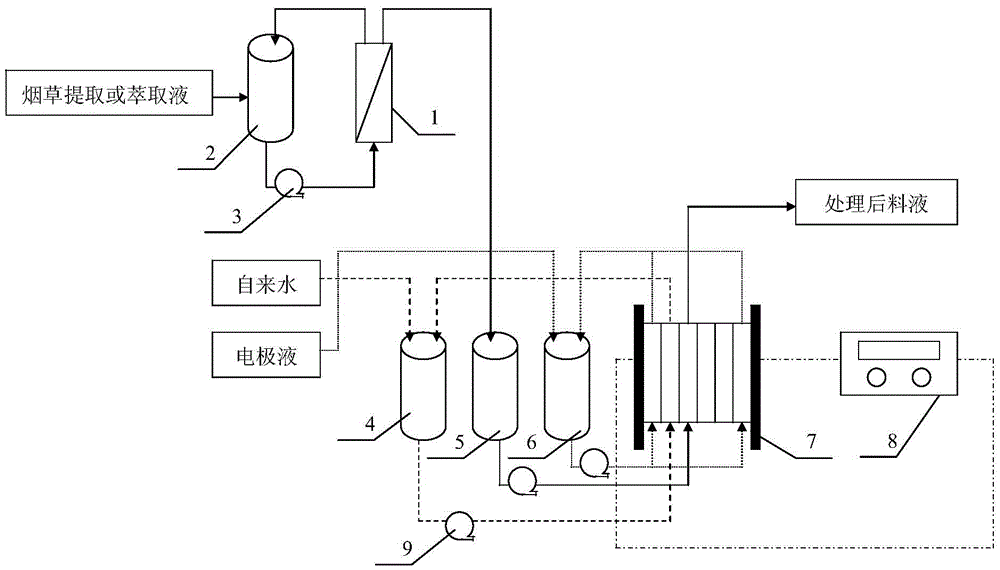

[0024] In this embodiment, the method for continuously removing chlorine and nitrate in tobacco extraction or extract liquid is carried out by using a combination of ceramic membrane device and electrodialysis device.

[0025] Such as figure 1 As shown, the ceramic membrane device includes a ceramic membrane module 1, a feed liquid tank 2 and a ceramic membrane device circulation pump 3; The liquid inlet is connected, the liquid outlet of the circulation pump 3 of the ceramic membrane device is connected with the ceramic membrane module 1 through the pipe; Used to output dialysate;

[0026] Such as figure 1 As shown, the electrodialysis device is composed of a desalination chamber material tank 5, a concentration chamber material tank 4, an electrode chamber material tank 6, an electrodialysis membrane assembly 7, three electrodialysis device circulation pumps 9, a DC power supply 8 and pipelines; the electrodialysis membrane The component is composed of an anode, a cathode...

Embodiment 2

[0033] The present embodiment adopts the same device as in Example 1, and continuously removes chlorine and nitrates in the tobacco extraction or extraction liquid according to the following steps:

[0034] First, 15L of tobacco extract with a solid content of 16.84% (the chlorine content is about 1.05%, and the nitrate content is about 0.72%) is introduced into the feed liquid tank of the ceramic membrane device for circulating filtration, and the operating temperature is controlled to be ≤35°C. Pressure≤0.5MPa;

[0035] Then the obtained dialysate is continuously output from the dialysis outlet to the material tank of the desalination chamber of the electrodialysis device, and 15L of tap water is added to the material tank of the concentration chamber, and 10L of electrode solution is added to the material tank of the electrode chamber; the dialysis is controlled by a circulating pump The liquid circulates between the desalination chamber and the material tank of the desalin...

Embodiment 3

[0039] The present embodiment adopts the same device as in Example 1, and continuously removes chlorine and nitrates in the tobacco extraction or extraction liquid according to the following steps:

[0040] First, 15L of tobacco extract with a solid content of 12.45% (its chlorine content is about 0.82%, and its nitrate content is about 0.58%) is introduced into the feed liquid tank of the ceramic membrane device for circulating filtration, and the operating temperature is controlled to be ≤35°C. Pressure ≤ 0.5MPa; then the obtained dialysate is continuously output from the dialysate outlet to the material tank of the desalination chamber of the electrodialysis device, and 15L of tap water is added to the material tank of the concentration chamber, and 10L of electrode solution is added to the material tank of the electrode chamber; The circulation pump controls the circulation of the dialysate between the desalination chamber and the material tank of the desalination chamber, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com