A wear-resistant and tear-resistant flame-retardant cable

A flame-retardant cable, anti-tearing technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of toughness, impact resistance and other performance reduction, easy to tear, reduce the mechanical properties of cable materials, etc., and achieve good ozone resistance , enhance the tear resistance, increase the effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

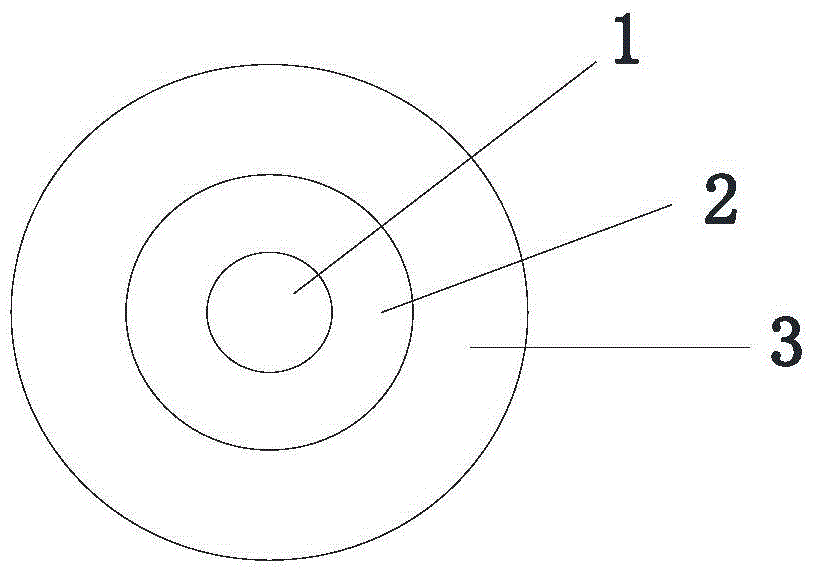

[0023] A wear-resistant and tear-resistant flame-retardant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0024] Wherein, the raw materials of the outer protective cover include by weight: 30 parts of thermoplastic polyurethane elastomer, 30 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 10 parts of hydrogenated nitrile rubber, 25 parts of dioctyl terephthalate, 15 parts of epoxy soybean oil, 25 parts of trioctyl trimellitate, 20 parts of nano-kaolin, 40 parts of nano-calcium carbonate, 30 parts of magnesium hydroxide modified by silane coupling agent, 20 parts of melamine cyanurate, peroxide 0.5 parts of dicumylbenzene, 3 parts of vulcanization accelerator TMTD, 1 part of magnesium oxide, 4 parts of Ca / Zn composite stabilizer, 2 parts of magnesium stearate, ...

Embodiment 2

[0026] A wear-resistant and tear-resistant flame-retardant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0027] Wherein, the raw materials of the outer protective cover include by weight: 50 parts of thermoplastic polyurethane elastomer, 50 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 20 parts of hydrogenated nitrile rubber, 15 parts of dioctyl terephthalate, 25 parts of epoxy soybean oil, 15 parts of trioctyl trimellitate, 40 parts of nano-kaolin, 20 parts of nano-calcium carbonate, 50 parts of magnesium hydroxide modified by silane coupling agent, 10 parts of melamine cyanurate, peroxide 3.5 parts of dicumyl, 1 part of vulcanization accelerator TMTD, 3 parts of magnesium oxide, 2 parts of Ca / Zn composite stabilizer, 3 parts of magnesium stearate, 0.1 par...

Embodiment 3

[0029] A wear-resistant and tear-resistant flame-retardant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0030] Wherein, the raw materials of the outer protective cover include by weight: 35 parts of thermoplastic polyurethane elastomers, 45 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, 12 parts of hydrogenated nitrile rubber, 22 parts of dioctyl terephthalate, 18 parts of epoxy soybean oil, 22 parts of trioctyl trimellitate, 25 parts of nano-kaolin, 35 parts of nano-calcium carbonate, 35 parts of magnesium hydroxide modified by silane coupling agent, 17 parts of melamine cyanurate, peroxide 1 part of dicumylbenzene, 2.5 parts of vulcanization accelerator TMTD, 1.5 parts of magnesium oxide, 3.5 parts of Ca / Zn composite stabilizer, 2.2 parts of magnesium st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com