Secondary lithium battery and positive electrode material thereof, and positive electrode material preparation method

A technology for secondary lithium batteries and positive electrode materials, which is applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of difficulty in forming a complete and dense coating layer, inability to protect the main material, and easy pulverization of materials. Achieve the effect of high lithium ion conductivity and structural stability, excellent cycle performance and safety performance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

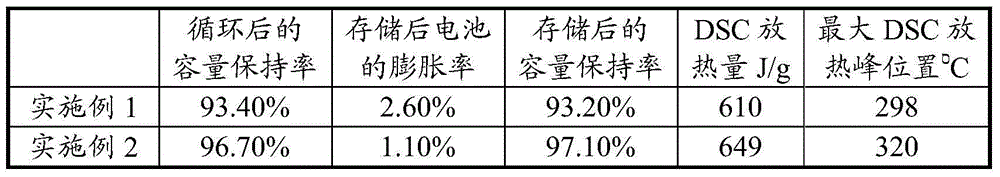

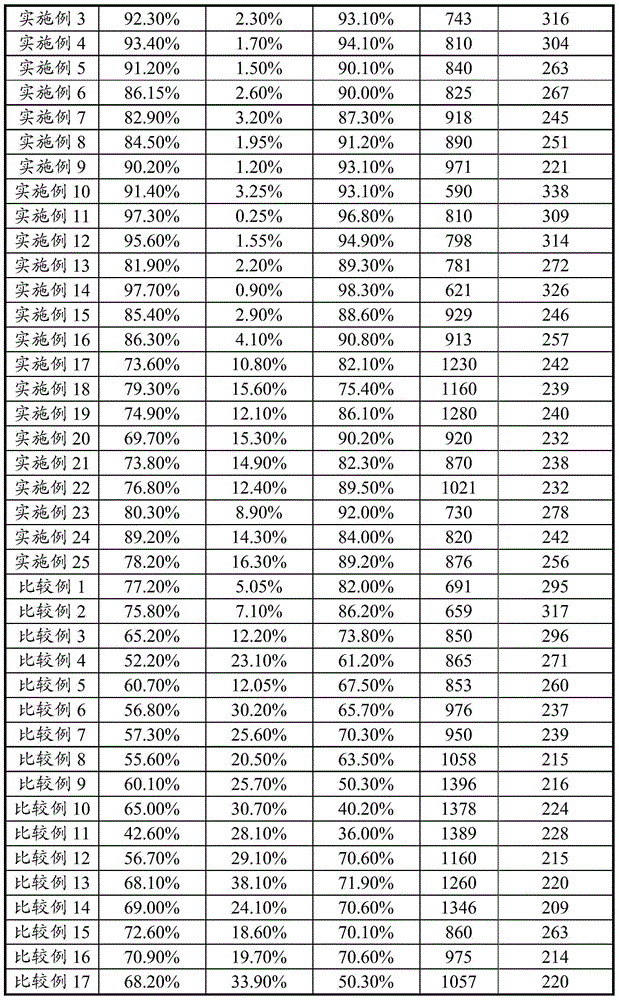

Examples

Embodiment 1

[0033] The host material of the cathode material prepared in this example is Li 1.09 Ni 0.1 co 0.5 mn 0.4 o 2 , whose cladding material is Li 1.09 Ni 0.1 co 0.5 mn 0.4 PO 4 . Among them, the main material Li 1.09 Ni 0.1 co 0.5 mn 0.4 o 2 Synthesized by co-precipitation method, the average particle size of secondary particles is 18-20μm (the average particle size of primary particles is 0.7-1.0μm), and 0.5wt% Li is coated on its surface 1.09 Ni 0.1 co 0.5 mn 0.4 PO 4 , the thickness of the cladding layer is 100-200nm. Concrete preparation steps are:

[0034] First, the NiSO 4 、CoSO 4 , MnSO 4 Dissolve in deionized water according to the metal atomic ratio of 0.1:0.5:0.4, and prepare a mixed solution with a total concentration of 1mol / L; then add the prepared 1mol / L NaOH solution to the above solution, stir while adding, and the temperature Control at 75°C; after full reaction, a coprecipitate of evacuated secondary spherical particles is formed, with an a...

Embodiment 2

[0037] The host material of the cathode material prepared in this example is Li 1.10 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 , whose cladding material Li 1.10 Ni 1 / 3 co 1 / 3 mn 1 / 3 PO 4 . Among them, the main material Li 1.10 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 Synthesized by co-precipitation method, the average particle size of the secondary particles is 48-50 μm (the average particle size of the primary particles is 4.3-5.0 μm), and the surface is coated with 0.01wt% Li 1.10 Ni 1 / 3 co 1 / 3 mn 1 / 3 PO 4 , the coating thickness is 100-500nm. Its concrete preparation steps are:

[0038] First, the NiSO 4 、CoSO 4 , MnSO 4 Dissolve in deionized water according to the atomic ratio of 1.0:1.0:1.0, and prepare a mixed solution with a total concentration of 1mol / L; then add the prepared 1mol / L NaOH solution to the above solution, stir while adding, and control the temperature At 75°C; after full reaction, evacuated secondary spherical particle co-precipitates are formed, with an average pa...

Embodiment 3

[0041] The host material of the cathode material prepared in this example is Li 1.08 Ni 0.5 co 0.2 mn 0.3 o 2 , whose cladding material Li 1.08 Ni 0.5 co 0.2 mn 0.3 PO 4 . Among them, the main material Li 1.08 Ni 0.5 co 0.2 mn 0.3 o 2 Synthesized by a combustion method, the average particle size of the secondary particles is 0.5-0.8 μm (the average particle size of the primary particles is 0.01 μm), and 20.0wt% Li is coated on its surface 1.08 Ni 0.5 co 0.2 mn 0.3 PO 4 , the thickness of the cladding layer is 50-80nm. Its concrete preparation steps are:

[0042] First, dissolve lithium nitrate, nickel nitrate, cobalt nitrate, and manganese nitrate in ethanol at an atomic ratio of 1.10:0.50:0.20:0.30; after all substances are completely dissolved, add glycerol, the ratio of glycerol to total metal ions 3:1; put the above solution into a water bath at 80°C and stir to evaporate the ethanol; when the ethanol is completely evaporated, transfer the container to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com