Catalyst for preparing benzaldehyde by direct oxidation of toluene and preparation method thereof

A catalyst and benzaldehyde technology, applied in the field of industrial catalysis, can solve the problems of uneconomical industrial production, high reaction temperature, and difficult product separation, and achieve the effects of easy separation and purification, mild reaction conditions, and enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

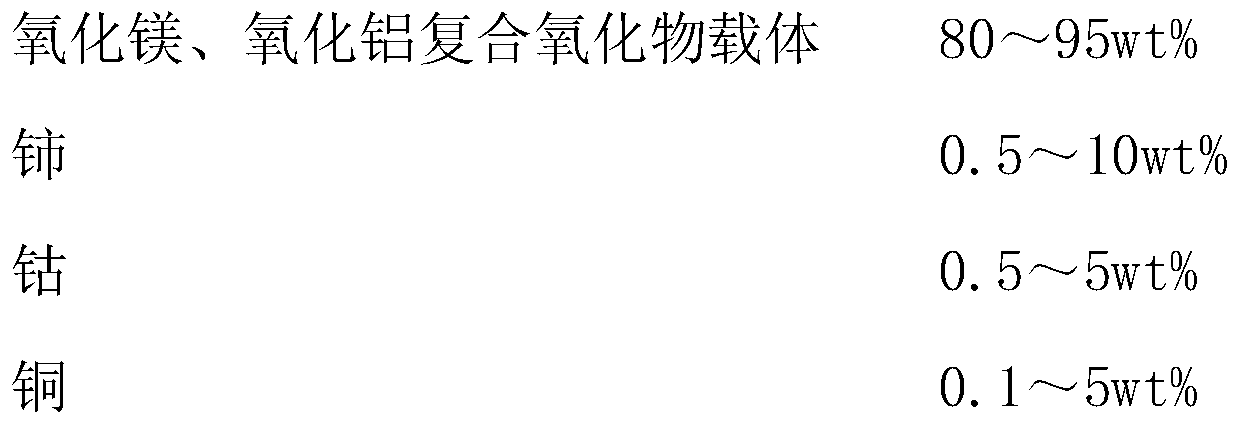

[0023] A catalyst for the direct oxidation of toluene to produce benzaldehyde, comprising the following components: 80wt% magnesia-alumina composite oxide carrier, wherein the molar ratio of magnesia to alumina is 1, cerium 10wt%, cobalt 3wt%, copper 5wt% , Nickel 2wt%.

[0024] The preparation method of above-mentioned catalyst comprises the steps:

[0025] 1) Weigh 150g Al(NO 3 ) 3 9H 2 O and 51.3g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 1200 mL of deionized water to make a total concentration of 0.5 mol L -1 Mixed salt solution, weigh 80g NaOH and dissolve in 400ml deionized water to prepare 5mol L -1 Add the NaOH solution drop by drop to the mixed salt solution under stirring conditions, keep the pH value of the system at 9-10 during the dropwise addition, continue stirring and aging for 3 hours after the NaOH solution is added dropwise, and the obtained product Filter, wash with deionized water repeatedly 3 times, place in a constant temperature drying oven at 100°C ...

Embodiment 2

[0029] A catalyst for the direct oxidation of toluene to produce benzaldehyde, comprising the following components: 90wt% magnesia-alumina composite oxide carrier, wherein the molar ratio of magnesia to alumina is 1, cerium 4wt%, cobalt 5wt%, copper 0.5wt% %, nickel 0.5wt%.

[0030] The preparation method of above-mentioned catalyst comprises the steps:

[0031] 1) Weigh 150g Al(NO 3 ) 3 9H 2 O and 51.3gMg(NO 3 ) 2 ·6H 2 O was dissolved in 1200 mL of deionized water to make a total concentration of 0.5 mol L -1 Mixed salt solution, weigh 80g NaOH and dissolve in 400ml deionized water to prepare 5mol L -1 Add the NaOH solution drop by drop to the mixed salt solution under stirring conditions, keep the pH value of the system at 9-10 during the dropwise addition, continue stirring and aging for 3 hours after the NaOH solution is added dropwise, and the obtained product Filter, wash with deionized water repeatedly 3 times, place in a constant temperature drying oven at 100...

Embodiment 3

[0035] A catalyst for direct oxidation of toluene to produce benzaldehyde, comprising the following components: 85wt% magnesia-alumina composite oxide carrier, wherein the molar ratio of magnesia to alumina is 2, cerium 6wt%, cobalt 5wt%, copper 3wt% , Nickel 1wt%.

[0036] The preparation method of above-mentioned catalyst comprises the steps:

[0037] 1) Weigh 39.9g AlCl 3 and 28.8g MgCl 2 Dissolve in 1200mL deionized water to make a total concentration of 0.5mol L -1 Mixed salt solution, weigh 80g NaOH and dissolve in 400ml deionized water to prepare 5mol L -1 Add the NaOH solution drop by drop to the mixed salt solution under stirring conditions, keep the pH value of the system at 9-10 during the dropwise addition, continue stirring and aging for 3 hours after the NaOH solution is added dropwise, and the obtained product Filter, wash with deionized water repeatedly 3 times, place in a constant temperature drying oven at 100°C and dry, after drying, grind and place in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com