graphene/cnts/super-p composite conductive agent, composite conductive agent slurry and preparation method thereof

A technology of composite conductive agent and slurry, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of not having and not meeting, and achieve the effects of convenient application, effective contact, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

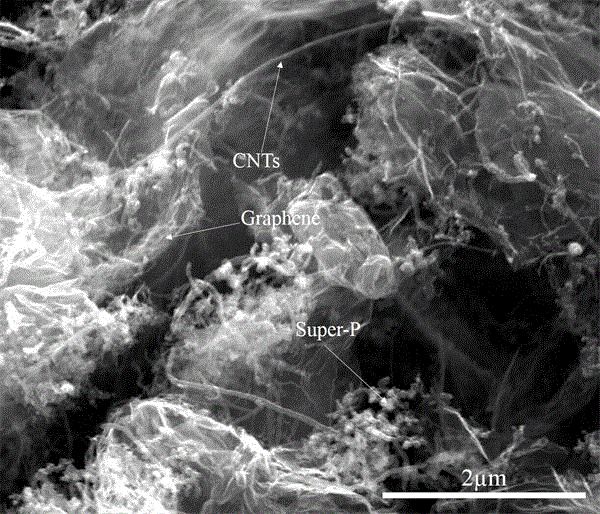

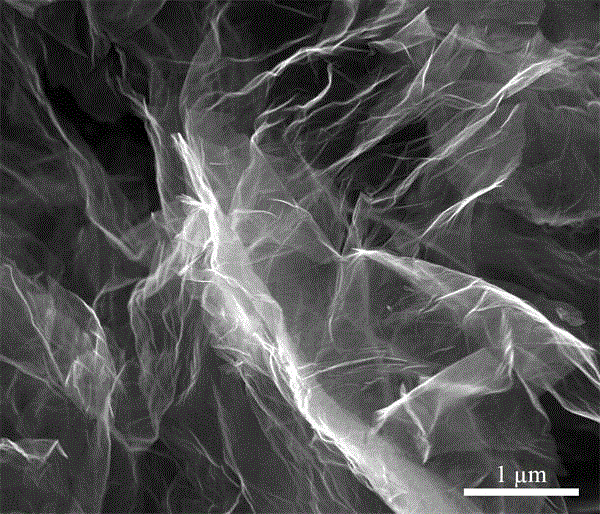

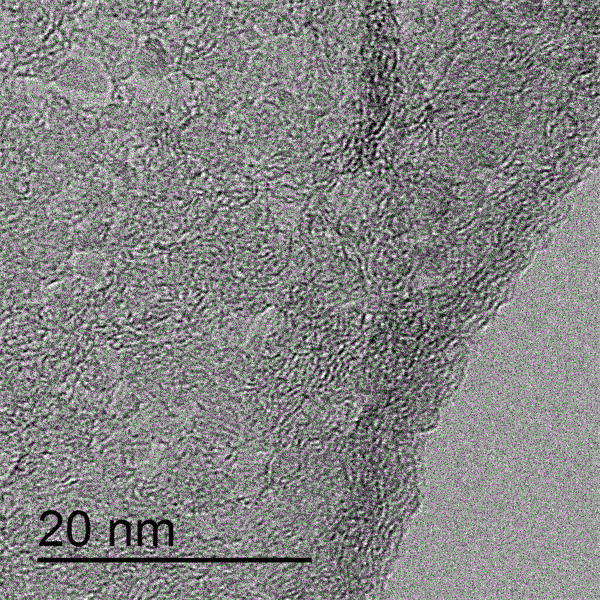

Image

Examples

Embodiment 1

[0041] Embodiment 1. A kind of preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0042] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 10% into a single-layer glass reactor, add 5g of CNTs, 5g of Super-P and 0.2g of surfactant polyvinylpyrrolidone, mechanically stir for 30min, and then ultrasonically disperse 30min, make it mix evenly;

[0043] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0044] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0045] (4) Reduction: The mixture in step (3) was placed in a tube furnace a...

Embodiment 2

[0057] Embodiment 2. A kind of preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0058] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 20% into a single-layer glass reactor, add 10g of CNTs, 10g of Super-P and 0.4g of surfactant polyvinylpyrrolidone, mechanically stir for 30min, and then ultrasonically disperse 30min, make it mix evenly;

[0059] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0060] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0061] (4) Reduction: The mixture in step (3) was placed in a tube furnace...

Embodiment 3

[0065] Embodiment 3. A kind of preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0066] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 5% into a single-layer glass reactor, add 2.5g of CNTs, 2.5g of Super-P and 0.1g of surfactant polyvinylpyrrolidone, stir mechanically for 30min, and then Ultrasonic dispersion for 30 minutes to make it evenly mixed;

[0067] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0068] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0069] (4) Reduction: The mixture in step (3) was placed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com