Anti-static polyformaldehyde and preparation method thereof

A polyoxymethylene, antistatic technology, applied in the field of antistatic polyoxymethylene and its preparation, can solve the problems of poor thermal stability, charge accumulation, difficult antistatic, etc., to improve tensile strength and elongation at break, antistatic Performance and long-lasting stability, the effect of improving the heat and oxygen aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

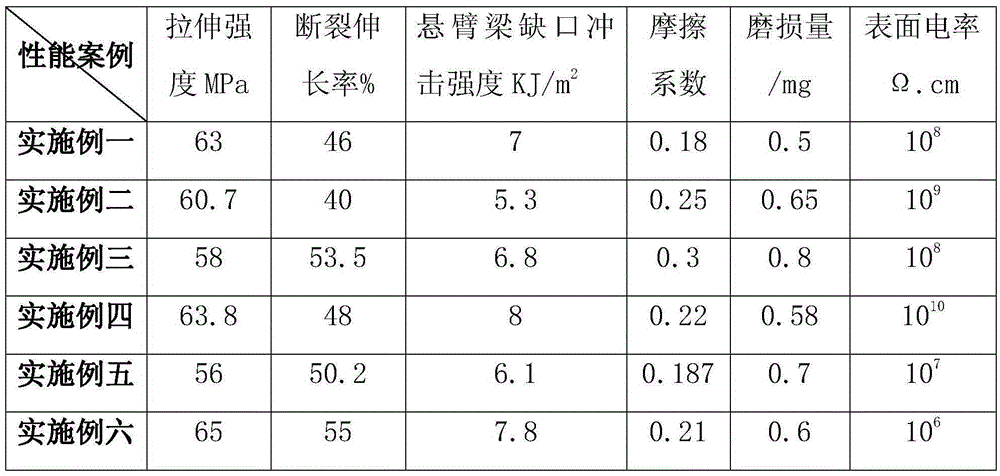

Examples

preparation example Construction

[0022] The present invention also discloses a preparation method of antistatic polyoxymethylene, comprising the following steps:

[0023] a. Polyoxymethylene, polyethylene glycol oleate, dimethyl hydroxyethyl stearylamide ethyl quaternary ammonium nitrate, polyethylene terephthalate, copolymerized nylon, magnesium oxide, copper powder, Antioxidant, light stabilizer, and lubricant are mixed according to the set weight ratio and then added to the extruder, extruded and granulated under reduced pressure and molten state;

[0024] b. Obtain antistatic polyoxymethylene after drying the product pellets of step a.

Embodiment 1

[0026] The antistatic polyoxymethylene of the present embodiment includes the following raw material components in parts by weight: 100 parts of polyoxymethylene, 5 parts of polyethylene glycol oleate, dimethyl hydroxyethyl stearamidoethyl quaternary ammonium nitrate 3 parts, 3 parts of polyethylene terephthalate, 4 parts of copolymerized nylon, 5 parts of magnesium oxide, 3 parts of copper powder, 2 parts of antioxidant, 1 part of light stabilizer, and 1 part of lubricant.

[0027] In this embodiment, the antioxidant is 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, according to this embodiment Parts by weight Replace 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene with 2,4-bis(n-octylsulfide Methylene)-6-methylphenol, 4,4'-methylenebis(2,6-di-tert-butylphenol), tris-(3,5-di-tert-butyl-4-hydroxybenzyl) Similar effects can be achieved when one or more mixtures of isocyanurate and 2,2'-methylenebis(6-cyclohexyl-4-methylphenol) are us...

Embodiment 2

[0032] The antistatic polyoxymethylene of the present embodiment includes the following raw material components in parts by weight: 100 parts of polyoxymethylene, 12 parts of polyethylene glycol oleate, dimethyl hydroxyethyl stearamidoethyl quaternary ammonium nitrate 8 parts, 8 parts of polyethylene terephthalate, 10 parts of copolymerized nylon, 12 parts of magnesium oxide, 10 parts of copper powder, 6 parts of antioxidant, 4 parts of light stabilizer, and 10 parts of lubricant.

[0033]In the present embodiment, the antioxidant is 2,4-bis(n-octylthiomethylene)-6-methylphenol, and 2,4-bis(n-octylthiomethylene) Methylene)-6-methylphenol was replaced by 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 4,4 '-methylenebis(2,6-di-tert-butylphenol), tris-(3,5-di-tert-butyl-4-hydroxybenzyl)isocyanurate, 2,2'-methylene When one or more mixtures of two (6-cyclohexyl-4-methylphenol) have similar effects.

[0034] In this example, the light stabilizer is 2-(2'-3'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com