Preparation method and application of a kind of hydrostatic pressure-resistant flame-retardant waterborne polyurethane

A water-based polyurethane and hydrostatic pressure-resistant technology, which is applied in the field of textile chemical industry, can solve the problems of high viscosity in prepolymerization reaction, difficult to control the reaction, and affect the mechanical properties of application performance, so as to achieve good storage stability, safe cohesion, resistance good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

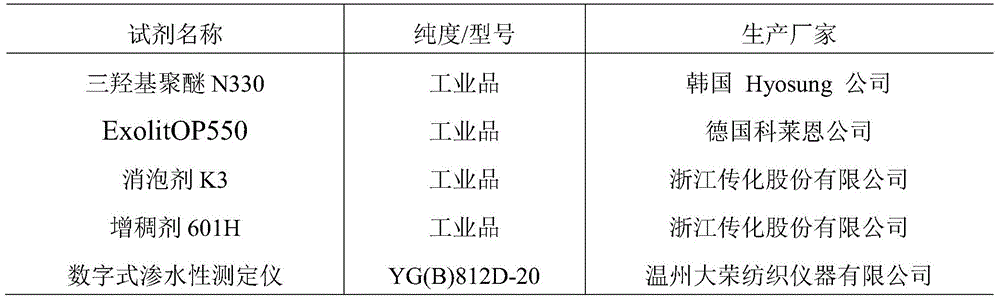

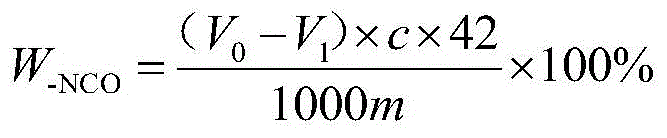

[0039] Take 21g of PTMG with a molecular weight of 2000, 4.05g of trihydroxypolyether N330 and 4.6g of dimethylol propionic acid in a four-neck flask, dehydrate under vacuum at 120°C for 1 hour, then cool down naturally to 60°C, blow nitrogen, and install condensing reflux tube, add 40g of methyl ethyl ketone, after the temperature stabilizes, add 26.25g of liquefied MDI dropwise into the constant pressure dropping funnel, control the speed, finish adding in about 0.5h, remove the nitrogen, raise the temperature to 75°C, react for about 2h, and the test shows that in the solution The -NCO content is close to the theoretical value, then add 15.1g ExolitOP550, react for about 3 hours, the test shows that the -NCO content in the solution is close to the theoretical value, then add 1g 1,4-butanediol, react for about 1 hour, the test shows that the -NCO content in the solution Close to the theoretical value, lower to room temperature, add 3.5g triethylamine to neutralize for 30s, th...

Embodiment 2

[0042] Take 33g of PTMG with a molecular weight of 2000, 6.35g of trihydroxypolyether N330 and 4.6g of dimethylol butyric acid in a four-neck flask, dehydrate under vacuum at 100°C for 1.5h, then cool down naturally to 70°C, blow nitrogen, and install condensation Add 40g of tetrahydrofuran to the reflux tube. After the temperature stabilizes, add 26.25g of MDI dropwise to the constant pressure dropping funnel, control the speed, and finish adding in about 0.5h. Remove the nitrogen, raise the temperature to 85°C, and react for about 1.5h. The test shows that the solution is The -NCO content is close to the theoretical value, then add 8.3g ExolitOP550, react for about 3 hours, the test shows that the -NCO content in the solution is close to the theoretical value, then add 1g 1,4-butanediol, react for about 0.5h, the test shows that the -NCO content in the solution Close to the theoretical value, lower to room temperature, add 3.5g of triethylamine to neutralize for 5min, add 154...

Embodiment 3

[0045] Take 33.8g of PPG with a molecular weight of 2000, 9g of trihydroxypolyether N330 and 4.6g of dimethylolpropionic acid in a four-neck flask, dehydrate under vacuum at 100°C for 1.5h, then cool down naturally to 75°C, blow nitrogen, and install condensation Add 50g of tetrahydrofuran to the reflux tube. After the temperature is stable, add 18.3g of TDI dropwise through the constant pressure dropping funnel, control the speed, and finish adding in about 0.5h. Remove the nitrogen, raise the temperature to 80°C, and react for about 2h. The test shows the -NCO content in the solution. Close to the theoretical value, then add 7.8g ExolitOP550, react for about 3.5h, the test shows that the -NCO content in the solution is close to the theoretical value, then add 1g of diethylene glycol, react for about 1h, the test shows that the -NCO content in the solution is close to the theoretical value , down to room temperature, and then add 3.5g of triethylamine for neutralization for 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com