Preparing method for three-dimensional nanometer porous graphene

A porous graphene, nanoporous technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the rare research results of three-dimensional graphene with nanoscale pore structure and controllable pore structure problems such as poor reproducibility and repeatability, performance discount of 3D graphene, etc., to achieve the effect of low cost, cost saving and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

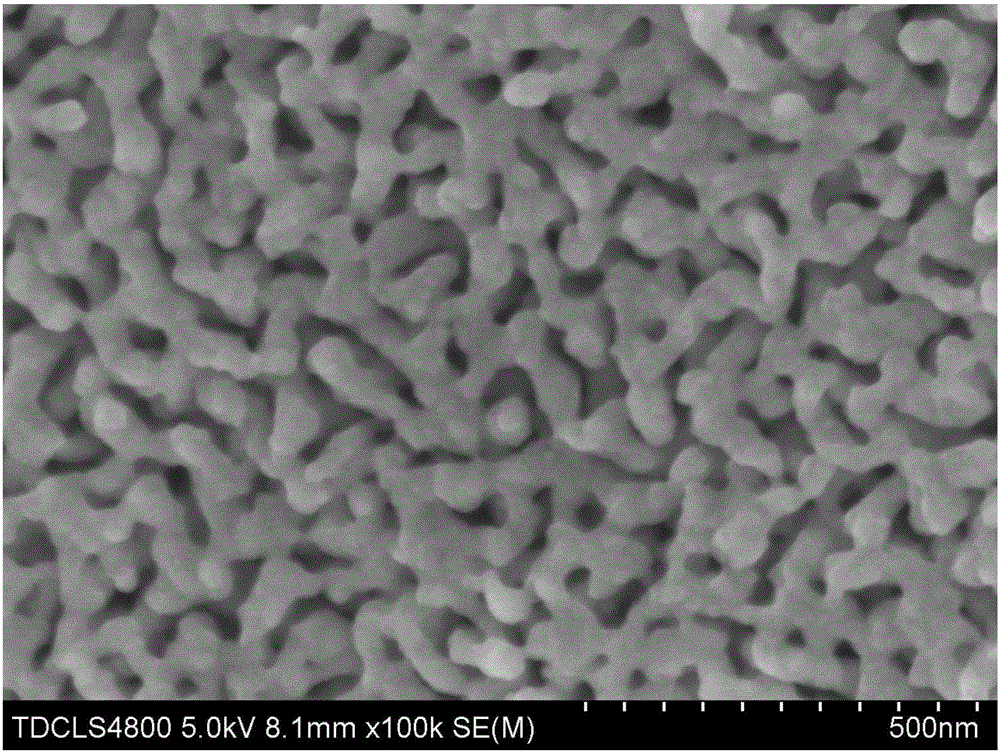

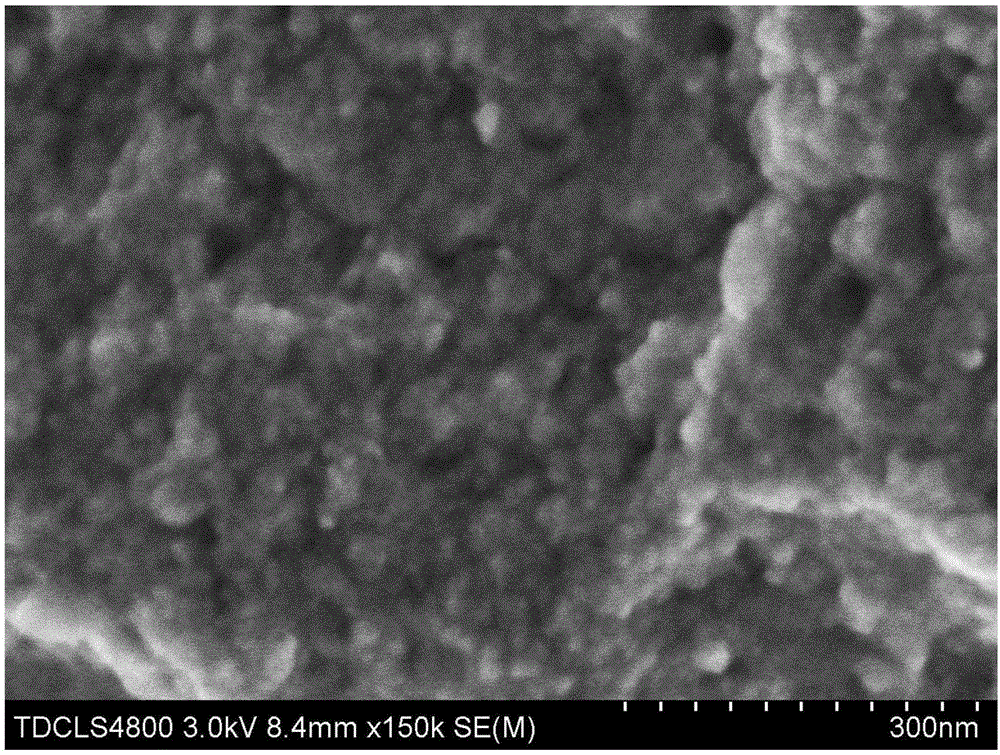

[0030] Choose Cu with a thickness of 50um 30 mn 70 Alloy foil and cut it into 1*1cm 2 size. Then configure a hydrochloric acid solution with a concentration of 0.05M, immerse the alloy foil in the hydrochloric acid solution, and carry out dealloying at room temperature. The dealloying time is 120 minutes. After dealloying, the foil is passed through deionized water-alcohol After cleaning, put it into a vacuum drying oven after cleaning, and vacuum dry at room temperature for 12 hours to obtain nanoporous copper. Put the completely dry nanoporous copper into the quartz ark, and place the ark in the outer area of the reaction tube furnace, and feed acetylene, argon and hydrogen, and the ratio of the three gases is C 2 h 2 :Ar:H 2 =5:500:200 sccm. At the same time, the temperature of the tube furnace was raised to 800°C. When the furnace temperature reached 800°C, the quartz ark was quickly moved from the outside of the furnace to the constant temperature zone in the midd...

Embodiment 2

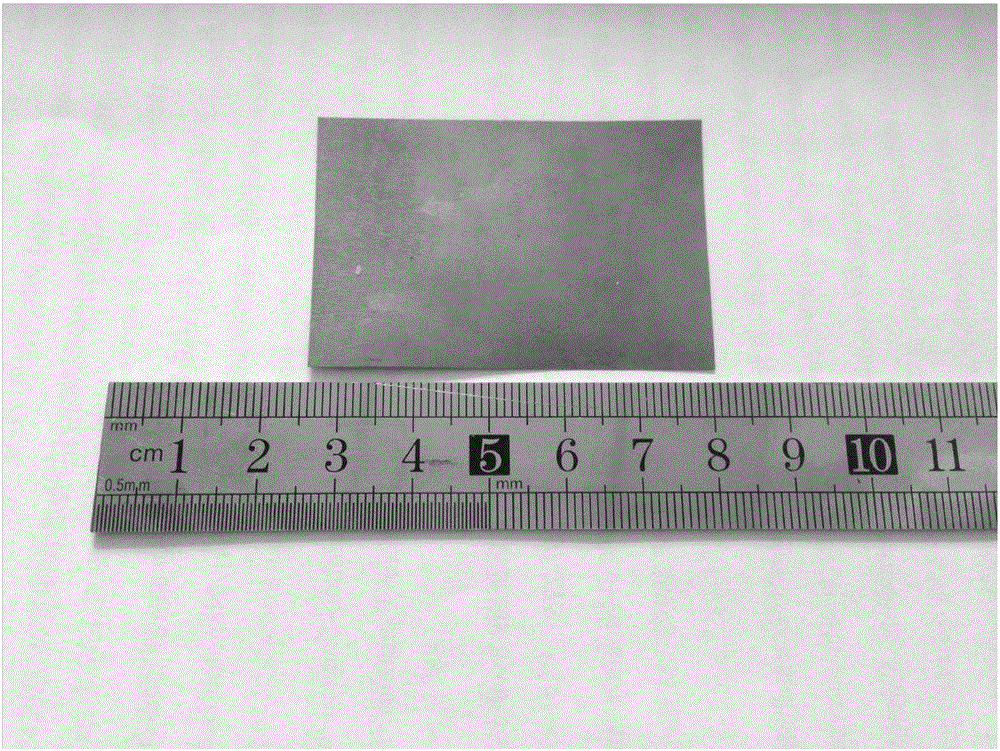

[0032] Choose Cu with a thickness of 150um 30 mn 70 Alloy foil and cut it into 1*2cm 2size. Then an ammonium sulfate solution with a concentration of 1M was prepared, and the alloy was dealloyed by a constant potential method at room temperature with a corrosion potential of -0.4V and a corrosion time of 150 minutes. After dealloying, the foils were cleaned by deionized water-alcohol in sequence, put into a vacuum drying oven after cleaning, and vacuum-dried at room temperature for 12 hours to obtain nanoporous copper. Put the completely dried nanoporous copper into the quartz ark, place the ark in the outer area of the reaction tube furnace, and feed methane, argon and hydrogen, and the ratio of the three gases is C 2 h 2 :Ar:H 2 =20:500:200 sccm. At the same time, raise the temperature of the tube furnace to 900°C. When the furnace temperature reaches 900°C, quickly move the quartz ark from the outside of the furnace to the constant temperature zone in the middle of ...

Embodiment 3

[0034] Choose Ni with a thickness of 100um 15 Cu 15 mn 70 Alloy foil, and cut it into 2*1cm 2 size. Then an ammonium sulfate solution with a concentration of 1M was prepared, and the alloy was dealloyed by a constant potential method at room temperature, with a corrosion potential of -0.5V and a corrosion time of 240 minutes. After de-alloying, the foils are cleaned by deionized water-alcohol in sequence, put into a vacuum drying oven after cleaning, and vacuum-dried at room temperature for 12 hours to obtain nanoporous nickel-copper. Put the completely dried nano-porous nickel-copper into the quartz ark, and place the ark in the outer area of the reaction tube furnace, and feed ethylene, argon and hydrogen, and the ratio of the three gases is C 2 h 4 :Ar:H 2 = 1:200:50 sccm. At the same time, raise the temperature of the tube furnace to 1000°C. When the furnace temperature reaches 1000°C, quickly move the quartz ark from the outside of the furnace to the constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com