Silicone rubber fire-proof high-voltage-resistant insulated wire and preparation method thereof

A technology of insulated wires and silicone rubber, applied in the field of wires, can solve the problems of unsatisfactory fire resistance performance and high voltage resistance performance of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

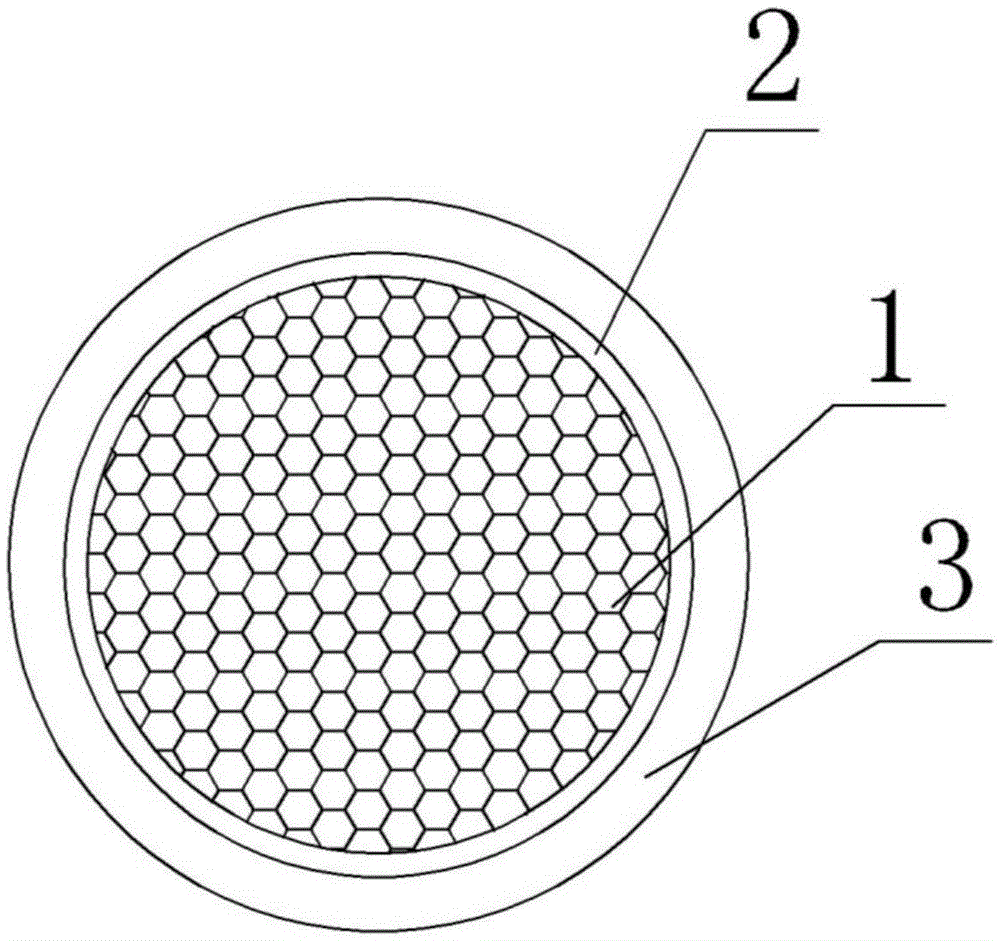

[0022] Such as figure 1 as shown, figure 1 It is a cross-sectional view of a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention.

[0023] refer to figure 1 , a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention, comprising a conductor 1 and an insulating layer 3 coated on the outer periphery of the conductor 1, a coating 2 is coated between the conductor 1 and the insulating layer 3, and the coating The raw materials of layer 2 include by weight: 100 parts of methacrylic silicone rubber, 45 parts of white carbon black, 10 parts of porcelain powder, 5 parts of benzophenone, 4.5 parts of triallyl isocyanurate, tensile 6 parts of strength improver, 4 parts of flame retardant, 3 parts of magnesium oxide, 6 parts of zinc stearate, 2.5 parts of zinc borate, 4 parts of iron oxide, 6 parts of hydroxyl silicone oil, 2.5 parts of titanium dioxide, 5.5 parts of gas-phase aluminum hydroxide , 6 ...

Embodiment 2

[0030] Such as figure 1 as shown, figure 1 It is a cross-sectional view of a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention.

[0031] refer to figure 1 , a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention, comprising a conductor 1 and an insulating layer 3 coated on the outer periphery of the conductor 1, a coating 2 is coated between the conductor 1 and the insulating layer 3, and the coating The raw materials of layer 2 include by weight: 80 parts of methacrylic silicone rubber, 60 parts of white carbon black, 5 parts of porcelain powder, 8 parts of benzophenone, 3 parts of triallyl isocyanurate, tensile 8 parts of strength improver, 2 parts of flame retardant, 5 parts of magnesium oxide, 4 parts of zinc stearate, 4 parts of zinc borate, 2 parts of iron oxide, 8 parts of hydroxyl silicone oil, 1 part of titanium dioxide, 8 parts of gas-phase aluminum hydroxide , 4 parts of fu...

Embodiment 3

[0038] Such as figure 1 as shown, figure 1 It is a cross-sectional view of a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention.

[0039] refer to figure 1 , a silicone rubber fire-resistant and high-voltage insulated wire proposed by the present invention, comprising a conductor 1 and an insulating layer 3 coated on the outer periphery of the conductor 1, a coating 2 is coated between the conductor 1 and the insulating layer 3, and the coating The raw materials of layer 2 include by weight: 120 parts of methacrylic silicone rubber, 30 parts of white carbon black, 15 parts of porcelain powder, 2 parts of benzophenone, 6 parts of triallyl isocyanurate, tensile 4 parts of strength improver, 6 parts of flame retardant, 1 part of magnesium oxide, 8 parts of zinc stearate, 1 part of zinc borate, 6 parts of iron oxide, 4 parts of hydroxyl silicone oil, 4 parts of titanium dioxide, 3 parts of gas phase aluminum hydroxide , 8 parts of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com