Preparation method of high-temperature-resistant thermoplastic composite unidirectional prepreg tape

A unidirectional prepreg tape, composite material technology, applied in the direction of coating, etc., can solve the problem of not providing solvent treatment, winding, solvent environment pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

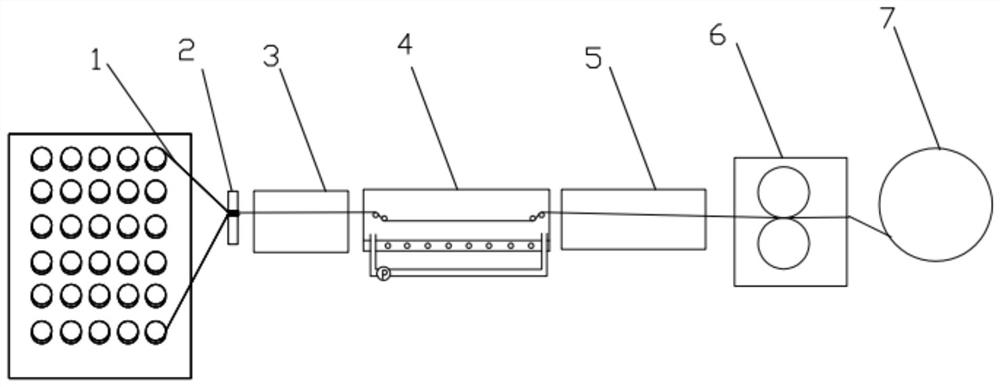

Method used

Image

Examples

Embodiment 1

[0033] T-700 carbon fiber is used as reinforcing fiber, thermoplastic polyimide resin with a glass transition temperature Tg of 350°C developed by Changchun Yinghua Institute of Chinese Academy of Sciences is used as matrix resin, DMAc is used as solvent, and water is used as precipitant. The equipment parameters are set as: yarn feeding tension 2kg, winding tension 2kg, running speed 2.5m / min.

[0034] Specific steps are as follows:

[0035] 1) Configure the resin solution:

[0036] Weigh 2 kg of resin, put it into a flask, add 6 kg of solvent, and dissolve at room temperature to obtain a resin solution with a solid content of 25%, and add it to the dipping tank 3;

[0037] 2) Fiber impregnation: the fiber 1 enters the dipping tank 3 after being spread by the spreading rod 2, and the fiber 1 is fully impregnated in the dipping tank 3;

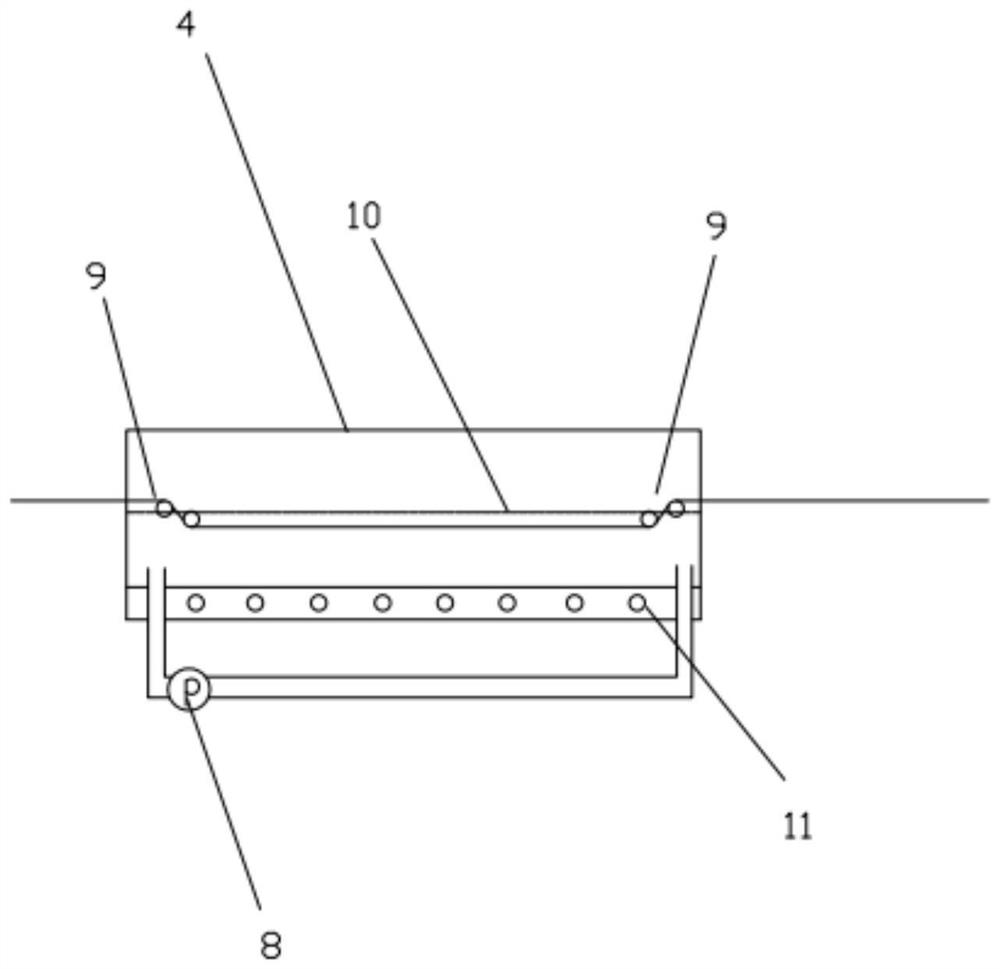

[0038] 3) Precipitation: Weigh 60kg of water, add it to the precipitation tank 4, import the unidirectional prepreg tape obtained in step 2...

Embodiment 2

[0043] T-700 carbon fiber is used as the reinforcing fiber, the thermoplastic polyimide resin with a Tg of 350°C developed by the Changchun Applied Chemical Institute of the Chinese Academy of Sciences is used as the matrix resin, and the solvent is a mixed solvent of DMF and DMAc (the mass ratio of DMF and DMAc = 1:1) , water is the precipitation agent. The equipment parameters are set as: yarn feeding tension 2kg, winding tension 2kg, running speed 1.5m / min.

[0044] Specific steps are as follows:

[0045] 1) Configure the resin solution:

[0046] Weigh 2 kg of resin, put it into a flask, add 8 kg of solvent, and dissolve at room temperature to obtain a resin solution with a solid content of 20%, and add it to the dipping tank 3;

[0047] 2) Fiber impregnation: the fiber 1 enters the dipping tank 3 after being spread by the spreading rod 2, and the fiber 1 is fully impregnated in the dipping tank 3;

[0048] 3) Precipitation: Weigh 60kg of water, add it to the precipitati...

Embodiment 3

[0053] T-700 carbon fiber is used as reinforcing fiber, polyarylether sulfone ketone (PPESK) resin with a Tg of 260°C is used as matrix resin, NMP is used as solvent, and water is used as precipitant. The equipment parameters are set as: yarn feeding tension 2kg, winding tension 2kg, running speed 2m / min.

[0054] Specific steps are as follows:

[0055] 1) Configure the resin solution:

[0056] Weigh 1.4kg of resin, put it into a flask, add 2.6kg of solvent, and dissolve at 60-80°C to obtain a resin solution with a solid content of 35%, and add it to dipping tank 3;

[0057] 2) Fiber impregnation: the fiber 1 enters the dipping tank 3 after being spread by the spreading rod 2, and the fiber 1 is fully impregnated in the dipping tank 3;

[0058] 3) Precipitation: Weigh 60kg of water, add it to the precipitation tank 4, import the unidirectional prepreg tape obtained in step 2) into the precipitation tank 4, set the water temperature in the precipitation tank 4 to 40-60°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com