Non-rusting silver alloy and preparation method thereof

A silver alloy, anti-tarnish technology, applied in the field of metal materials, to achieve the effect of reducing production costs, simple ingredients, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

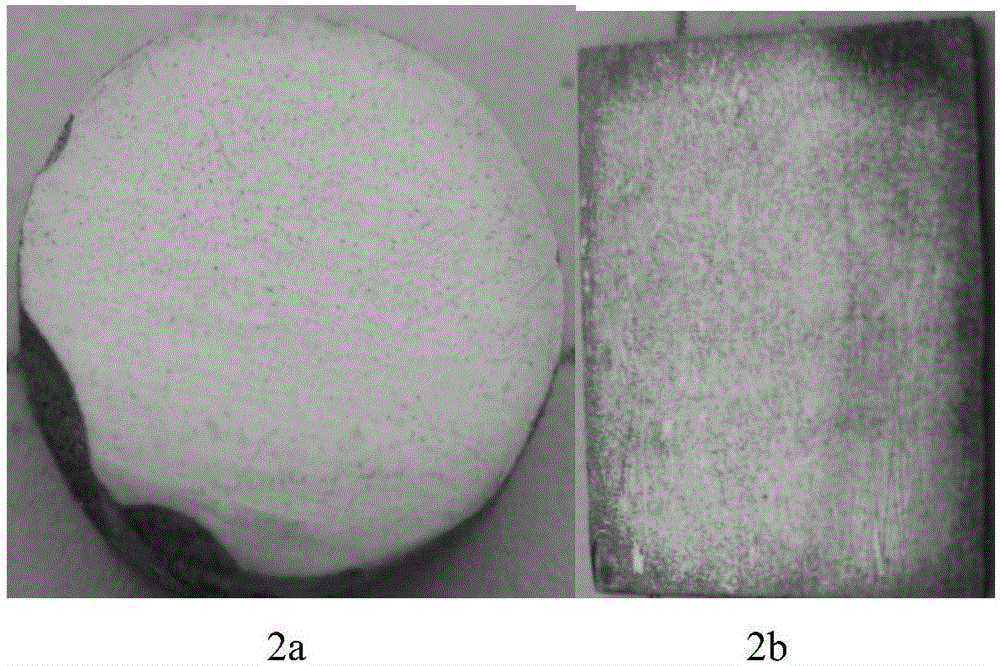

Image

Examples

Embodiment 1

[0050] The formulation of the anti-tarnish silver alloy material is as follows: silver 92.5%, copper 0.5%, zinc 0.5%, tin 0.5%, indium 1.5%, germanium 4.5%.

[0051] The components of each element are weighed and mixed according to the above ratio, and the vacuum induction melting method is used for high-frequency vacuum melting, and the vacuum degree is greater than or equal to 10 -2Pa, the melting temperature is 950-1050°C. After the alloy is completely melted, it is filled with high-purity argon as a protective atmosphere, and cast into silver alloy ingots. Then the silver alloy ingot was homogenized and heat-treated at 720° C. for 8 hours, and then cold-rolled at room temperature to make a silver alloy sheet. After the silver alloy sheet was annealed and heat-treated at 650°C for 0.5 hour, an anti-tarnish silver alloy sample 1# was prepared.

[0052] The prepared anti-tarnish silver alloy sample 1# of the present embodiment is placed in 0.1mol / lNa 2 Soak and corrode in ...

Embodiment 2

[0054] The formulation of the anti-tarnish silver alloy material is as follows: silver 92.5%, copper 3.4%, zinc 1.5%, tin 0.4%, indium 2.0%, germanium 0.2%.

[0055] Each element component is weighed and mixed according to the above ratio, and the vacuum induction melting method is used for high-frequency vacuum melting, and the vacuum degree is greater than or equal to 10 -2 Pa, the melting temperature is 950-1050°C. After the alloy is completely melted, it is filled with high-purity argon as a protective atmosphere, and cast into silver alloy ingots. Then the silver alloy ingot was homogenized and heat-treated at 720° C. for 8 hours, and then cold-rolled at room temperature to make a silver alloy sheet. After annealing the silver alloy sheet at 650° C. for 0.5 hour, an anti-tarnish silver alloy sample 2# was prepared.

[0056] The prepared anti-tarnish silver alloy sample 2# of the present embodiment is placed in 0.1mol / lNa 2 Soak and corrode in the S aqueous solution med...

Embodiment 3

[0058] The formulation of the anti-tarnish silver alloy material is as follows: silver 92.5%, copper 4.2%, zinc 0.8%, tin 0.2%, indium 2.0%, germanium 0.3%.

[0059] Each element component is weighed and mixed according to the above ratio, and the vacuum induction melting method is used for high-frequency vacuum melting, and the vacuum degree is greater than or equal to 10 -2 Pa, the melting temperature is 950-1050°C. After the alloy is completely melted, it is filled with high-purity argon as a protective atmosphere, and cast into silver alloy ingots. Then the silver alloy ingot was homogenized and heat-treated at 720° C. for 8 hours, and then cold-rolled at room temperature to make a silver alloy sheet. After annealing the silver alloy sheet at 650° C. for 0.5 hour, an anti-tarnish silver alloy sample 3# was prepared.

[0060] The prepared anti-tarnish silver alloy sample 3# of the present embodiment is placed in 0.1mol / lNa 2 Soak and corrode in the S aqueous solution med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com