A kind of medical orthodontic forceps and the processing method of medical orthodontic forceps knife edge

A processing method and cutting edge technology, which are applied in the field of medical orthodontic forceps and the processing of the edge of medical orthodontic forceps, can solve the problems of poor bonding force between alloy sheets and substrates, easy corrosion of inlays, complex processes, etc., and achieve the goal of using Improved life and performance, less prone to chipping and breakage, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

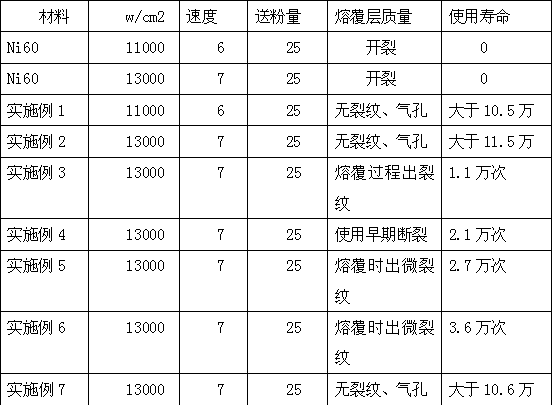

Examples

Embodiment 1

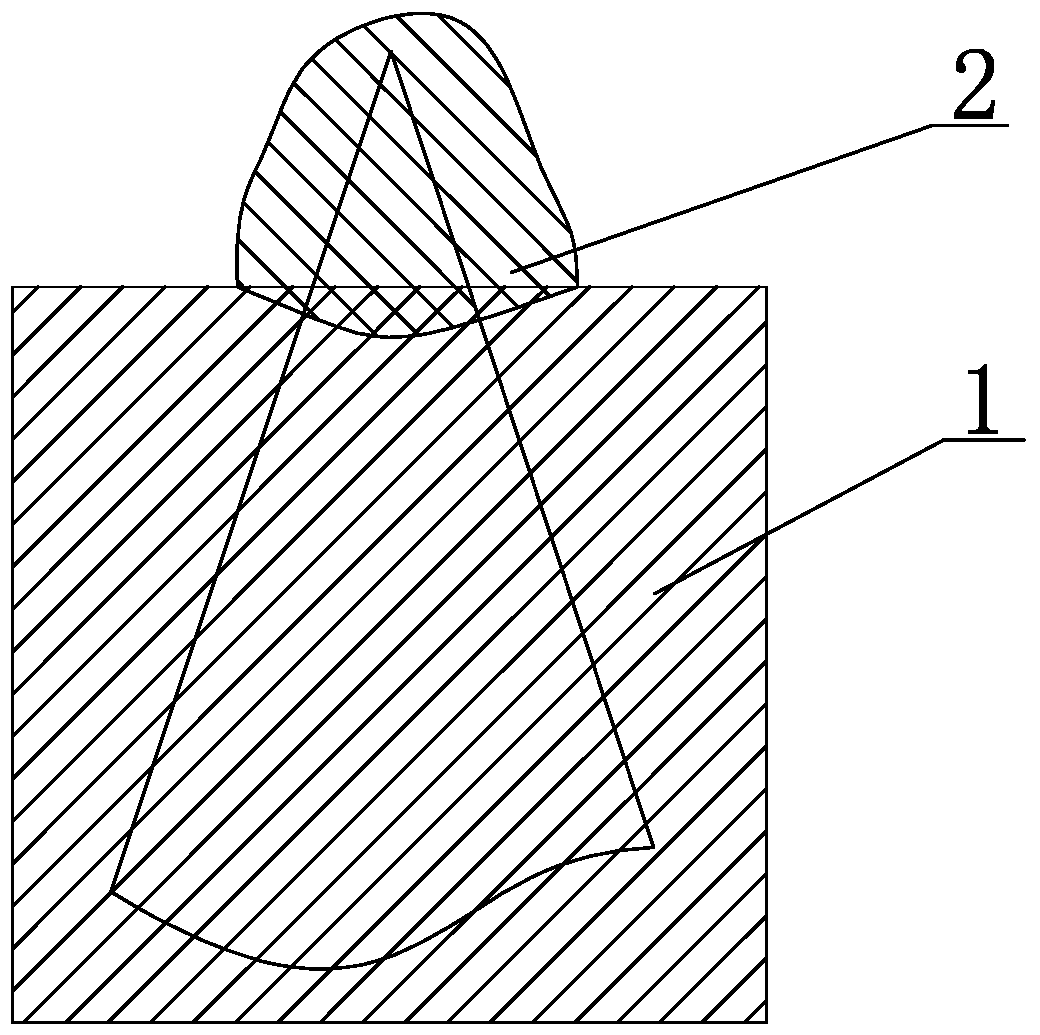

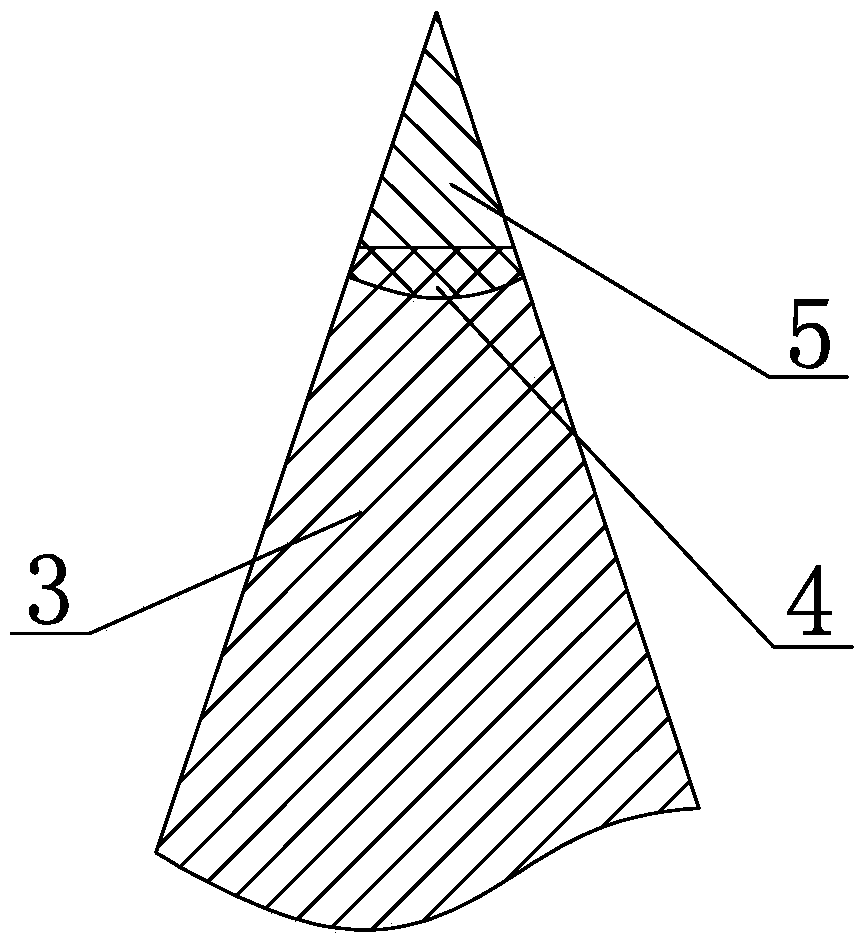

[0017] Such as figure 1 and figure 2 A medical orthodontic pliers and a method for processing the edge of the medical orthodontic pliers include the following steps:

[0018] 1. According to the chemical composition (weight percentage) of alloying elements, C: 0.4%, Cr: 22%, W: 3.5%, Mo: 1.5%, Ni: 2%, Si: 1.5%, B: 0.6%, Nb: 1.5 %, RE: 0.3% and Fe: balance. Calculate the addition amount of each master alloy such as ferrochromium, ferrotungsten molybdenum, ferrosilicon, and ferroboron (the different burning loss rates of each element are considered in the calculation).

[0019] 2. Melt and powder in the intermediate frequency furnace according to the conventional method, that is, add high melting point elements and various intermediate alloys (ferrochromium, ferromolybdenum, ferroboron, etc.) Slag, after refining, add rare earth RE (Ce, La mixed rare earth) and homogenize; carry out gas atomization powder at about 1400 ℃, sieve and store the powder after drying, choose -140+...

Embodiment 2

[0025] Such as figure 1 and figure 2 A medical orthodontic pliers and a method for processing the edge of the medical orthodontic pliers include the following steps:

[0026] 1. According to the chemical composition (weight percentage) of alloying elements, C: 0.45%, Cr: 25%, W: 4.0%, Mo: 1.5%, Ni: 3%, Si: 2.0%, B: 0.5%, Nb: 2.5 %, RE: 0.5% and Fe: balance. Calculate the addition amount of each master alloy such as ferrochromium, ferrotungsten molybdenum, ferrosilicon, and ferroboron (the different burning loss rates of each element are considered in the calculation).

[0027] 2. Melt and powder in the intermediate frequency furnace according to the conventional method, that is, add high melting point elements and various intermediate alloys (ferrochromium, ferromolybdenum, ferroboron, etc.) Slag, after refining, add rare earth RE (Ce, La mixed rare earth) and homogenize; carry out gas atomization powder at about 1400 ℃, sieve and store the powder after drying, choose -140...

Embodiment 3

[0033] Such as figure 1 and figure 2 A medical orthodontic pliers and a method for processing the edge of the medical orthodontic pliers include the following steps:

[0034] 1. According to the chemical composition (weight percentage) of alloying elements, C: 0.6%, Cr: 28%, W: 4.0%, Mo: 1.5%, Ni: 3%, Si: 2.0%, B: 0.5%, Nb: 2.5 %, RE: 0.5% and Fe: balance. Calculate the addition amount of each master alloy such as ferrochromium, ferrotungsten molybdenum, ferrosilicon, and ferroboron (the different burning loss rates of each element are considered in the calculation).

[0035] 2. Melt and powder in the intermediate frequency furnace according to the conventional method, that is, add high melting point elements and various intermediate alloys (ferrochromium, ferromolybdenum, ferroboron, etc.) Slag, after refining, add rare earth RE (Ce, La mixed rare earth) and homogenize; carry out gas atomization powder at about 1400 ℃, sieve and store the powder after drying, choose -140+32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com