Prefabricated engineering pipe for municipal tap water

A technology for municipal tap water and engineering pipes, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of complex processing technology and low bearing capacity of concrete prefabricated piles, to ensure pressure resistance, improve corrosion resistance, improve The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

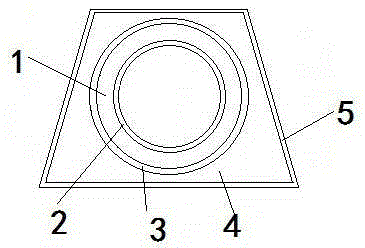

[0021] A prefabricated engineering pipe for municipal tap water, which includes an engineering pipe body whose cross-section is circular, the inner surface of the engineering pipe body is coated with a corrosion-resistant coating, the exterior of the engineering pipe body is an insulation layer, and the outer surface of the insulation layer is concrete Shell, the concrete shell has a trapezoidal cross-section, and the exterior of the concrete shell is coated with a corrosion-resistant coating.

[0022] The body of the engineering pipe is an iron-based alloy, and its elements are composed of: C0.3﹪, Mg4﹪, Ge0.8﹪, Ni0.6﹪, Cu0.4﹪, Zn0.25﹪, In0.15﹪, Ba0. 07﹪, Al0.06﹪, Ti0.03﹪, Pr0.01﹪, Sb0.01﹪, the balance is Fe,

[0023] Concrete shell consists of 40 parts of cement, 65 parts of sand, 85 parts of gravel, 10 parts of carbide slag, 7 parts of calcite powder, 8 parts of sepiolite powder, 6 parts of halloysite powder, 6 parts of silica powder, 4 parts of hematite powder, 3 parts of ...

Embodiment 2

[0026] A prefabricated engineering pipe for municipal tap water, which includes an engineering pipe body whose cross-section is circular, the inner surface of the engineering pipe body is coated with a corrosion-resistant coating, the exterior of the engineering pipe body is an insulation layer, and the outer surface of the insulation layer is concrete Shell, the concrete shell has a trapezoidal cross-section, and the exterior of the concrete shell is coated with a corrosion-resistant coating.

[0027] The body of the engineering pipe is an iron-based alloy, and its elements are composed of: C0.4﹪, Mg5﹪, Ge0.9﹪, Ni0.7﹪, Cu0.5﹪, Zn0.25﹪, In0.15﹪, Ba0. 08﹪, Al0.07﹪, Ti0.04﹪, Pr0.02﹪, Sb0.02﹪, the balance is Fe,

[0028] Concrete shell consists of 50 parts of cement, 65 parts of sand, 85 parts of gravel, 10 parts of carbide slag, 7 parts of calcite powder, 8 parts of sepiolite powder, 6 parts of halloysite powder, 6 parts of silica powder, 4 parts of hematite powder, 3 parts of ...

Embodiment 3

[0031] A prefabricated engineering pipe for municipal tap water, which includes an engineering pipe body whose cross-section is circular, the inner surface of the engineering pipe body is coated with a corrosion-resistant coating, the exterior of the engineering pipe body is an insulation layer, and the outer surface of the insulation layer is concrete Shell, the concrete shell has a trapezoidal cross-section, and the exterior of the concrete shell is coated with a corrosion-resistant coating.

[0032] The body of the engineering pipe is an iron-based alloy, and its elements are composed of: C0.35﹪, Mg4.5﹪, Ge0.85﹪, Ni0.65﹪, Cu0.45﹪, Zn0.25﹪, In0.15﹪, Ba0.075﹪, Al0.065﹪, Ti0.035﹪, Pr0.015﹪, Sb0.015﹪, the balance is Fe,

[0033] Concrete shell consists of 45 parts of cement, 65 parts of sand, 85 parts of gravel, 10 parts of carbide slag, 7 parts of calcite powder, 8 parts of sepiolite powder, 6 parts of halloysite powder, 6 parts of silica powder, 4 parts of hematite powder, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com