Submicron organic spiro aluminum phosphate flame retardant and preparation method thereof

A spirocyclic aluminum phosphate, sub-micron technology, applied in the field of flame retardants, can solve the problems of long reaction time, low solubility, large product particle size, etc., and achieve good flame retardant effect, high thermal stability, and simple post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

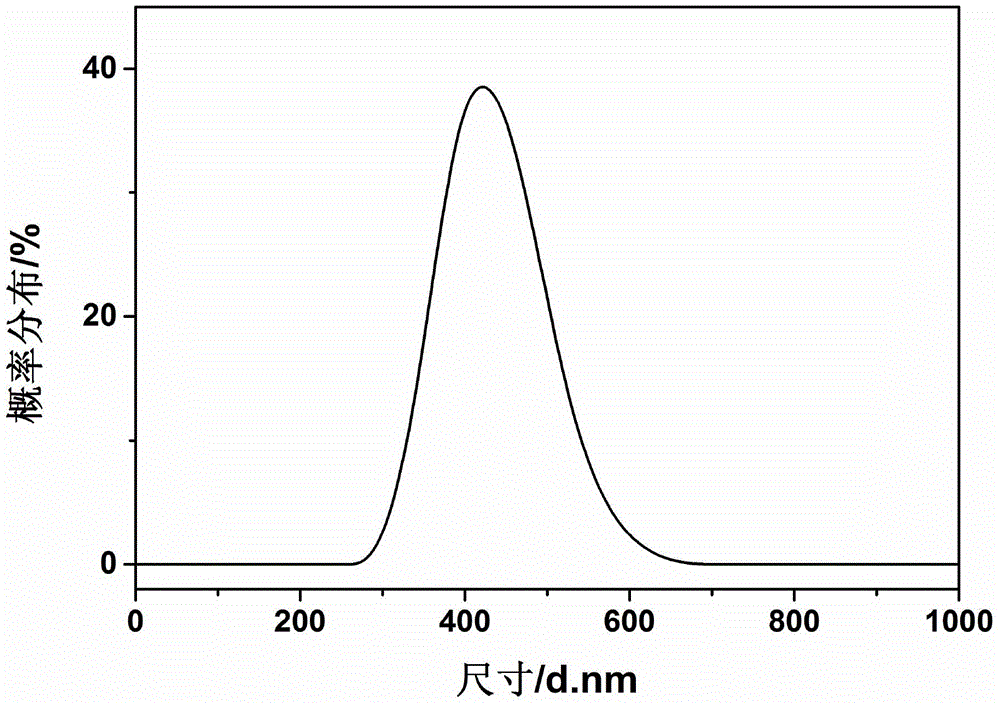

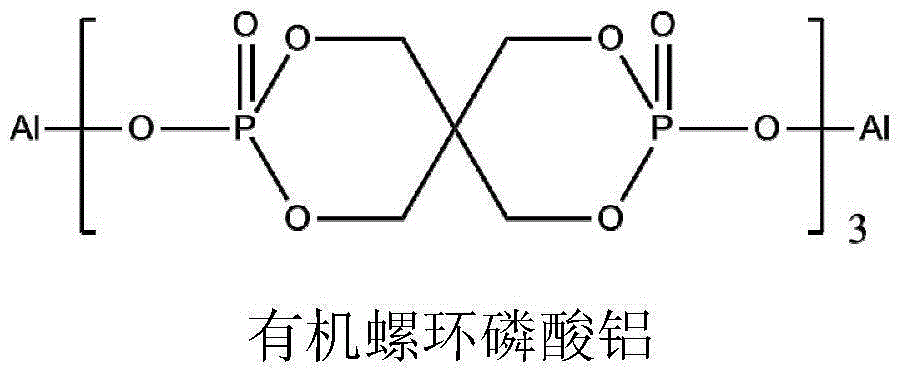

[0034] A submicron organic spirocyclic aluminum phosphate flame retardant, white powder, particle size less than 0.7μm, melting point 261-263℃, structural formula as follows:

[0035]

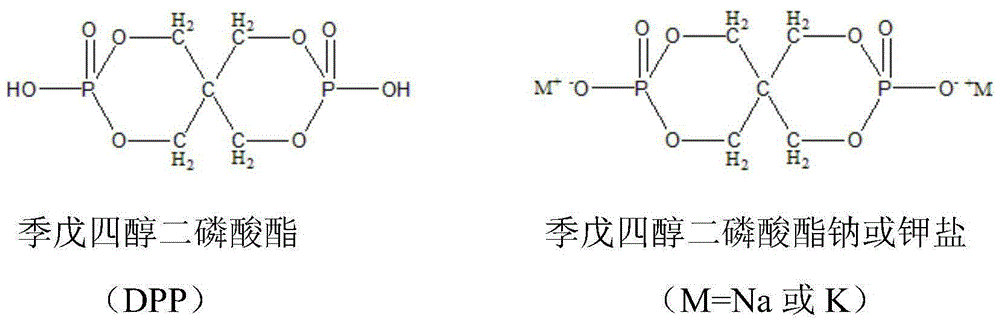

[0036] Add 1500ml of water and 300ml of alcohol-water mixed solution prepared by ethanol into the container, add 2.7g of polyvinylpyrrolidone to the above-mentioned alcohol-water mixed solution and dissolve under stirring, add 130g of DPP to the solution, dissolve under stirring, and then add alkali aqueous solution to adjust When the pH value reaches 6.7, stir and mix evenly, then add 140g of aluminum nitrate nonahydrate to the above solution, mix evenly under stirring, add an aqueous alkali solution to adjust the pH value to 6.3, stir and react at 70°C for 4 hours, cool to room temperature after the reaction, and filter , washed with water, and vacuum-dried at 80°C to obtain 131g of submicron organic spirocyclic aluminum phosphate, with a purity of 99.3%, a particle size of 457nm, and a nar...

Embodiment 2

[0038] A submicron organic spirocyclic aluminum phosphate flame retardant, white powder, particle size less than 0.7μm, melting point 261-263℃, structural formula as follows:

[0039]

[0040] Add 1200ml water and 300ml alcohol-water mixed solution prepared by methanol in the container, add 2.3g sodium dodecylbenzenesulfonate to the above-mentioned alcohol-water mixed solution and dissolve under stirring, add 104g DPP to the solution, dissolve under stirring condition, Then add an aqueous alkali solution to adjust the pH value to 6.6, stir and mix evenly, then add 72g of aluminum trichloride hexahydrate to the above solution, mix evenly under stirring, add an aqueous alkali solution to adjust the pH value to 6.5, stir and react at 60°C for 3 hours, and react After finishing, cool to room temperature, filter, wash with water, and vacuum-dry at 110° C. to obtain 106 g of submicron organospirocyclic aluminum phosphate, with a purity of 98.3% and a particle size of 503 nm.

Embodiment 3

[0042] A submicron organic spirocyclic aluminum phosphate flame retardant, white powder, particle size less than 0.7μm, melting point 261-263℃, structural formula as follows:

[0043]

[0044] Add 3000ml of water and 800ml of alcohol-water mixed solution prepared by ethanol into the container, add 8.7g of polyvinyl alcohol to the above-mentioned alcohol-water mixed solution and dissolve under stirring, add 182g of DPP to the solution, dissolve under stirring, and then add alkaline aqueous solution to adjust When the pH value reaches 6.7, stir and mix evenly, then add 171g of aluminum sulfate octadecahydrate to the above solution, mix evenly under stirring, add an aqueous alkali solution to adjust the pH value to 6.4, stir and react at 50°C for 3 hours, and cool to room temperature after the reaction is completed. Filtration, washing with water, and vacuum drying at 120° C. yielded 190 g of submicron organic spirocyclic aluminum phosphate, with a purity of 99.1% and a particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com