Forming method of thick-wall winding square pipe

A forming method and wet winding technology, which is applied in the forming field of thick-walled winding square tubes, can solve problems such as rounding and rubber content, and achieve the effects of reducing processing costs, reducing operation difficulty, and reducing local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

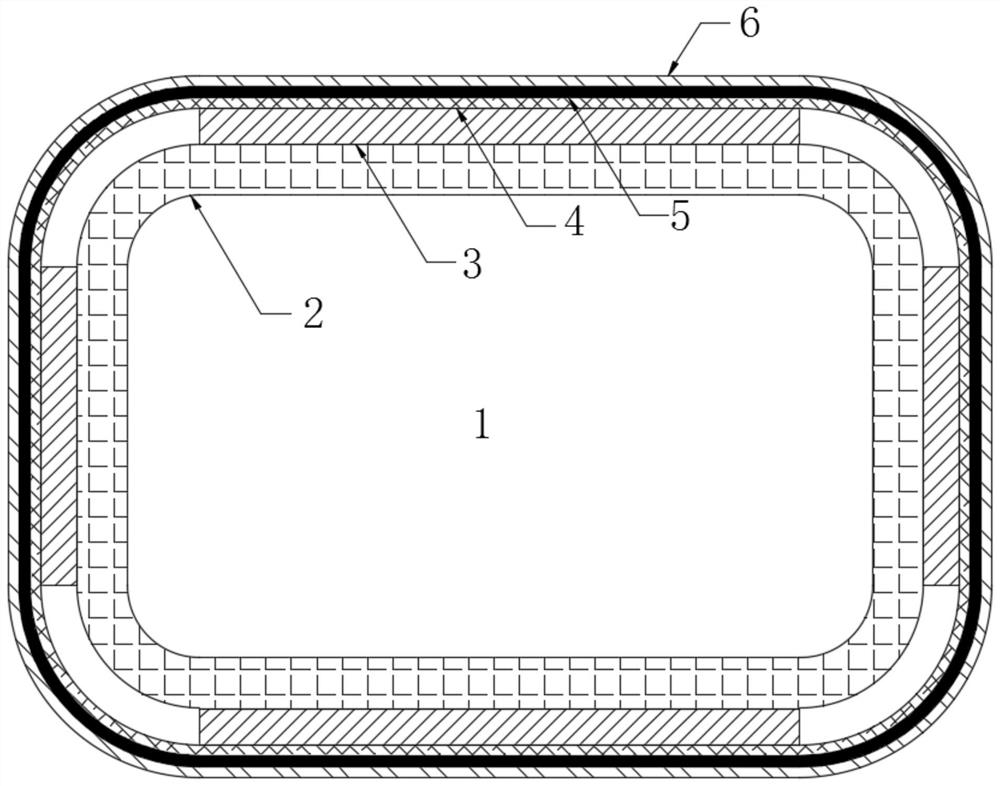

[0021] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention is clearly and completely elaborated. It should be noted that, without conflict, the embodiments of the present invention and the features in the embodiments may be combined with each other, and the embodiments described are only part of the embodiments of the present invention, not all embodiments.

[0022] See Figure 1 Description of the present embodiment, a thick-walled winding square tube forming method, which comprises the following steps:

[0023] Step 1: Follow the wet winding process to wind the fibers around the mold 1 to form an uncured wound product 2;

[0024] Step 2: After the wet winding molding is completed, lay the equalizing plate 3 on the four planes on the outside of the uncured winding product 2, so that the equalizing plate 3 and the winding product 2 surface paste are combined and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com