Device and method for laser cleaning composite coating

A laser cleaning and composite coating technology, which is applied in the field of metal surface cleaning, can solve problems that do not involve the layered removal method of composite coatings, and achieve the effect of selective removal of coatings, easy operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention are given below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all belong to the protection scope of the present invention.

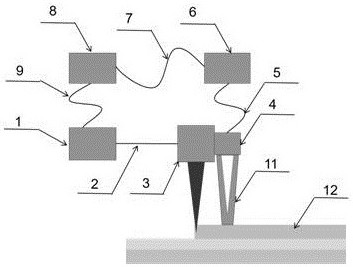

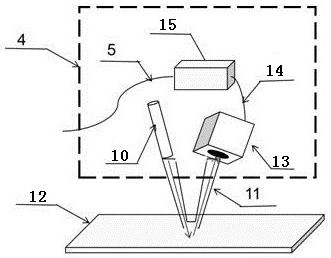

[0029] The laser cleaning composite coating device of the present invention comprises a cleaning head 3 for cleaning the coating. The present invention cleans by laser, so the cleaning head 3 is connected with a laser 1 through an energy-transmitting optical fiber 2, and the pulsed laser light emitted by the laser 1 is transmitted The energy fiber 2 is conducted to the cleaning head 3. Different from the prior art, the present invention fixedly connects a spectrum sensing device 4 to the other end of the cleaning head 3, usually through a fixed connection with the housing of the spectrum sensing device 4 through bolts, no special restri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com