Glass fiber reinforced peek unidirectional tape and preparation method thereof

A technology of glass fiber and unidirectional tape, which is applied in the field of materials, can solve the problems of difficult molding process of thermoplastic resin-based composite materials, cannot be used to prepare thermoplastic resin prepregs, and high melt viscosity, etc., to achieve high production efficiency and good viscosity And the effect of spreading and stabilizing the amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take a prepreg tape with a glass fiber volume fraction of 50% as an example.

[0029] The ec8-960 alkali-free glass fiber is used as the reinforcing fiber, the PEEK resin powder with a particle size of 20 μm produced by Jilin Zhongyan is used as the matrix resin; the 0.05mm thick high-temperature-resistant polyimide film is used as the isolation film for the process.

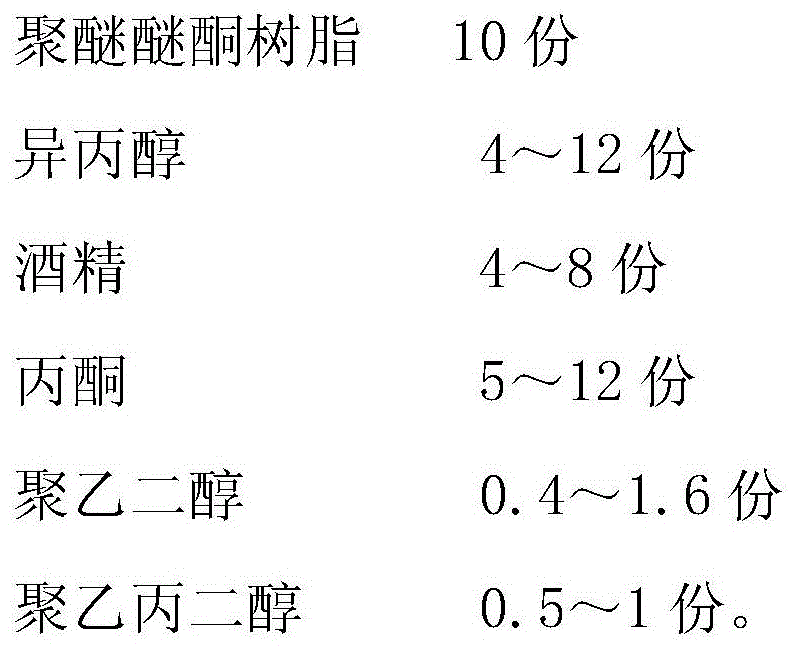

[0030] Glue preparation: Mix 12 parts of isopropanol, 6 parts of alcohol, 12 parts of acetone, 1.6 parts of polyethylene glycol with a molecular weight of 600, and 0.8 parts of polyethylene glycol with a molecular weight of 600, and add 10 parts of resin powder into the mixed solvent , Stir and mix evenly until the powder is completely soaked; add the mixed system to 75 parts of water, fully disperse, and obtain a water suspension system with a turbidity of 6.7g / L, pour it into a dipping tank, and set aside.

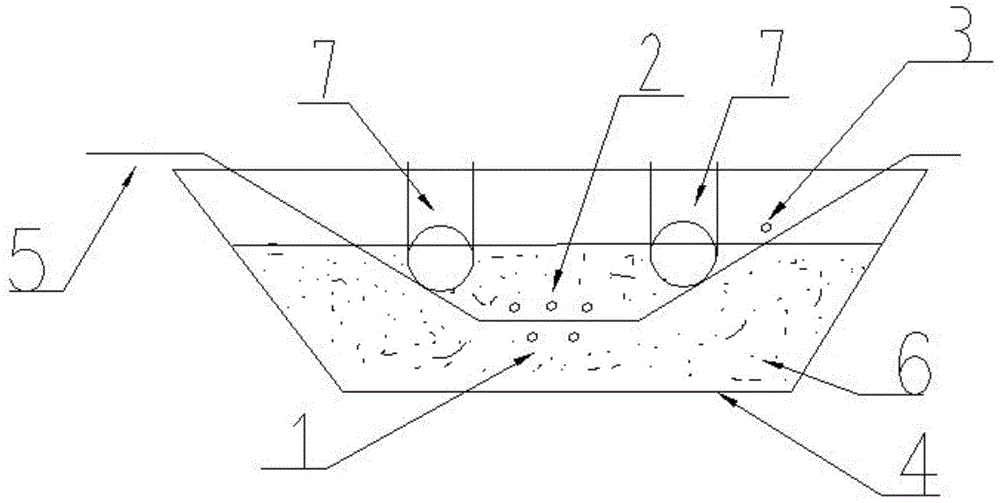

[0031] The equipment parameters are set to adjust the gaps of the three-stage press rollers of t...

Embodiment 2

[0035] Take a prepreg tape with a glass fiber volume fraction of 53% as an example.

[0036] The sc-1200 high-strength glass fiber is used as the reinforcing fiber, and the PEEK resin powder with a particle size of 20 μm produced by Jilin Zhongyan is used as the matrix resin; the 0.05mm thick high-temperature-resistant polyimide film is used as the isolation film for the process.

[0037] Glue preparation: mix 10 parts of isopropanol, 8 parts of alcohol, 5 parts of acetone, 1.2 parts of polyethylene glycol with a molecular weight of 600, and 0.6 parts of polyethylene glycol with a molecular weight of 400, and add 10 parts of resin powder into the mixed solvent , Stir and mix evenly until the powder is completely infiltrated; add the mixed system to 95 parts of water, fully disperse to obtain a water suspension system with a turbidity of 5.9g / L, pour it into a dipping tank, and set aside.

[0038] The equipment parameters are set to adjust the gaps of the three-stage press roll...

Embodiment 3

[0042] Take a prepreg tape with a glass fiber volume fraction of 56% as an example.

[0043] The ec8-960 alkali-free glass fiber is used as the reinforcing fiber, the PEEK resin powder with a particle size of 20 μm produced by Jilin Zhongyan is used as the matrix resin; the 0.05mm thick high-temperature-resistant polyimide film is used as the isolation film for the process.

[0044]Glue preparation: Mix 6 parts of isopropanol, 5 parts of alcohol, 9 parts of acetone, 0.8 parts of polyethylene glycol with a molecular weight of 400, and 1 part of polyethylene glycol with a molecular weight of 600, and add 10 parts of resin powder to the mixed solvent , Stir and mix evenly until the powder is completely infiltrated; add the mixed system to 110 parts of water, fully disperse, and obtain a water suspension system with a turbidity of 5.1g / L, pour it into a dipping tank, and set aside.

[0045] The equipment parameters are set to adjust the gaps of the three-stage press rollers of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com