Method for preparing kaolin intercalation compound

A technology of intercalation compound and kaolin, which is applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of easy methanol release, long reaction cycle, unstable kaolin/methanol intercalation complex, etc., to achieve The effect of high intercalation rate and short preparation process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation process of kaolin intercalation compound of the present invention is as follows:

[0029] According to the ratio of monochloroacetic acid to 1-methylimidazole molar ratio of 1:1, put monochloroacetic acid to melt at 70-80°C, add 1-methylimidazole and react for 4-6 hours to obtain a reddish-brown viscous liquid ; Wash with absolute ethanol until the lower layer is a white solid and the upper layer is a colorless transparent liquid, the white solid is taken out and dried to obtain an ionic liquid 1-carboxymethyl-3-methylimidazolium chloride salt; set aside.

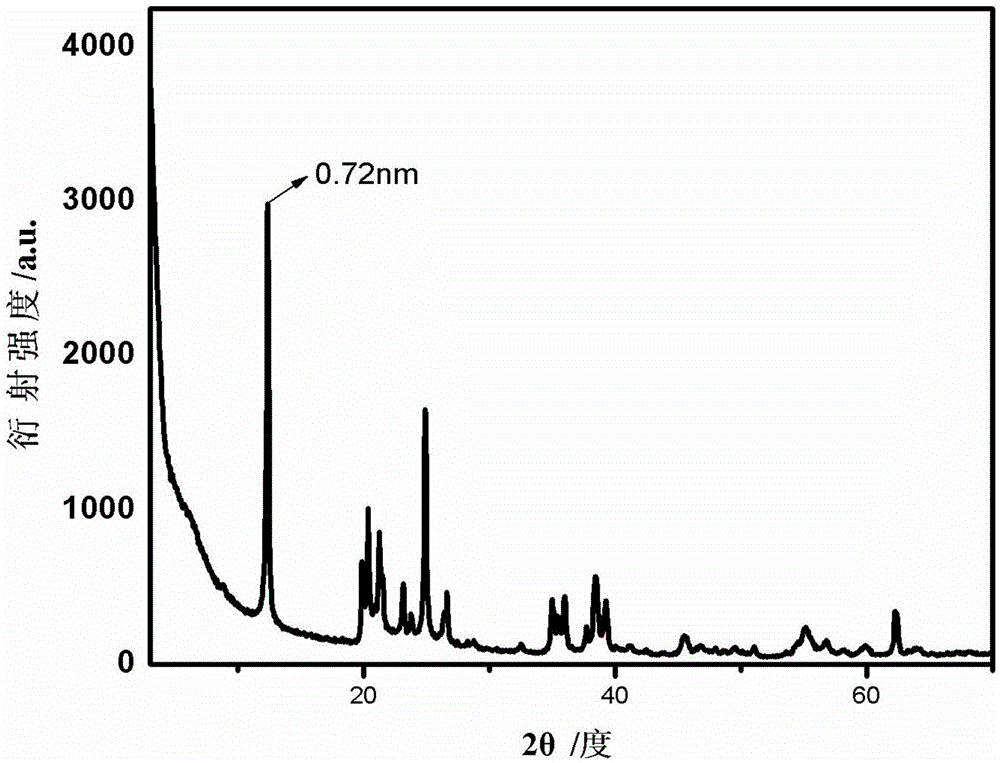

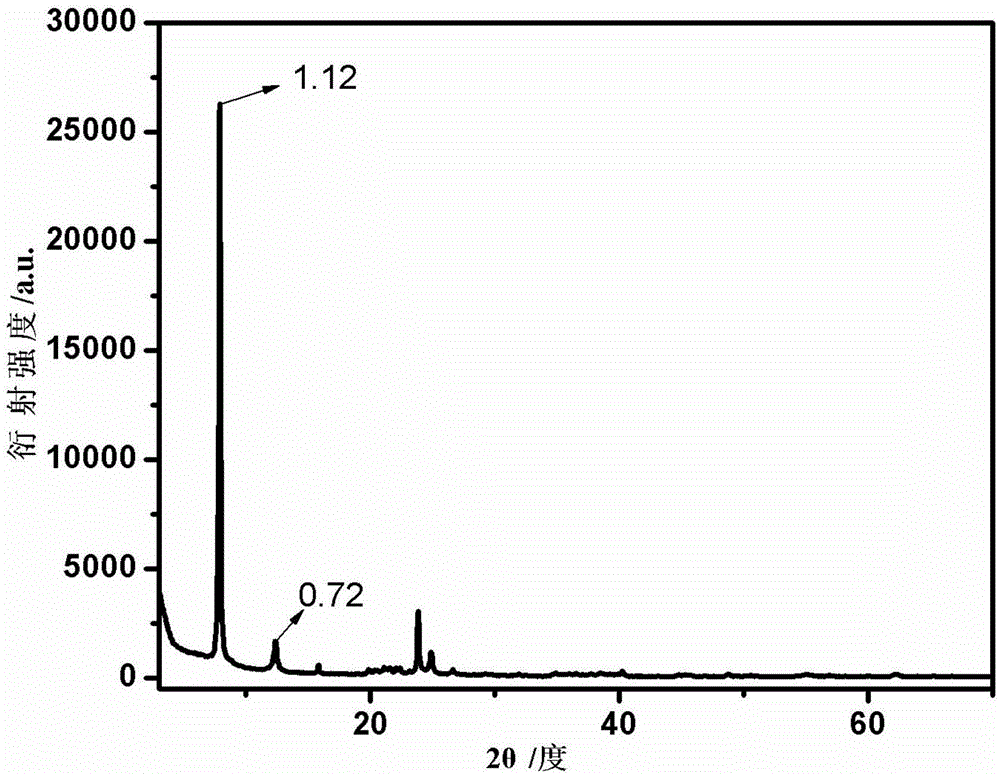

[0030] Mix kaolin: dimethyl sulfoxide: distilled water according to 15g: 60-80mL: 5-15mL, heat and stir at 25-75°C for 48-72 hours; centrifuge, wash and dry to obtain kaolin / dimethyl sulfoxide-based intercalation complex; the interlayer distance d(001) increases from 0.72nm to 1.12nm, and the intercalation rate is about 92%. It is ready for use.

[0031] The X-ray powder crystal diffraction pattern o...

Embodiment 1

[0033] Weigh 0.5 g of the spare kaolin / dimethyl sulfoxide intercalation complex and mix with 1 g of 1-carboxymethyl-3-methylimidazolium chloride salt, grind and mix with a mortar.

[0034] The ground mixture was placed in an autoclave, protected by nitrogen gas, and heated in a 210°C drying oven for 4 hours.

[0035] The reaction product was washed repeatedly with dimethyl sulfoxide to remove the residue of 1-carboxymethyl-3-methylimidazolium chloride salt, and then washed with absolute ethanol for 3-4 times and centrifuged.

[0036] The obtained reaction product was dried in a vacuum oven at 80°C.

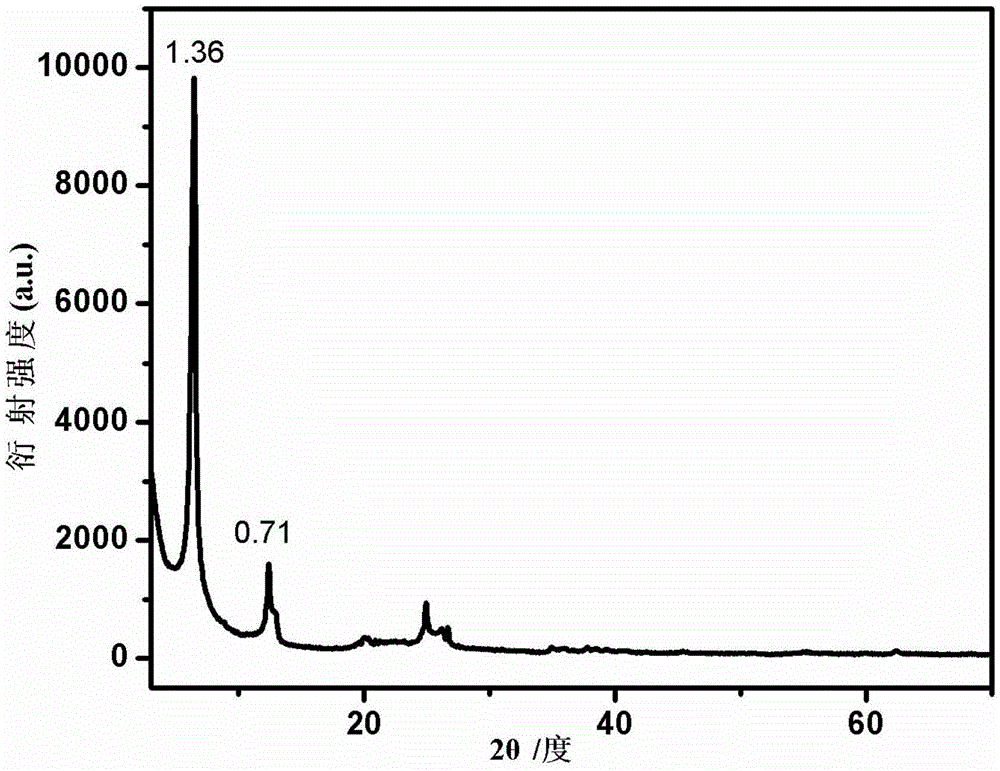

[0037] The X-ray powder crystal diffraction pattern of kaolin / 1-carboxymethyl-3 methylimidazolium chloride salt intercalation complex in the present embodiment is as follows image 3 , it can be seen from the figure that the interlayer spacing of kaolin increases from 0.71nm to 1.36nm, and the diffraction peak intensity of the intercalation complex is relatively strong, indicatin...

Embodiment 2

[0039] Weigh 0.5 g of the spare kaolin / dimethyl sulfoxide intercalation complex and mix with 1.5 g of 1-carboxymethyl-3-methylimidazolium chloride salt, grind and mix with a mortar.

[0040] The ground mixture was placed in an autoclave, protected by nitrogen gas, and heated in a 210°C drying oven for 4 hours.

[0041] The reaction product was washed repeatedly with dimethyl sulfoxide to remove the residue of 1-carboxymethyl-3-methylimidazolium chloride salt, and then washed with absolute ethanol for 3-4 times and centrifuged.

[0042] The obtained reaction product was dried in a vacuum oven at 80°C.

[0043]The X-ray powder crystal diffraction pattern of the present embodiment kaolin / 1-carboxymethyl-3 methylimidazolium chloride salt intercalation complex is as follows Figure 4 , the (001) interlayer spacing is 1.35nm, and the intercalation rate reaches 84.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com