Preparation and application of mercury ion sensor based on photonic crystal enhanced fluorescence

A photonic crystal, enhanced fluorescence technology, used in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of expensive instruments, need professional operators, cumbersome detection process, etc., to reduce the detection concentration and detection limit, and enhance the detection signal. , the effect of high detection selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

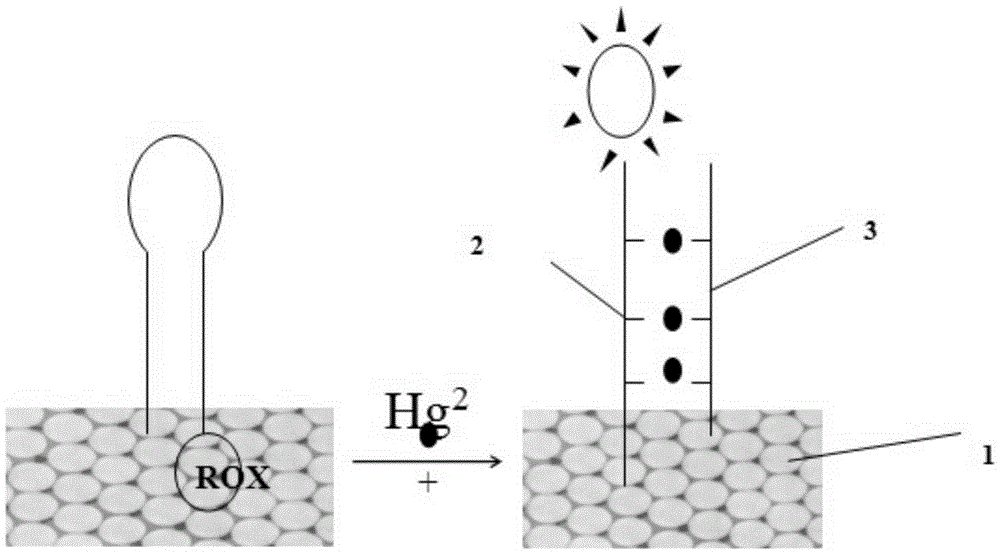

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of SiO by the improved StOber method 2 Spherical particles, prepared SiO with different particle sizes by adjusting the ratio of ammonia water and absolute ethanol 2 . Mix a certain amount of tetraethyl orthosilicate (TEOS) with absolute ethanol, and obtain a uniform TEOS solution by ultrasonication, add the above-mentioned TEOS solution to a certain amount of ammonia water and different proportions of absolute ethanol and water mixed solution, Magnetic stirring for 2 hours, centrifugal washing (washing with water and ethanol twice each), drying in a vacuum oven at 60°C for 24 hours to obtain SiO 2 Microspheres. The experimental parameters are as follows:

[0047]

[0048] 2) Synthesis of Opal photonic crystals by vertical deposition self-assembly method

[0049] The glass slides were ultrasonically cleaned in acetone, ethanol, and deionized water for 20 min, and then placed in a mixed solution (H 2 SO 4 and H 2 o 2 The volume ratio is 3:1) Soa...

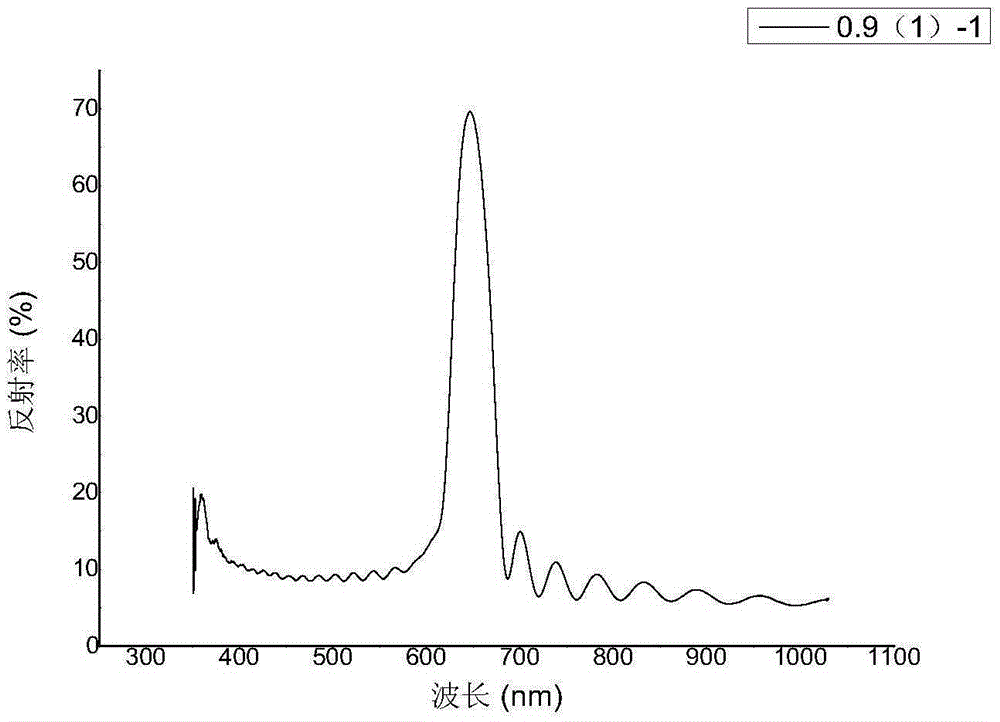

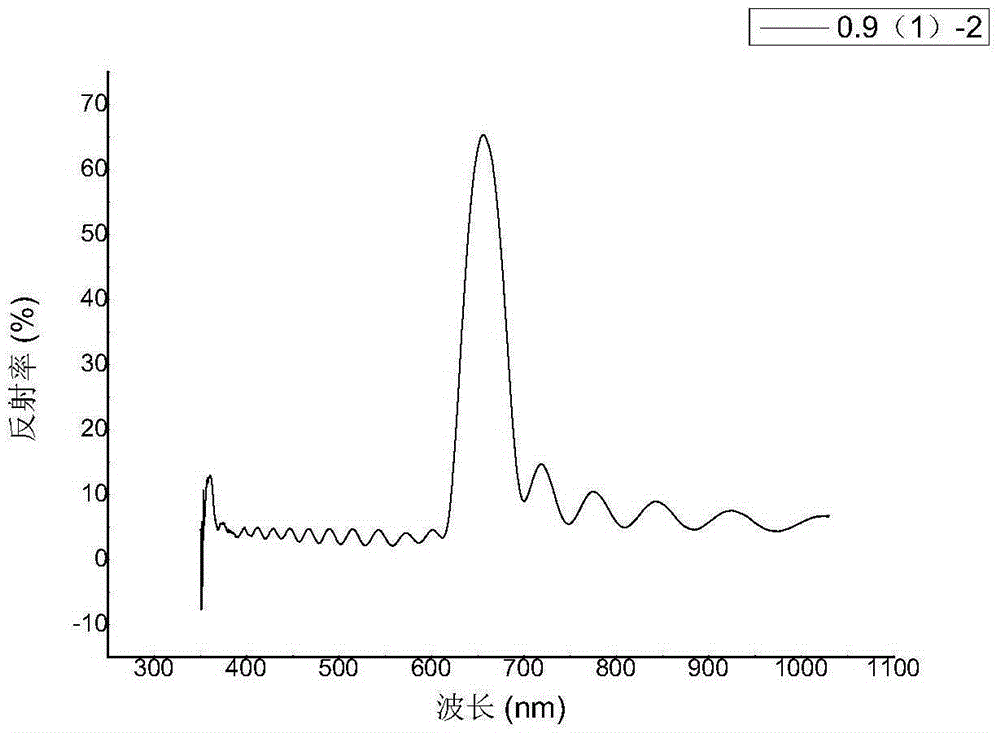

Embodiment 2

[0059] 1) Synthesis of polystyrene microspheres

[0060] Pour a certain amount of purified styrene into a separatory funnel, wash with NaOH solution and ultrapure water in sequence, then remove a small amount of residual water with anhydrous calcium chloride, and finally obtain purified styrene by vacuum distillation. At room temperature, add styrene monomer, methyl methacrylate solution, acrylic acid, ultrapure water and sodium dodecylbenzenesulfonate into a three-necked flask together, stir at 630 / min, heat in a water bath to 50°C, and keep warm for 15 minutes Add ammonium persulfate dropwise and adjust the water bath to heat to 75°C, use an ice bath to cool to room temperature, and finally use an ice bath to cool to room temperature to complete the reaction to obtain a milky white polystyrene microsphere emulsion, wherein the styrene, methyl The volume ratio of methyl acrylate solution, acrylic acid, ultrapure water and sodium dodecylbenzenesulfonate is 20:1:1:100:123;

[...

Embodiment 3

[0073] 1) Synthesis of polystyrene microspheres

[0074] Pour a certain amount of purified styrene into a separatory funnel, wash with NaOH solution and ultrapure water in sequence, then remove a small amount of residual water with anhydrous calcium chloride, and finally obtain purified styrene by vacuum distillation. At room temperature, add styrene monomer, methyl methacrylate solution, acrylic acid, ultrapure water and sodium dodecylbenzenesulfonate into a three-necked flask together, stir at a speed of 660 / min, heat to 50°C in a water bath, and keep warm for 15 minutes Add the ammonium persulfate dropwise and adjust the water bath to heat to 85°C, use an ice bath to cool to room temperature, and finally use an ice bath to cool to room temperature to complete the reaction to obtain a milky white polystyrene microsphere emulsion, wherein the styrene, methyl The volume ratio of methyl acrylate solution, acrylic acid, ultrapure water and sodium dodecylbenzenesulfonate is 20:1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com