High-voltage electrical insulating tape and preparing method thereof

A technology for insulating tapes and high-voltage electrical appliances, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. Meet the requirements of insulation and sealing, damage the sealing performance and electrical insulation performance, etc., achieve long-term insulation effect, avoid the entry of water vapor, and improve the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

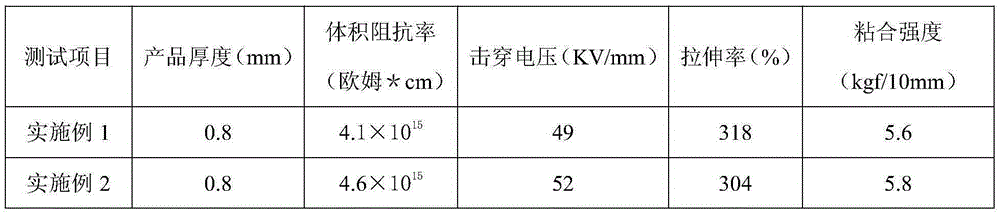

Embodiment 1

[0021] The base film is made of polypropylene, and the mass ratio of the colloidal layer is as follows: 10 parts of polytetrafluoroethylene rubber, 15 parts of isobutylene ethylene copolymer, 25 parts of ethylene oxide propylene oxide copolymer, 10 parts of nano-alumina, superfine 30 parts of talcum powder, 0.5 parts of rosin, 5.0 parts of dimethylsiloxane, 1.0 parts of phenolic resin, 1.0 parts of carbon black, 1.0-2.0 parts of dioctyl phthalate, and 1.5-3.0 parts of diphenylamine. The mass ratio of the pressure-sensitive layer is 20 parts of polymethacrylate, 50 parts of hydrogenated copolymer of isoprene and butadiene

[0022] The preparation method of the adhesive tape comprises the following steps: the production of the base film, the base film is selected from polypropylene particles, and the required base film is made through extrusion, film pressing, winding, and unwinding; refining masterbatch; first, polytetrafluoroethylene Ethylene rubber and isobutylene ethylene co...

Embodiment 2

[0024] The base film is made of polypropylene, and the mass ratio of the colloidal layer is as follows: 20 parts of polytetrafluoroethylene rubber, 30 parts of isobutylene ethylene copolymer, 15 parts of ethylene oxide propylene oxide copolymer, 20 parts of nano-alumina, superfine 20 parts of talcum powder, 1.5 parts of rosin, 1.0 parts of dimethylsiloxane, 1.5 parts of phenolic resin, 2.0 parts of carbon black, 1.0 parts of diisooctyl phthalate, and 3.0 parts of dithiocarbamate. The mass ratio of the pressure sensitive layer is 30 parts of polymethacrylate, 40 parts of hydrogenated copolymer of isoprene and butadiene

[0025] The preparation method of the adhesive tape comprises the following steps: the production of the base film, the base film is selected from polypropylene particles, and the required base film is made through extrusion, film pressing, winding, and unwinding; refining masterbatch; first, polytetrafluoroethylene Ethylene rubber and isobutylene ethylene copol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com