Thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheathing material for nuclear power plant cables

A nuclear power plant cable, low-smoke flame-retardant technology, applied in plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problems of electronic residue, cable sheath cracking, insufficient to meet large-section thick sheathed cables, etc. Achieve the effect of high flame retardant performance and improved thermal oxygen aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

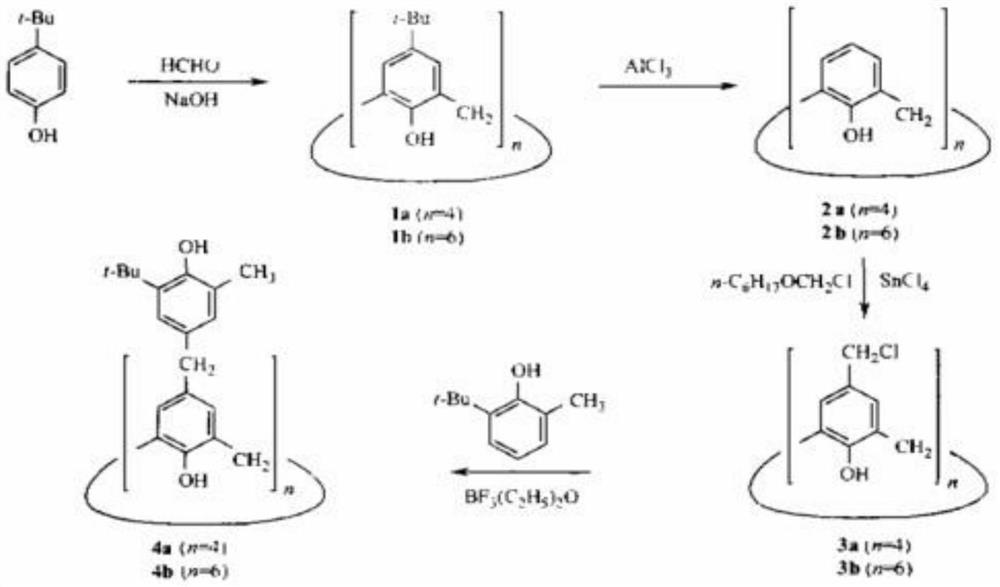

Method used

Image

Examples

Embodiment 1

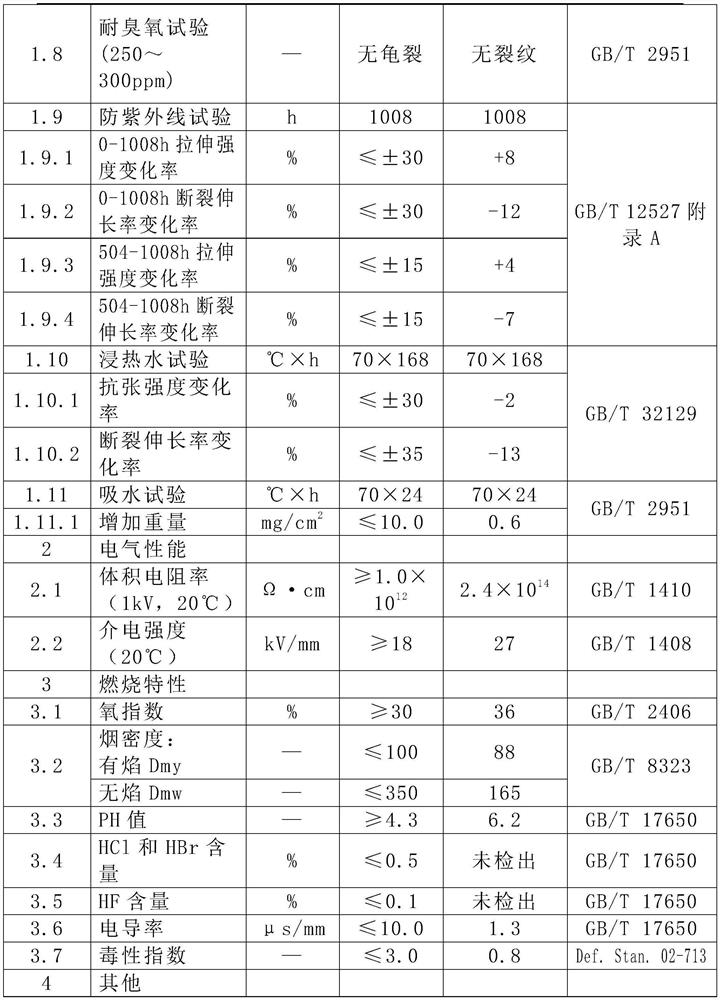

[0038] The thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheath material for nuclear power plant cables in this embodiment is composed of the following components by weight:

[0039] Base material: 100 parts, wherein the base material is a mixture of high temperature resistant polyolefin elastomer NOTIO PN-3560 and ethylene-methyl methacrylate copolymer (EMMA), and high temperature resistant polyolefin elastomer NOTIO PN-3560 and ethylene- The mass ratio of methyl methacrylate copolymer is 10:1, and the high temperature resistant polyolefin elastomer NOTIO PN-3560 is a product produced by Japan's Mitsui Company, which can be obtained directly by purchase;

[0040] High temperature and radiation resistant modified masterbatch: 30, and the high temperature and radiation resistant modified masterbatch contains at least condensed polycyclic polynuclear aromatic hydrocarbon resin and high temperature and radiation resistant resin polyphenylene sulfone micr...

Embodiment 2

[0048] The thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheath material for nuclear power plant cables in this embodiment is composed of the following components by weight:

[0049] Base material: 100 parts, wherein the base material is a mixture of high temperature resistant polyolefin elastomer NOTIO PN-2070 and ethylene-methyl methacrylate copolymer (EMMA), and high temperature resistant polyolefin elastomer NOTIO PN-2070 and ethylene- The mass ratio of methyl methacrylate copolymer is 10:0.5. The high temperature resistant polyolefin elastomer NOTIO PN-2070 here is a product produced by Japan's Mitsui Company and can be obtained directly by purchase;

[0050] High temperature and radiation resistance modified masterbatch: 40; flame retardant: 150, and the flame retardant is a mixture of aluminum hydroxide, zinc borate and kaolin, and the mass ratio of aluminum hydroxide, zinc borate and kaolin is 8:1:1 ; Antioxidant: 12, antioxidant is asymmetri...

Embodiment 3

[0054] The thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheath material for nuclear power plant cables in this embodiment is composed of the following components by weight:

[0055] Base material: 100 parts, wherein the base material is a mixture of high temperature resistant polyolefin elastomer NOTIO PN-3560, ethylene-methyl methacrylate copolymer (EMMA) and ethylene-vinyl acetate copolymer, and high temperature resistant polyolefin elastic The mass ratio of body NOTIO PN-3560, ethylene-methyl methacrylate copolymer and ethylene-vinyl acetate copolymer is 10:2.0:1.0. The high temperature resistant polyolefin elastomer NOTIO PN-3560 is produced by Japan's Mitsui Co., Ltd. products can be obtained directly by purchasing;

[0056] High temperature and radiation resistance modified masterbatch: 40; flame retardant: 150, and the flame retardant is a mixture of aluminum hydroxide, zinc borate and kaolin, and the mass ratio of aluminum hydroxide, zinc bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com