A preparation method of nano-doped intelligent dimming film

An intelligent dimming and nano-technology, applied in coatings and other directions, can solve problems such as uneven dispersion, achieve good dispersion activity, improve electro-optic performance, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for a nano-doped intelligent dimming film, comprising the following steps:

[0028] (1) At first, titanium dioxide nanoparticles are prepared by solvothermal synthesis, and a titanium dioxide nanoparticle crystal gel with strong dispersion activity is formed, as follows:

[0029] Dissolve tetrabutyl titanate in ethanol solvent, adjust the pH value, add a small amount of deionized water, stir for several hours, add tetrabutyl titanate mixed solution into deionized water dropwise, tetrabutyl titanate and deionized The molar mixing ratio of ionic water is 1:90, heat treatment in the reactor at 150°C for 8 hours, and agglomerated titanium dioxide nanoparticle crystal gel with strong dispersion activity is obtained after heat treatment;

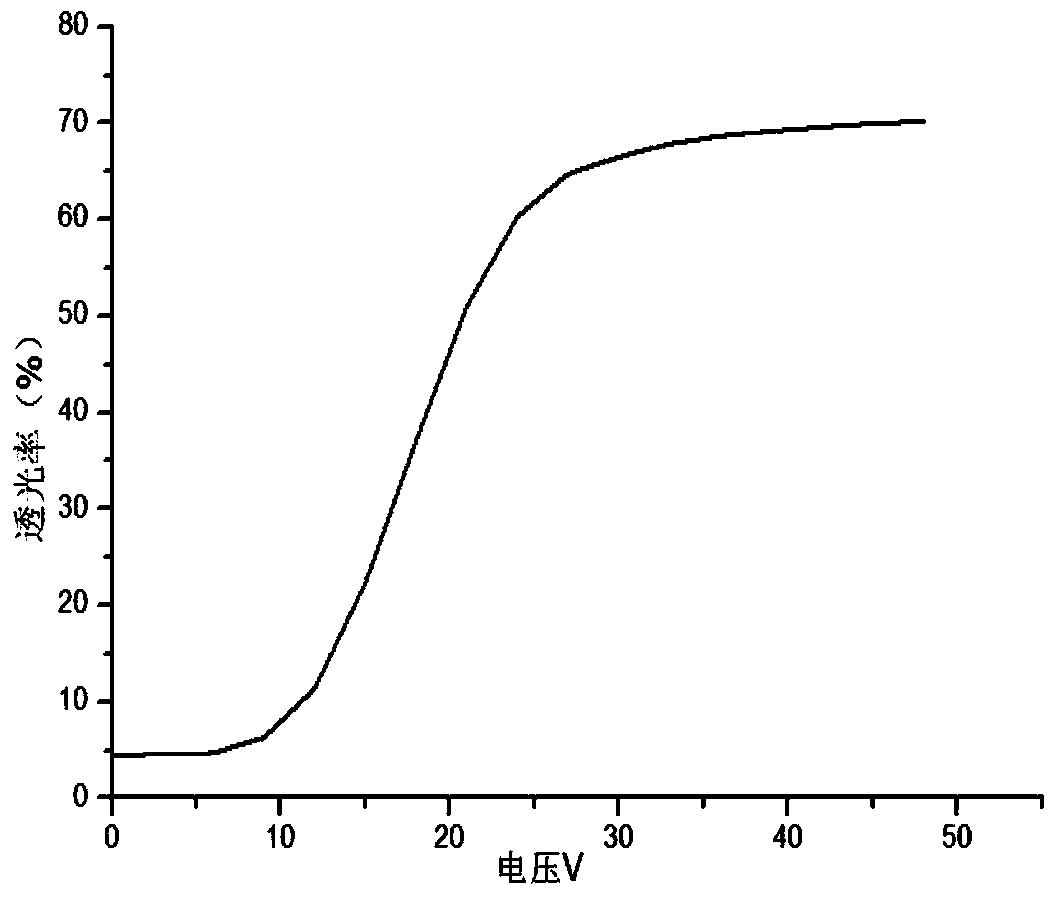

[0030] (2) Add the nanoparticle crystal gel with strong dispersing activity and coupling agent KH-570 to the intelligent dimming film prepolymer NOA65, and use the stirring-assisted ultrasonic dispersion method for 3-5h...

Embodiment 2

[0035] A preparation method for a nano-doped intelligent dimming film, comprising the following steps:

[0036] (1) At first, the nanoparticles are prepared by the hydrothermal method, and a nano-anatase crystal gel with strong dispersion activity is formed, as follows:

[0037] Take tetrabutyl titanate and slowly drop it into deionized water to form a white precipitate. After cleaning and centrifuging the precipitate, take the precipitate and stir it in deionized water for 10-12 hours, and then heat-treat it in the reactor at 180°C for 8 hours. After heat treatment, nano anatase crystal gel with strong dispersion activity is obtained;

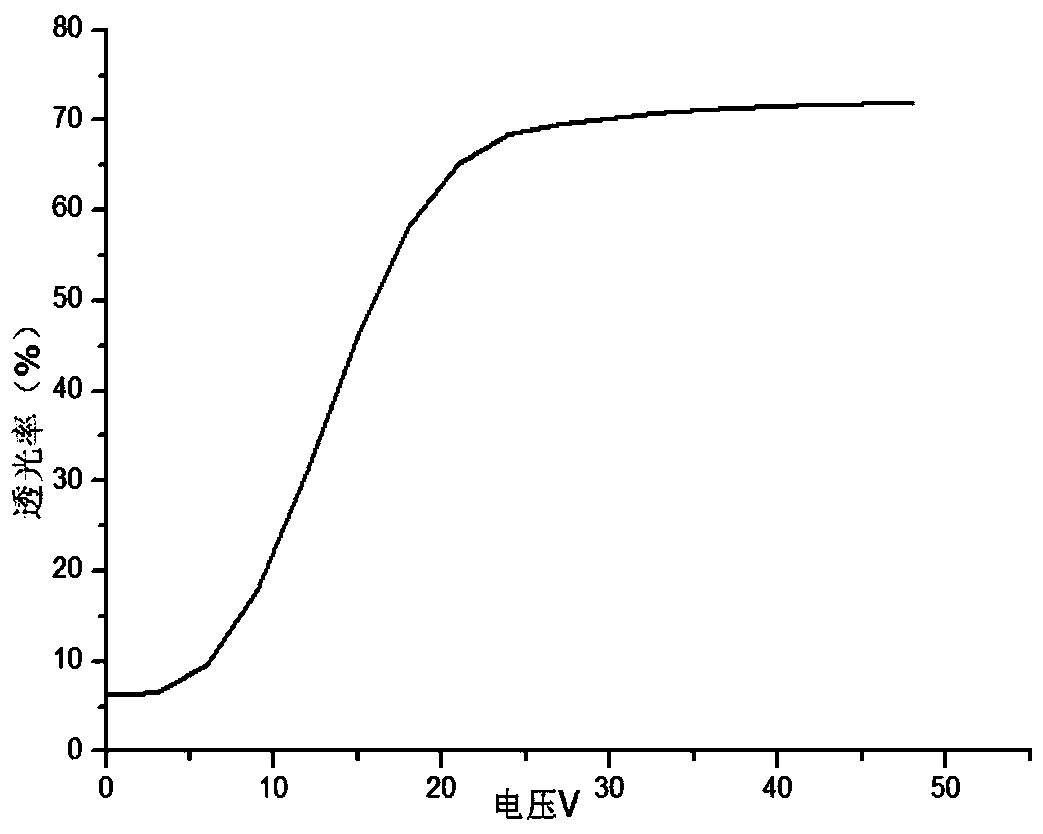

[0038] (2) Add nano-anatase crystal gel with strong dispersing activity and coupling agent KH-570 to NOA65 intelligent dimming film prepolymer, and mix it uniformly for 3-5 hours by stirring-assisted ultrasonic dispersion method to form a prepolymer Polymer nano sol, wherein the mass ratio of titanium dioxide nanoparticle crystal gel with str...

Embodiment 3

[0043] A preparation method for a nano-doped intelligent dimming film, comprising the following steps:

[0044] (1) At first, nanoparticles are prepared by solvothermal synthesis, and a nano-tin antimony oxide crystal gel with strong dispersion activity is formed, as follows:

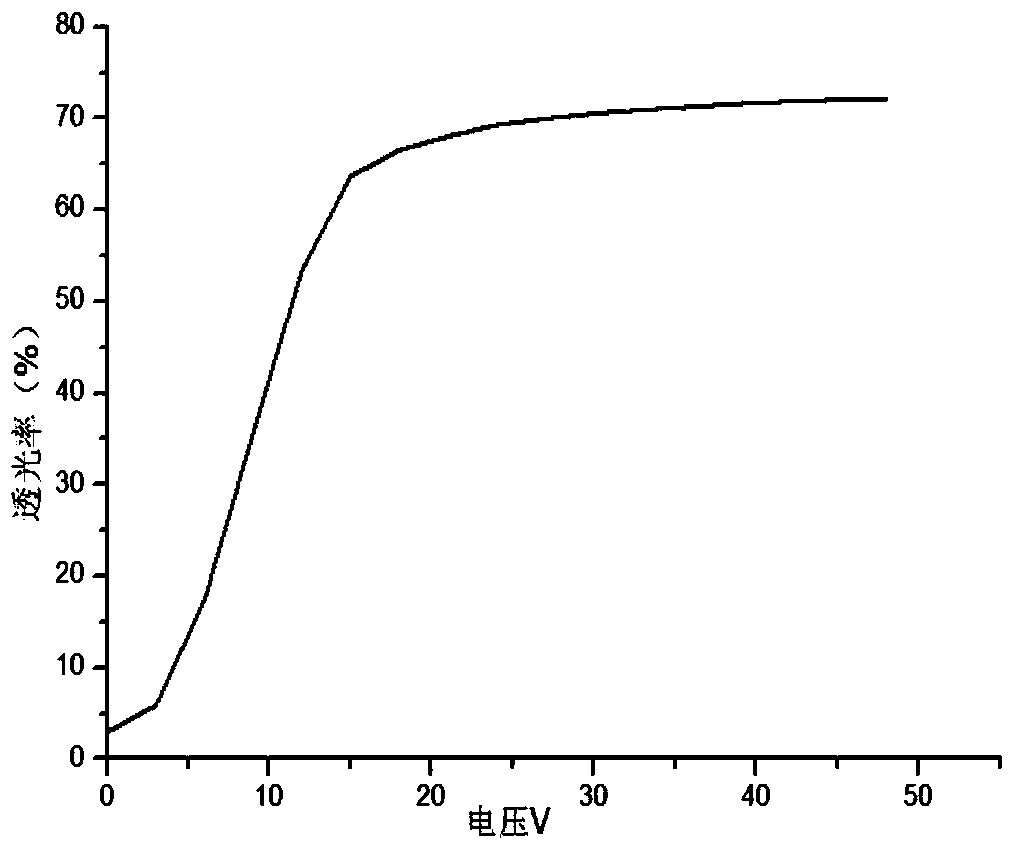

[0045] Dissolve tin tetrachloride and antimony trichloride in ethanol solution, add deionized water, add ammonia water, form a light yellow precipitate, wash, centrifuge and precipitate until there are no impurity ions in the precipitate, take the precipitate and stir in deionized water to form a chemical solution After 10-12 hours, add oxalic acid and hydrogen peroxide, heat treatment in the reactor at 210°C for 10 hours, and obtain nano-antimony tin oxide crystal gel with strong dispersion activity;

[0046](2) Add nano-tin antimony oxide crystal gel with strong dispersing activity and coupling agent KH-560 to the intelligent dimming film prepolymer NOA65, and mix it uniformly for 3-5 hours by stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com