Method for reducing granularity of kaolin fine powder

A technology of kaolin and fine powder, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

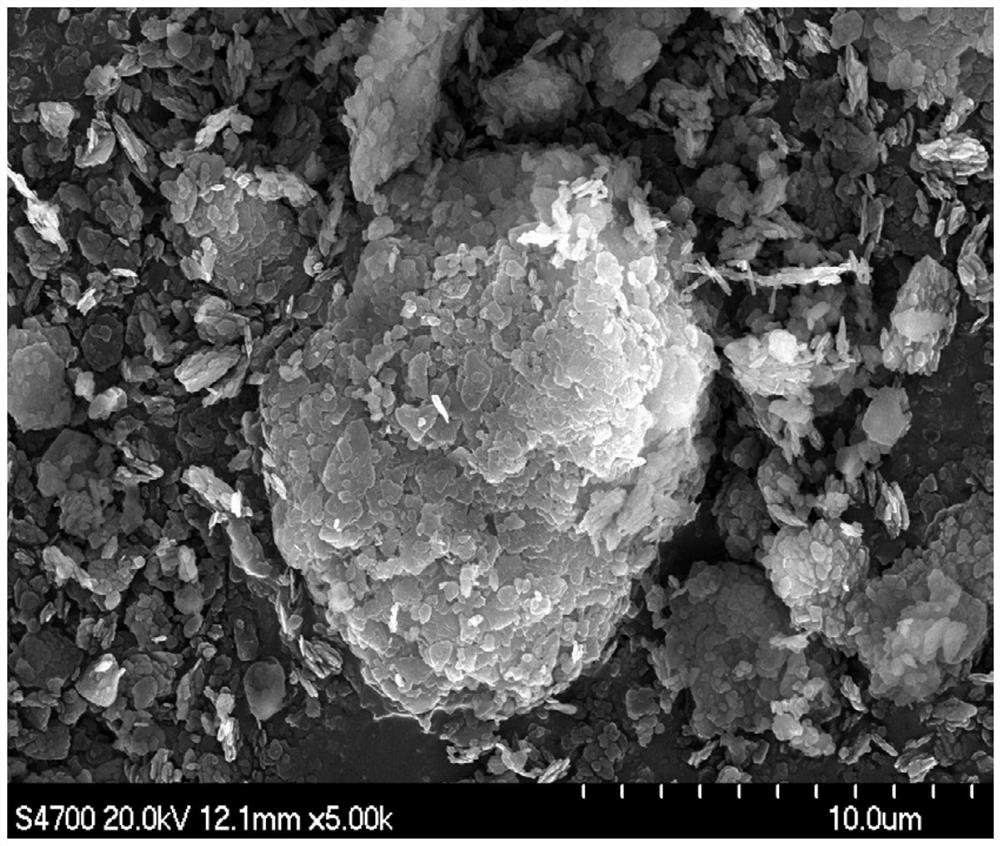

Image

Examples

Embodiment 1-1

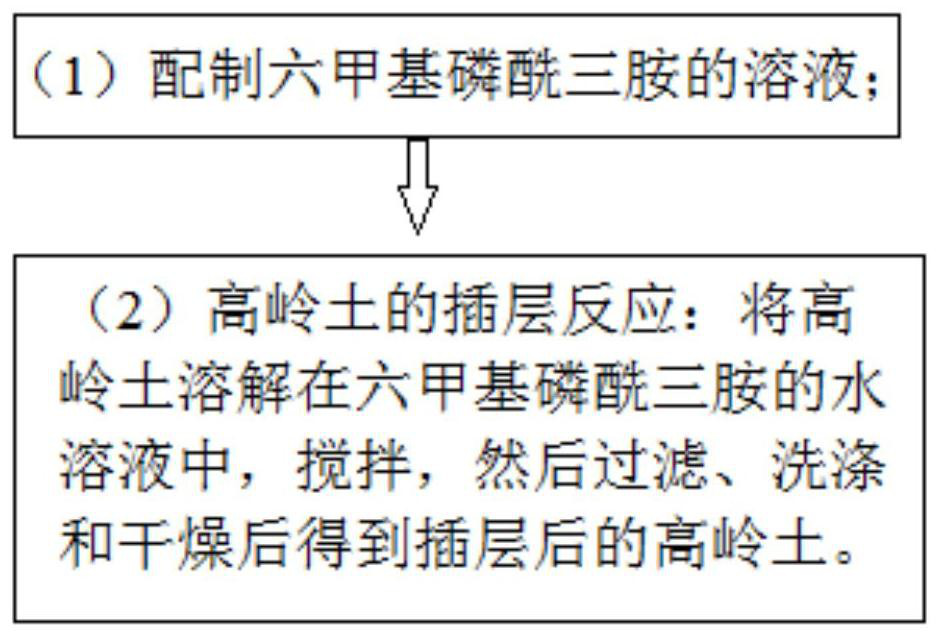

[0040] Preparation of hexamethylphosphoric triamide solution: use hexamethylphosphoric triamide as raw material, dilute it with deionized water, prepare an aqueous solution of hexamethylphosphoric triamide, and its mass fraction is 0.1-10% .

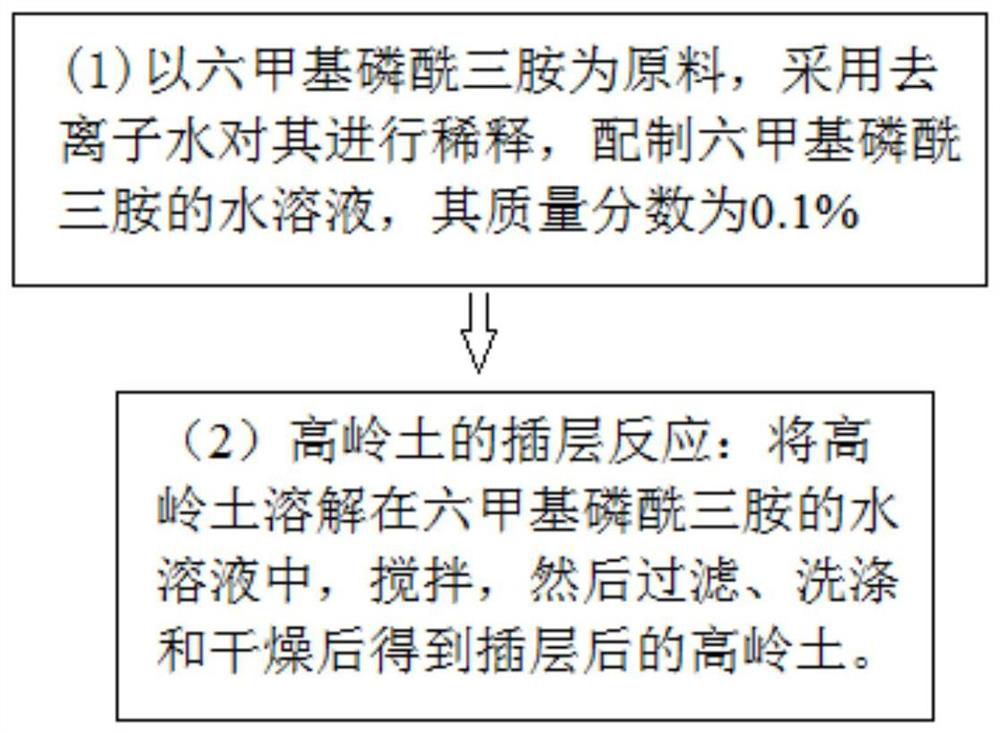

[0041] Hexamethylphosphoric triamide solution 1:

[0042] Using hexamethylphosphoric triamide as a raw material, dilute it with deionized water to prepare an aqueous solution of hexamethylphosphoric triamide, the mass fraction of which is 0.1%.

[0043] Hexamethylphosphoric triamide solution 2:

[0044] Using hexamethylphosphoric triamide as a raw material, dilute it with deionized water to prepare an aqueous solution of hexamethylphosphoric triamide, the mass fraction of which is 0.5%.

[0045] Hexamethylphosphoric triamide solution 3:

[0046] Using hexamethylphosphoric triamide as a raw material, dilute it with deionized water to prepare an aqueous solution of hexamethylphosphoric triamide, the mass fraction of which is 1%.

[004...

Embodiment 1

[0054] (1) Hexamethylphosphoric triamide solution 1.

[0055] (2) Dissolve kaolin in an aqueous solution of hexamethylphosphoric triamide, the mass ratio of the two is 1:2, and stir for 2 hours at 20°C. After filtering, washing and drying, intercalated kaolin J-1 was obtained.

Embodiment 2

[0057] (1) Hexamethylphosphoric triamide solution 2.

[0058] (2) Dissolve kaolin in an aqueous solution of hexamethylphosphoric triamide, the mass ratio of the two is 1:5, and stir for 4 hours at 30°C. After filtering, washing and drying, intercalated kaolin J-2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com