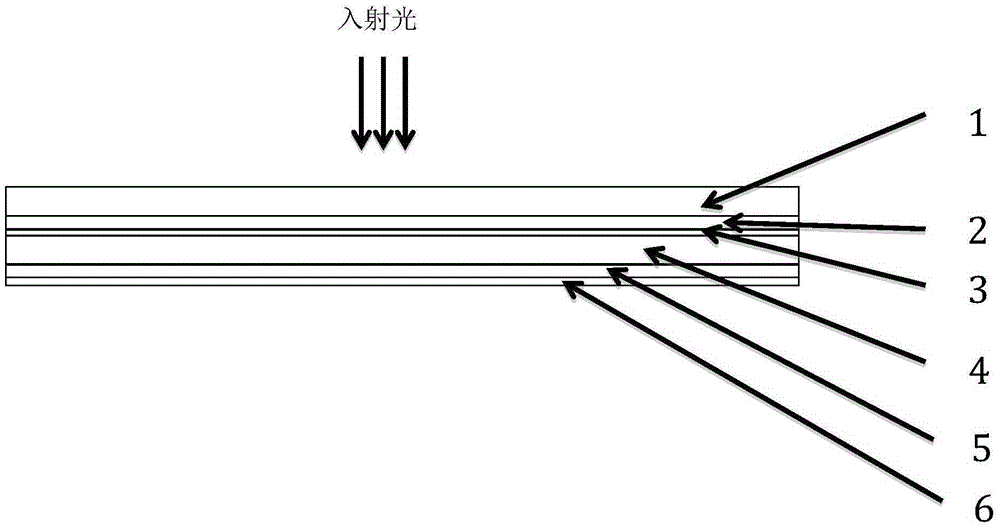

Manufacturing method for thin film crystal silicon perovskite heterojunction solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to reduce production costs, high crystallization temperature, and long crystallization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The preparation method of the thin film crystalline silicon perovskite heterojunction solar cell of this embodiment, the steps are as follows:

[0067] The first step is to prepare a P-type crystalline silicon thin film layer on the aluminum substrate:

[0068] (1.1) Preparation of P-type α-Si:H amorphous silicon thin film: Place the high-temperature-resistant opaque conductive substrate on the sample stage of PECVD equipment, and through the PECVD method, at a reaction pressure of 5Pa, a substrate temperature of 50°C, SiH 4 The gas flow rate is 0.lsccm, H 2 Gas flow rate is 1sccm, PH 3 Under the condition that the gas flow rate is 0.000lsccm, a 20nm thick P-type α-Si:H amorphous silicon film is grown on the aluminum substrate,

[0069] (1.2) Dehydrogenation of P-type α-Si:H amorphous silicon thin film: in high-purity N 2 Under the condition of atmosphere and 250°C, the P-type α-Si:H amorphous silicon film obtained in the previous step was treated for 0.1 hour to com...

Embodiment 2

[0090] In addition to the fifth step, the top electrode is prepared on the electron transport layer composed of dense titanium dioxide:

[0091] Prepare the top electrode on the electron transport layer made of dense titanium dioxide prepared in the fourth step above. The specific operation method is to prepare the AZO layer top electrode with the following magnetron sputtering device:

[0092] AZO film was prepared by magnetron sputtering device, the distance from the target to the substrate was 10cm, a thermocouple was installed near the substrate, during the whole preparation process, the substrate was rotated at a speed of 10 revolutions per minute, and the target material used was It is doped with 2% Al by weight 2 o 3 ZnO ceramic target with a purity of 99.99% by weight. The whole product obtained in the fourth step is used as the substrate, and the electron transport layer composed of dense titanium dioxide is on the top. The substrate was ultrasonically cleaned and d...

Embodiment 3

[0094] In addition to the fifth step, the top electrode is prepared on the electron transport layer composed of dense titanium dioxide:

[0095] Prepare the top electrode on the electron transport layer made of dense titanium dioxide prepared in the fourth step above. The specific operation method is to prepare the AZO layer top electrode with the following magnetron sputtering device:

[0096] AZO film was prepared by magnetron sputtering device, the distance from the target to the substrate was 10cm, a thermocouple was installed near the substrate, during the whole preparation process, the substrate was rotated at a speed of 10 revolutions per minute, and the target material used was It is doped with 2% Al by weight 2 o 3 ZnO ceramic target with a purity of 99.99% by weight. The whole product obtained in the fourth step is used as the substrate, and the electron transport layer composed of dense titanium dioxide is on the top. The substrate was ultrasonically cleaned and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com