Polyurethane composite solar photovoltaic module frame and preparation method thereof

A solar photovoltaic and composite material technology, applied in the field of solar photovoltaic module frame and its preparation, can solve the problems of poor fatigue resistance, low lateral strength, plastic deformation, etc., and achieve strong corrosion resistance, excellent aging resistance, and dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

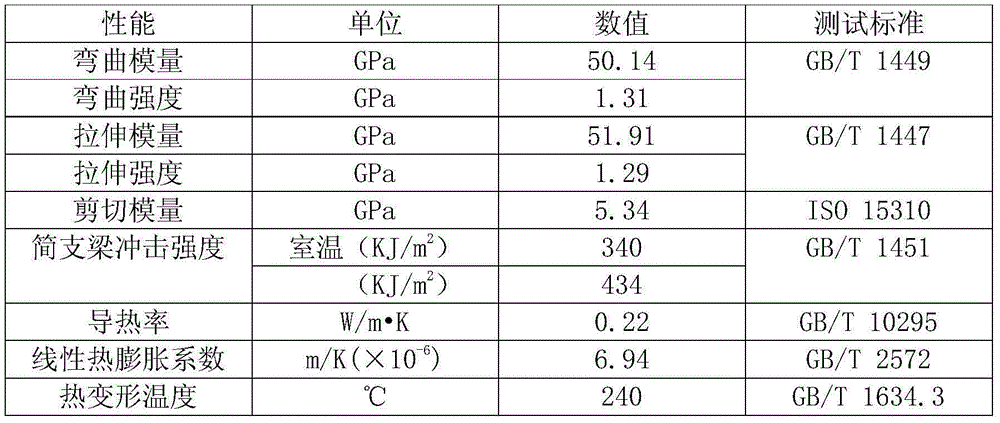

Examples

Embodiment 1

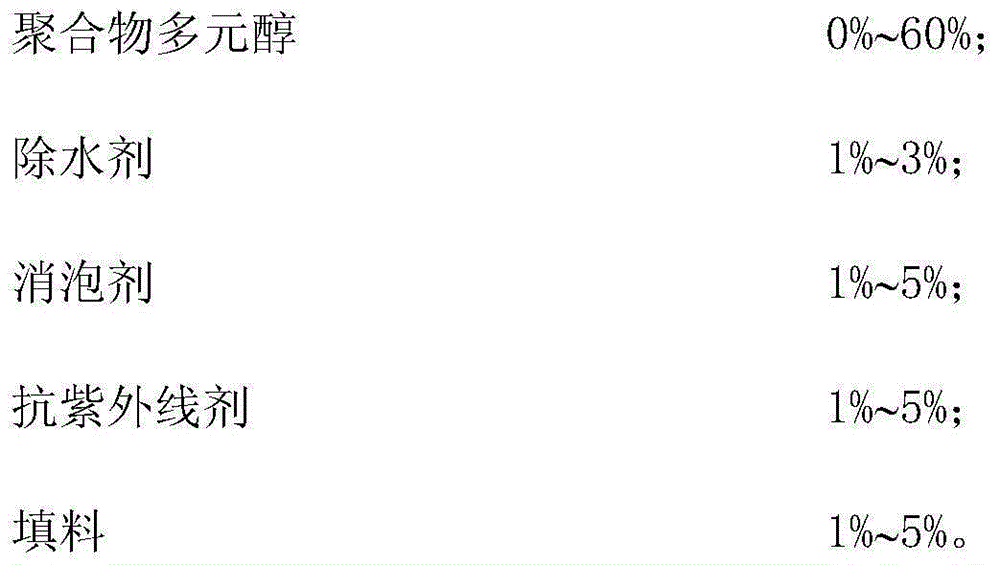

[0039] The raw material ratio of the polyurethane composite material is as follows:

[0040] Component one, isocyanate 40%;

[0041]

[0042] The mass content of glass fiber untwisted continuous roving is 60%.

[0043] The preparation method of polyurethane composite material solar photovoltaic module framework in the present embodiment is as follows:

[0044] 1) take raw materials according to the mass proportion in embodiment one;

[0045] 2) Place the isocyanate in tank one of the two-component pouring system connected to the mold head;

[0046] 3) Dewater the polymer polyol under vacuum conditions at 100°C for 1-2 hours. After cooling, add water remover, defoamer, anti-ultraviolet agent and filler, mix and stir evenly, and pour it into the head of the mold Tank two of the two-component pouring system;

[0047] 4) A certain proportion of the material in the first tank and the material in the second tank are mixed evenly and then poured into the mold;

[0048] 5) whe...

Embodiment 2

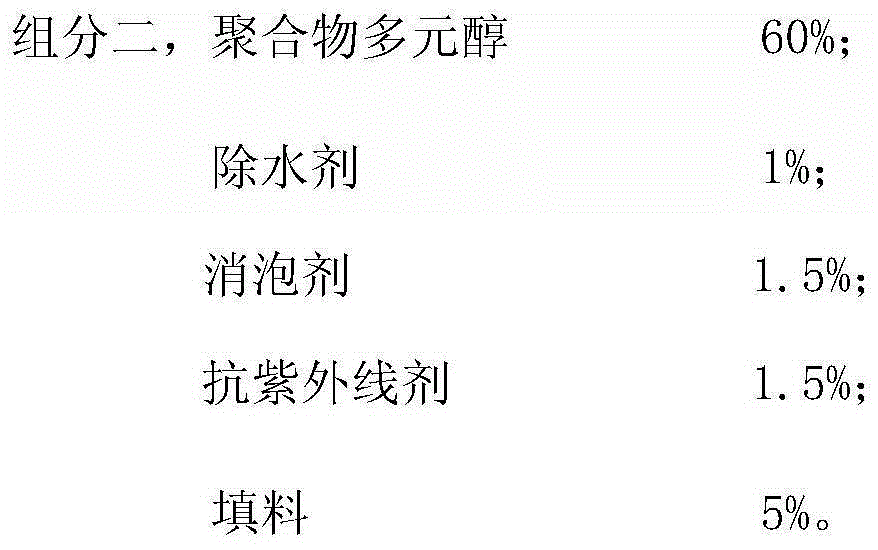

[0059] The raw material ratio of the polyurethane composite material is as follows:

[0060] Component one, isocyanate 50%;

[0061]

[0062] The mass content of glass fiber untwisted continuous roving is 70%.

[0063] The preparation method of polyurethane composite material solar photovoltaic module framework in the present embodiment is as follows:

[0064] 1) take raw materials according to the mass proportion in embodiment one;

[0065] 2) Place the isocyanate in tank one of the two-component pouring system connected to the mold head;

[0066] 3) Dewater the polymer polyol under vacuum conditions at 110°C for 1-2 hours. After cooling, add water remover, defoamer, anti-ultraviolet agent and filler, mix and stir evenly, and pour it into the mold head Tank two of the two-component gating system;

[0067] 4) A certain proportion of the material in the first tank and the material in the second tank are mixed evenly and then poured into the mold;

[0068] 5) when the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com