Resin and rubber combined binding agent grinding wheel for polishing of ceramic materials

A composite binder and resin rubber technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of short service life of polishing wheels, low polishing efficiency, and polishing quality that cannot meet the surface quality of precision ceramics. , to achieve the effect of high-speed polishing, good polishing performance and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

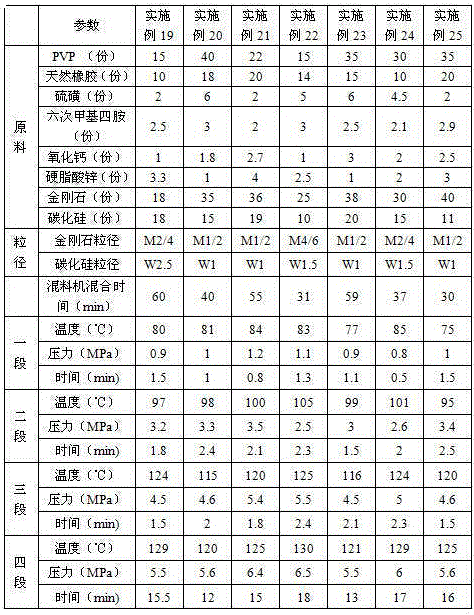

[0026] The resin-rubber composite binder grinding wheel for polishing ceramic materials of the present invention comprises a grinding wheel matrix 1 and an abrasive layer 2 bonded to the outside of the matrix; the matrix is a bakelite matrix; the abrasive layer is formed after mixing a composite binder and an abrasive; The binder is composed of polyvinyl butyral resin, natural rubber, vulcanizing agent, vulcanization accelerator and vulcanization activator; the abrasive is composed of diamond and silicon carbide; the volume ratio of each raw material in the abrasive layer is: polyvinyl alcohol 15-40 parts of butyral resin, 10-20 parts of natural rubber, 2-6 parts of vulcanizing agent, 3-6 parts of vulcanization accelerator, 1-4 parts of vulcanization activator, 18-40 parts of diamond powder, 10- 20 servings.

[0027] The bakelite substrate has certain strength and elasticity. On the one hand, it firmly carries the grinding wheel layer, and on the other hand, it is fixed with...

Embodiment 2

[0035] The resin-rubber composite binder grinding wheel for polishing ceramic materials of the present invention comprises a grinding wheel matrix 1 and an abrasive layer 2 bonded to the outside of the matrix; the matrix is a bakelite matrix; the abrasive layer is formed after mixing a composite binder and an abrasive; The binder is composed of polyvinyl butyral resin, natural rubber, vulcanizing agent, vulcanization accelerator and vulcanization activator; the abrasive is composed of diamond and silicon carbide; the volume ratio of each raw material in the abrasive layer is: polyvinyl alcohol 20 parts of butyral resin, 20 parts of natural rubber, 3 parts of sulfur, 4 parts of vulcanization accelerator, 3 parts of zinc stearate, 30 parts of diamond micropowder, 15 parts of silicon carbide micropowder, vulcanization accelerator including 2 parts of hexamethylene tetra amine and 2 parts calcium oxide.

[0036] The diamond powder type is PDM, the particle size is M1 / 2, the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com