Graphene/CNTs/Super-P composite electric conduction agent, composite electric conduction agent slurry, and preparation methods of graphene/CNTs/Super-P composite electric conduction agent and composite electric conduction agent slurry

A technology of composite conductive agent and slurry, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as unsatisfactory and non-existent, and achieve the effects of convenient application, improved electronic conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

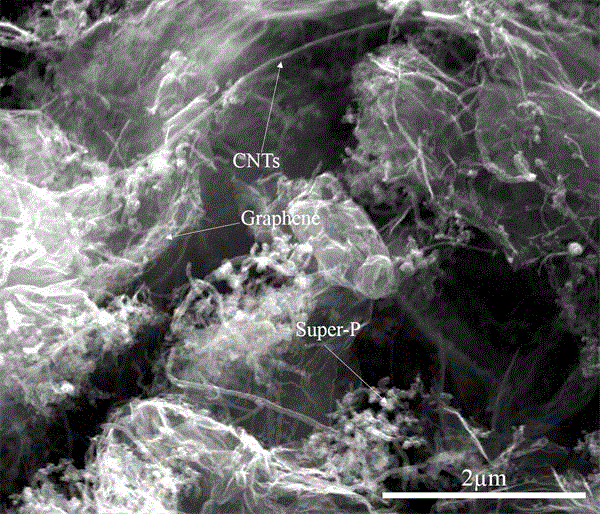

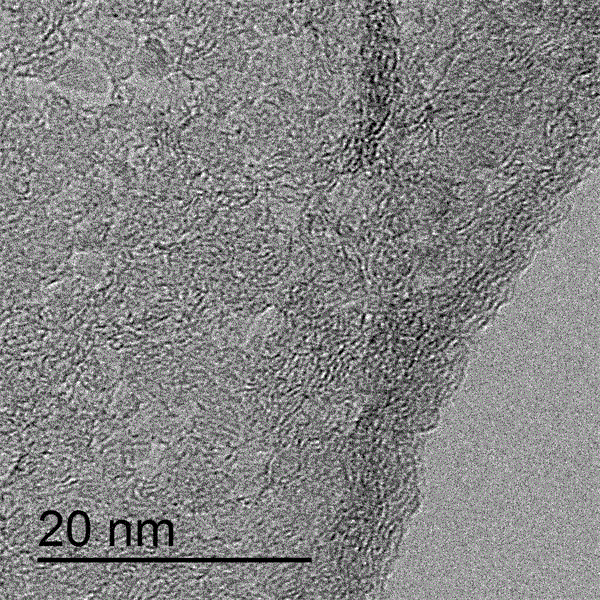

Image

Examples

Embodiment 1

[0041] Example 1. A preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0042] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 10% into a single-layer glass reactor, add 5g of CNTs, 5g of Super-P and 0.2g of surfactant polyvinylpyrrolidone, mechanically stir for 30min, and then ultrasonically disperse for 30min , to make it evenly mixed;

[0043] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0044] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0045] (4) Reduction: The mixture in step (3) was placed in a tube furnace ...

Embodiment 2

[0057] Example 2. A preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0058] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 20% into a single-layer glass reactor, add 10g of CNTs, 10g of Super-P and 0.4g of surfactant polyvinylpyrrolidone, mechanically stir for 30min, and then ultrasonically disperse for 30min , to make it evenly mixed;

[0059] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0060] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0061] (4) Reduction: The mixture in step (3) was placed in a tube furnac...

Embodiment 3

[0065] Example 3. A preparation method of Graphene / CNTs / Super-P composite conductive agent, its concrete steps are as follows:

[0066] (1) Mixing: Add 100g of graphene oxide slurry with a solid content of 5% into a single-layer glass reactor, add 2.5g of CNTs, 2.5g of Super-P and 0.1g of surfactant polyvinylpyrrolidone, stir mechanically for 30min, and then sonicate Disperse for 30 minutes to make it evenly mixed;

[0067] (2) Pulverization: Suction filter the mixed slurry in step (1), and dry it at 100°C until the water content is ≤5%, and pulverize the dried solid with a pulverizer so that the particle size of the pulverized particles is ≤74μm;

[0068] (3) Expansion: Heat the muffle furnace to raise the temperature to 300°C, quickly put the mixture particles pulverized in step (2) into the muffle furnace, puff them in the air for 5 minutes, take them out quickly, and cool to room temperature;

[0069] (4) Reduction: The mixture in step (3) was placed in a tube furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com