Polypropylene mesh/electro-spinning nano-fiber membrane as well as preparation method and application thereof

A technology of polypropylene mesh and nanofiber membrane, applied in the field of medical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Polypropylene mesh was purchased from Bard Company, USA. That is, a non-absorbable material woven from polypropylene monofilaments, including a rectangular mesh sheet of about 6cm×4cm.

[0052] 2. Preparation of chitosan-polyethylene glycol hydrogel:

[0053] 1) Polyethylene glycol PEG (molecular weight 3000, 4000gmol -1 ) Dissolve in dichloromethane at 20-28°C in a nitrogen environment, the final concentration of PEG in the solution is 10% (g / 100ml);

[0054] 2) Dissolve 4-dimethylaminopyridine and triethylamine in dichloromethane to obtain mixed solution A, so that the concentration of 4-dimethylaminopyridine and triethylamine in mixed solution A are both 0.375mol / L, and then The mixed solution A is added to the PEG-containing dichloromethane solution prepared in the previous step and stirred for 15 minutes to obtain the mixed solution B. The volume ratio of the mixed solution A to the PEG-containing dichloromethane solution is 1:5;

[0055] 3) Add the mixed solution B d...

Embodiment 2

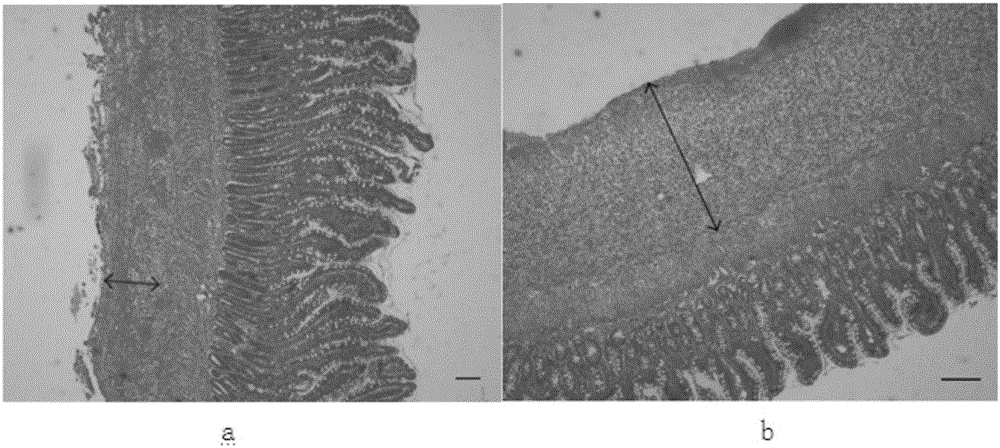

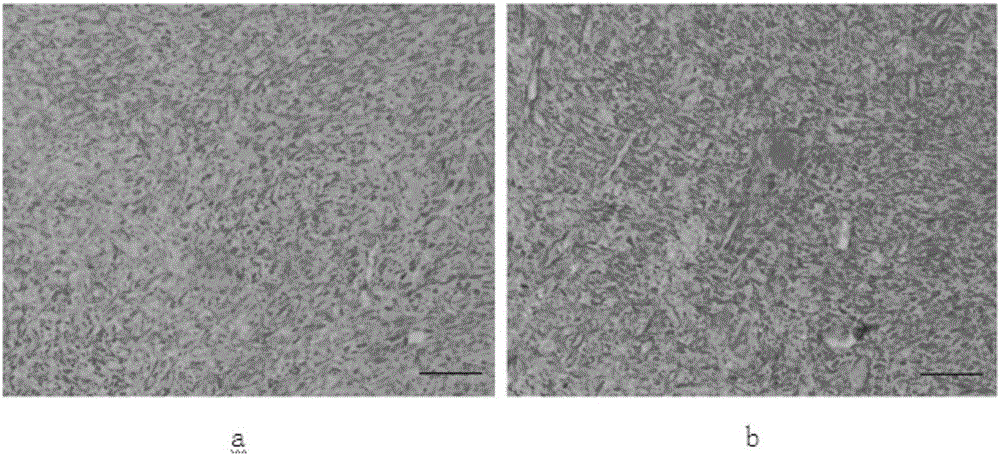

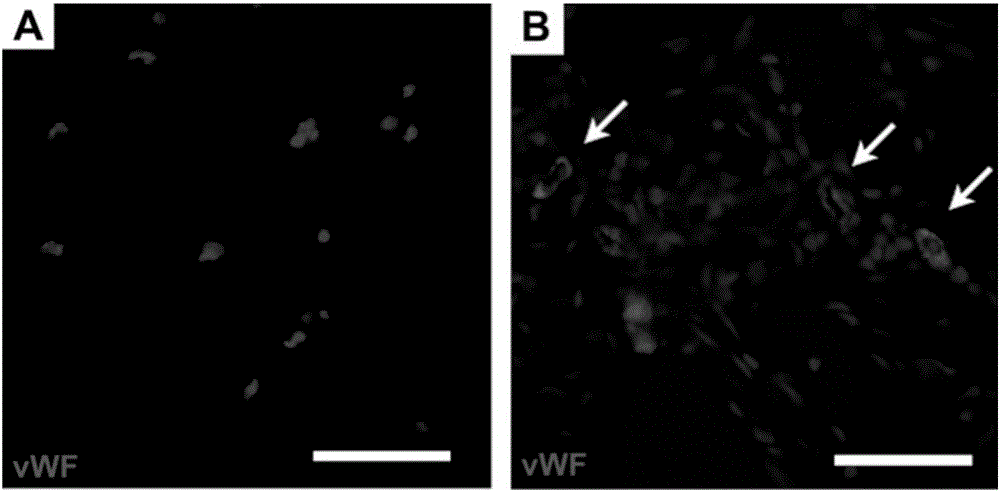

[0067] 1. Animals and grouping: 20 male SD rats (purchased from Shanghai Experimental Animal Center, Chinese Academy of Sciences), weight

[0068] 230~270g, randomly divided into 2 groups. Experimental group: The polypropylene mesh / nanofiber membrane prepared in Example 1 is cut into a polypropylene mesh / electrospun nanofiber membrane composite patch group (referred to as polypropylene mesh composite nanofiber membrane group) obtained by cutting into appropriate specifications. Control group: polypropylene mesh group.

[0069] 2. Surgical method: Animals are fasted for 8 hours before operation, and 1% ketamine 10ml / kg is injected intraperitoneally. After successful anesthesia, a model of abdominal wall defect caused by cecal ligation and perforation (CLP) combined with abdominal hypertension (IAH) was established. The details are as follows: take the midline incision of the abdomen, 20cm from the ileocecal area, cut off the small intestine circumference 1 / 3, away from the perforat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com