A method for preparing metal aluminum and its alloys by molten salt electrodeposition

An electrodeposition method, a technology of metal aluminum, applied in the field of metallurgy, can solve the problems of high cost and expensive, and achieve the effect of fast electrolysis, high conductivity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for preparing aluminum metal by molten salt electrodeposition is carried out according to the following process steps:

[0033] (1) Preparation of molten salt electrolyte: slowly mix vacuum-dried anhydrous urea and anhydrous aluminum chloride at room temperature at a molar ratio of 1:1.2, and control the stirring speed to 400r / min to form a uniform molten salt electrolysis liquid;

[0034](2) Preparation of metal aluminum by electrodeposition: Copper sheet is used as cathode, graphite is used as anode, electrolysis temperature is controlled at 40°C, constant potential method is adopted, and potential is controlled at -0.15V, electrolysis in molten salt electrolyte in step (1) Deposition 1h;

[0035] (3) After the electrolysis, the copper sheet was taken out, washed with acetone and water to obtain metal aluminum deposited on the surface, and the yield was 99.04%.

Embodiment 2

[0037] The method for preparing aluminum metal by molten salt electrodeposition is carried out according to the following process steps:

[0038] (1) Preparation of molten salt electrolyte: slowly mix vacuum-dried anhydrous acetamide and anhydrous aluminum chloride at room temperature at a molar ratio of 1:1.3, and control the stirring speed to 600r / min to form a uniform molten salt electrolyte;

[0039] (2) Preparation of metal aluminum by electrodeposition: use stainless steel sheet as the cathode, graphite as the anode, control the electrolysis temperature to 50°C, adopt the constant potential method, control the potential to -0.20V, and electrolytically electrolyze the molten salt electrolyte in step (1). Deposition 2h;

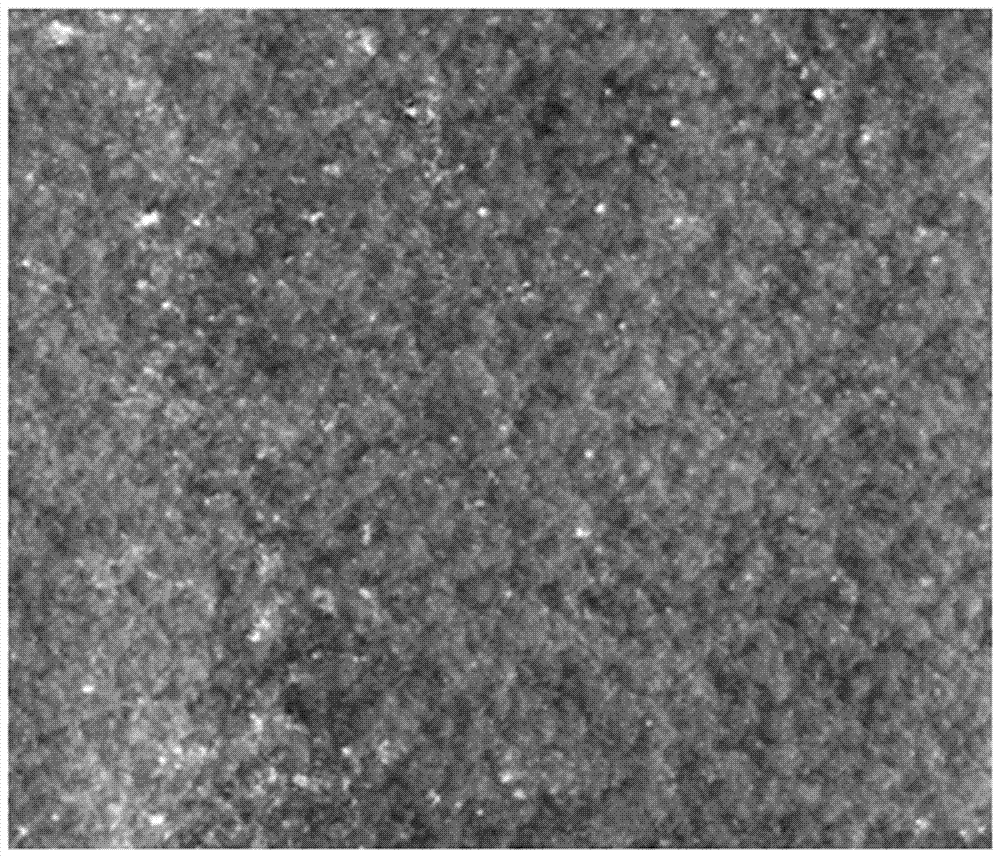

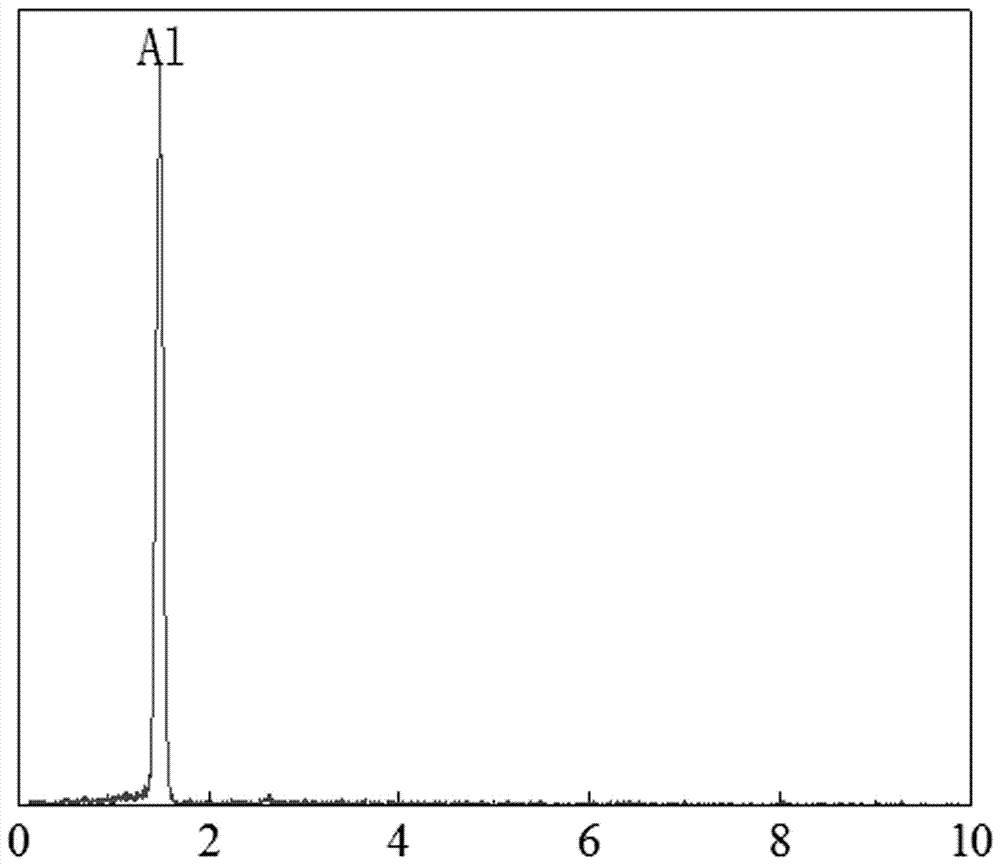

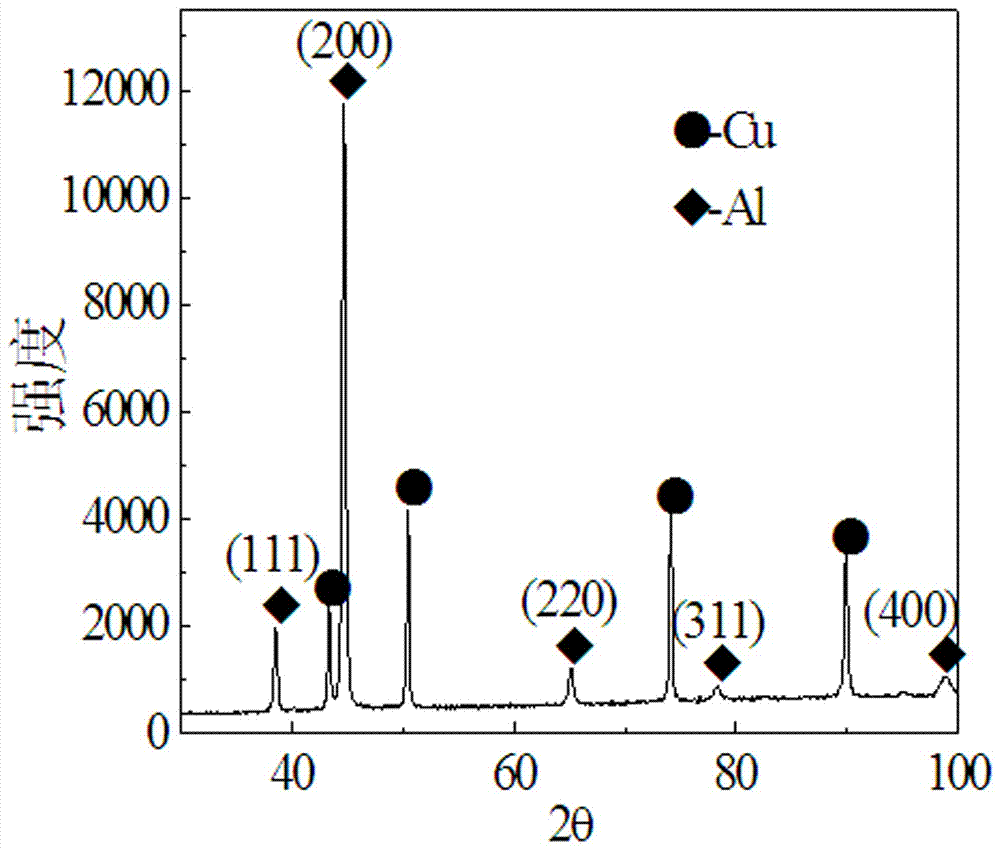

[0040] (3) After the electrolysis, the stainless steel sheet was taken out, washed with acetone and water to obtain metal aluminum deposited on its surface, and the yield was 99.02%. figure 1 , 2 , 3 show the SEM, EDS and XRD images of the prepared met...

Embodiment 3

[0042] The method for preparing aluminum metal by molten salt electrodeposition is carried out according to the following process steps:

[0043] (1) Preparation of molten salt electrolyte: slowly mix vacuum-dried anhydrous formamide and anhydrous aluminum chloride at room temperature at a molar ratio of 1:1.4, and control the stirring speed to 800r / min to form a uniform molten salt electrolyte;

[0044] (2) Preparation of metal aluminum by electrodeposition: use copper sheet as the cathode, carbon as the anode, control the electrolysis temperature at 60°C, adopt a constant potential method, and control the potential at -0.25V, in the molten salt electrolyte in step (1) Electrodeposition 3h;

[0045] (3) After the electrolysis, the copper sheet was taken out, washed with acetone and water to obtain metal aluminum deposited on its surface, and the yield was 99.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com