Nano microsphere niobium-based composite oxide and preparation method thereof

A composite oxide, nano-microsphere technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of negative impact on cycle performance, large specific surface area of materials, poor processing performance, etc. , to achieve the effect of short electronic conduction path, high capacity and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] TiNb 1.98 Zr 0.02 o 7 ——0.1C

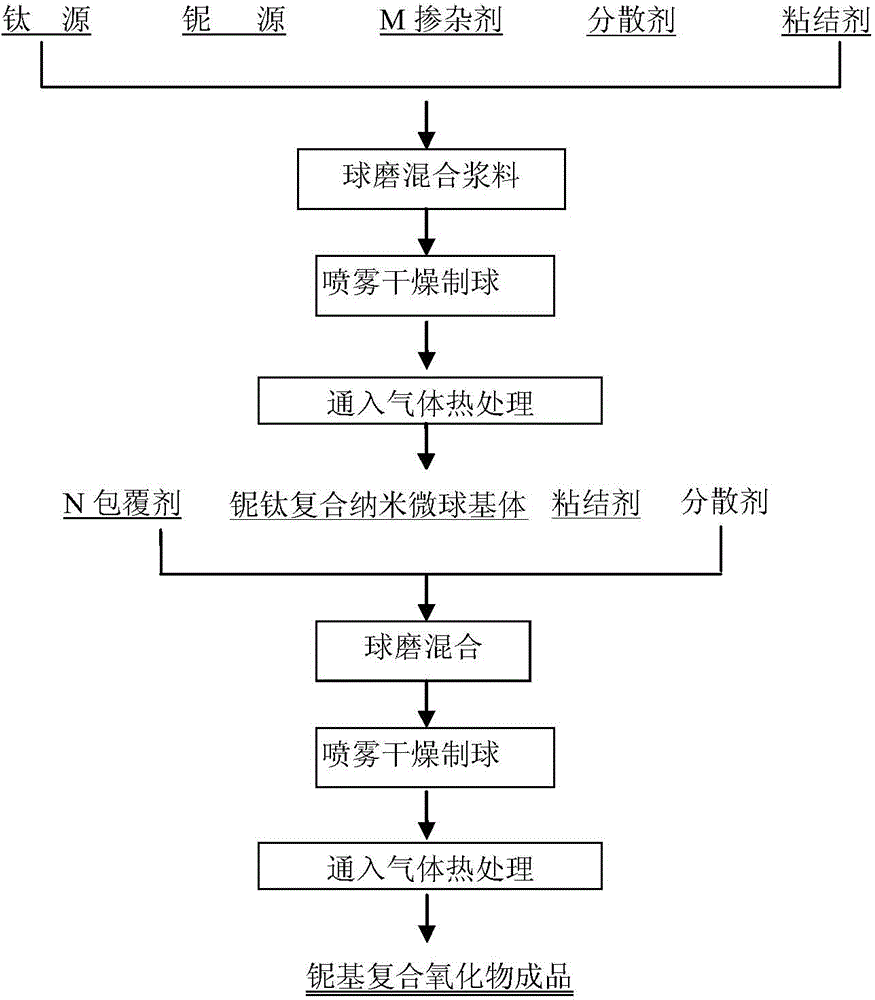

[0040] according to figure 1 As shown in the process flow, 50nm anatase titanium dioxide, 50nm niobium hydroxide and zirconium hydroxide are first selected as raw materials, and the molar ratio Ti:Nb:Zr=1:1.98:0.02 is used as ingredients, and at the same time, 1 wt% of the solid material mass is added. Sodium methyl cellulose is used as a binder, and absolute ethanol is used as a dispersant. After mixing, the solid content of the slurry is 50wt (mass)%. After mixing and ball milling, spray granulation under the condition that the inlet temperature of the hot air nozzle is 150°C , where the slurry inlet velocity is 20ml / min and the gas inlet velocity is 30m 3 / h, the outlet temperature is 80°C, and the precursor of niobium-titanium composite nanospheres is obtained, which is placed in a muffle furnace and blown with air. TiNb 1.98 Zr 0.02 o 7 matrix. Then choose glucose as the carbon source of the coating agent, according to the sy...

Embodiment 2

[0042] TiNb 1.97 Mg 0.03 o 7 ——0.1TiO 2

[0043] according to figure 1 As shown in the process flow, 100nm anatase titanium dioxide, 80nm niobium oxide, and magnesium hydroxide are first selected as raw materials, and the molar ratio of Ti:Nb:Mg=1:1.97:0.03 is used as ingredients, and at the same time, 2 wt% of the solid material is added. Glycol is the binder, and absolute ethanol is the dispersant. After mixing, the solid content of the slurry is 60wt%. After ball milling, the inlet temperature of the hot air nozzle is 180°C and the spray granulation is performed, wherein the slurry inlet flow rate is 15ml. / min, the gas inlet velocity is 30m 3 / h, the outlet temperature is 130°C, and the precursor of niobium-titanium composite nanospheres is obtained, which is placed in a muffle furnace and blown with air. TiNb 1.97 Mg 0.03 o 7 matrix. Then choose amorphous titanium dioxide as the coating agent, according to the synthesis target product TiNb 1.97 Mg 0.03 o 7 :T...

Embodiment 3

[0045] TiNb 1.99 Al 0.01 o 7 ——0.1ZrO 2

[0046] according to figure 1 The process flow shown, first selects 20nm metatitanic acid, 10nm niobium oxalate, and aluminum hydroxide as raw materials, according to the molar ratio of Ti:Nb:Al=1:1.99:0.01 ingredients, and simultaneously adds 3 wt% of the solid material mass of glucose as a viscous Binder, absolute ethanol is the dispersant, the solid content of the slurry after mixing is 40wt%, after ball milling, the inlet temperature of the hot air nozzle is spray granulation under the condition of 130 ℃, wherein, the slurry inlet flow rate is 15ml / min, the gas The inlet velocity is 30m 3 / h, the outlet temperature is 90°C, and the precursor of niobium-titanium composite nanospheres is obtained, which is placed in a muffle furnace and blown with air. TiNb 1.99 Al 0.01 o 7 matrix. Then choose zirconium hydroxide as the coating agent, according to the synthesis target product TiNb 1.99 Al 0.01 o 7 : ZrO 2 (mol%)=1:0.1 We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com