Hydro-thermal synthesis method for nano LiFePo4

A lithium iron phosphate, hydrothermal synthesis technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as shortening crystal nucleation and growth time, and achieve good batch stability, electrical conductivity and rate. The effect of improved performance and simplified control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, hydrothermal synthesis reaction

[0025] Will contain 223.4gFe 2+ (i.e. 4mol) pure ferrous sulfate solution diluted 3.5L (the pH value of this solution is about 1); Dilute 461.2g85% phosphoric acid containing pure phosphoric acid to 1L; 2 O was dissolved in water and diluted to 3L.

[0026] Add all the above-mentioned lithium hydroxide solution and phosphoric acid solution into a 10L autoclave with a sealed feeding tube and a heat exchange coil, after purging the air in the dead volume in the autoclave with an inert gas, seal the autoclave, start stirring, and the rotation speed is 200rpm, Heat from room temperature to 40°C, open the feed valve and exhaust valve, add all of the above-mentioned ferrous sulfate solution, feed for 30 minutes, close the feed valve to seal the autoclave after the feed is complete and continue to stir for 20 minutes.

[0027] Introduce 200°C steam into the reactor, so that the temperature in the reactor rises from 40°C to 16...

Embodiment 2

[0035] The time required for the reactants in Example 1 to be raised from the mixed temperature of 40° C. to 160° C. was changed to 15 minutes (the heating rate was 8° C. / min), and the others were the same as in Example 1.

[0036] After the synthesis is completed, filter, wash, and vacuum-dry the filter cake at 120°C to constant weight to obtain 624g LiFePO 4 Off-white powder.

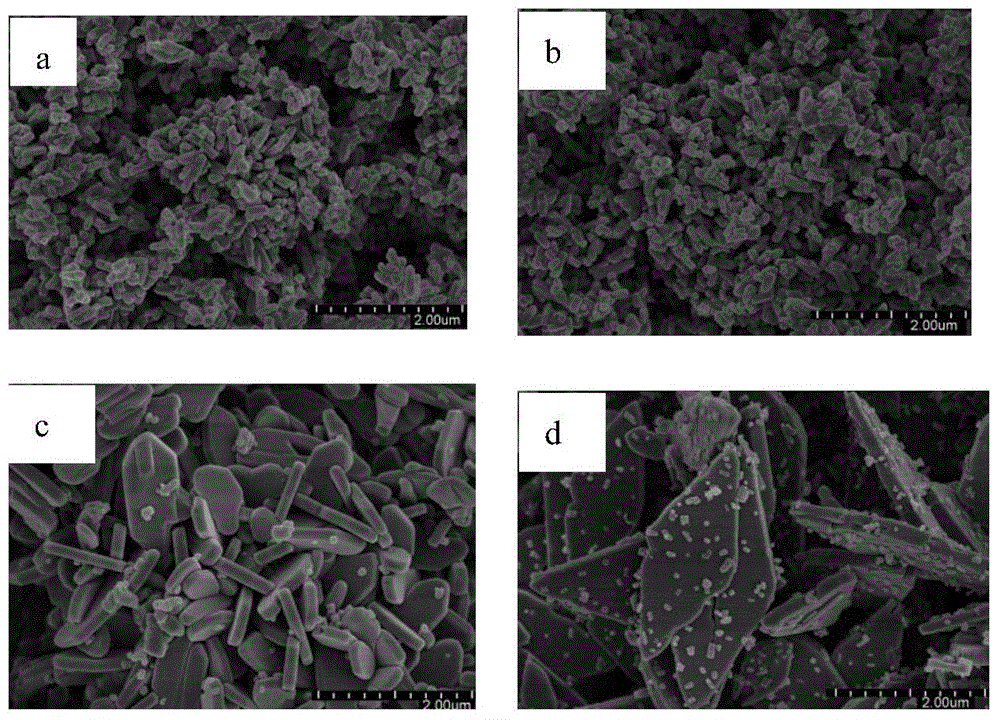

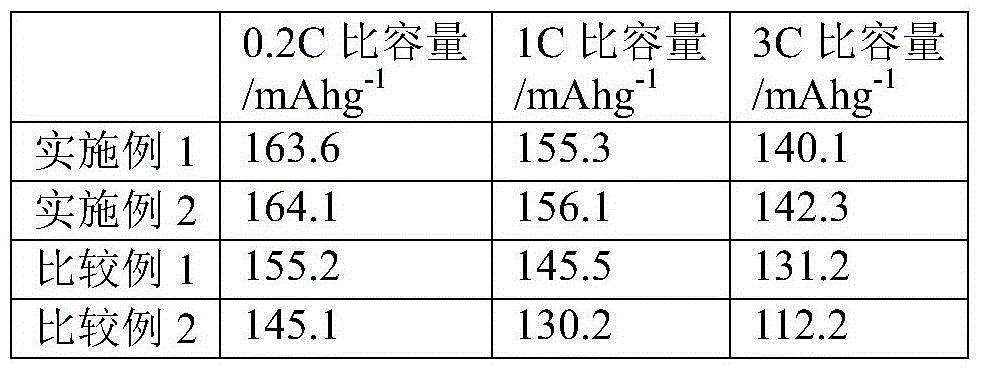

[0037] The particle morphology of the product is rod-shaped and spherical particles with unclear edges and corners, the minimum dimension of the particles is about 100 nanometers, and there is basically no agglomeration between the particles. The electrochemical performance test results are shown in Table 1. figure 1 b is a scanning electron micrograph of the sample obtained in this example. Compare figure 1 a and figure 1 b It can be seen that when the heating rate is greater than 4 °C / min, the morphology and particle size of the sample basically do not change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com