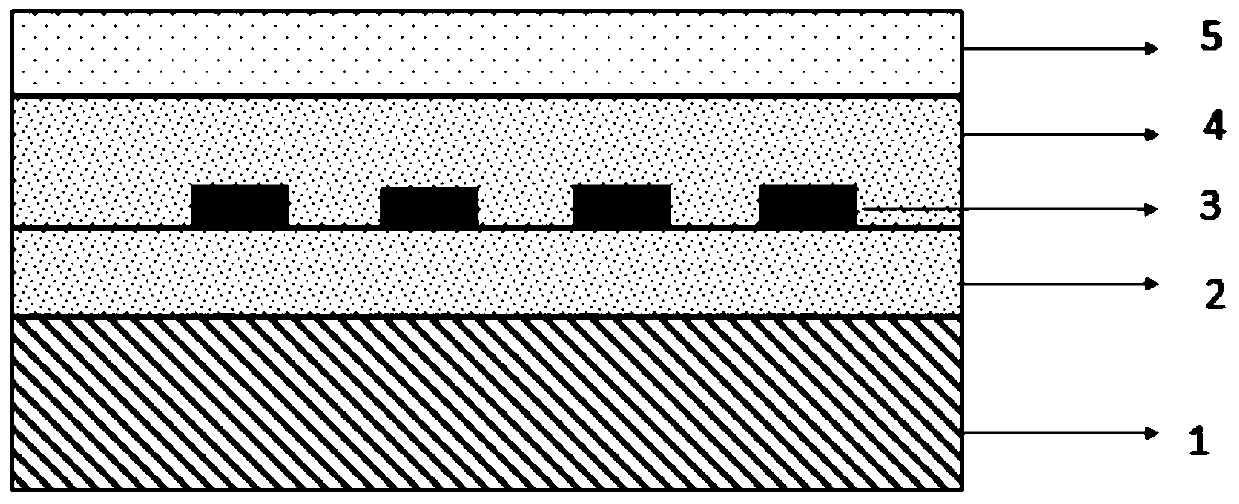

A kind of capacitive strain sensor and preparation method thereof

A sensor and capacitor technology, applied in the field of capacitive strain sensor and its preparation, can solve the problems of unfavorable control of the quality of dielectric materials, low strain and temperature, large dielectric loss, etc., and achieve accurate line width, high strain sensitivity, and low temperature. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

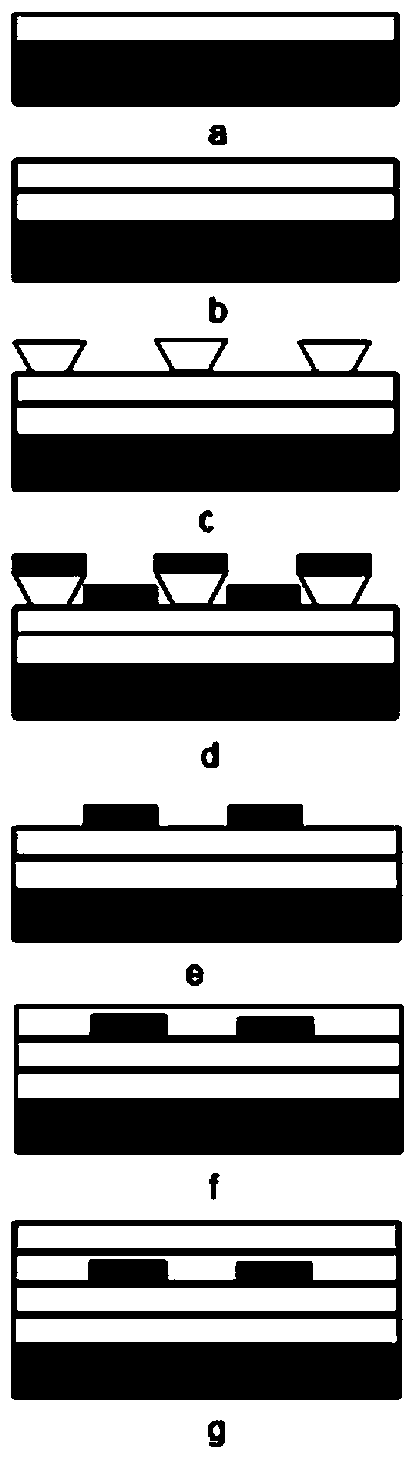

[0032] A preparation method of a capacitive strain sensor based on alumina ceramics, comprising the following steps

[0033] Step 1. Surface treatment of alumina substrate: use 1.25×1.25cm 99.9% alumina substrate as the substrate, successively use acetone, ethanol and deionized water to clean the substrate, and dry it with clean nitrogen after cleaning. ;

[0034] Step 2, depositing the first Ba on the alumina substrate 0.5 Sr 0.5 TiO 3 Dielectric film: put the alumina substrate cleaned in step 1 in a vacuum of 8.0×10 -4 Pa vacuum (back vacuum) environment, in Ba 0.5 Sr 0.5 TiO 3 Ceramic as the target material, argon gas with a purity of not less than 99.9% and 99.5% oxygen with a flow ratio of 4:1 as the reaction medium, at a temperature of 750°C, a power of 200W, and an air pressure of 2Pa, in alumina Deposit Ba with a thickness of 1 μm on the ceramic substrate 0.5 Sr 0.5 TiO 3 ceramic film;

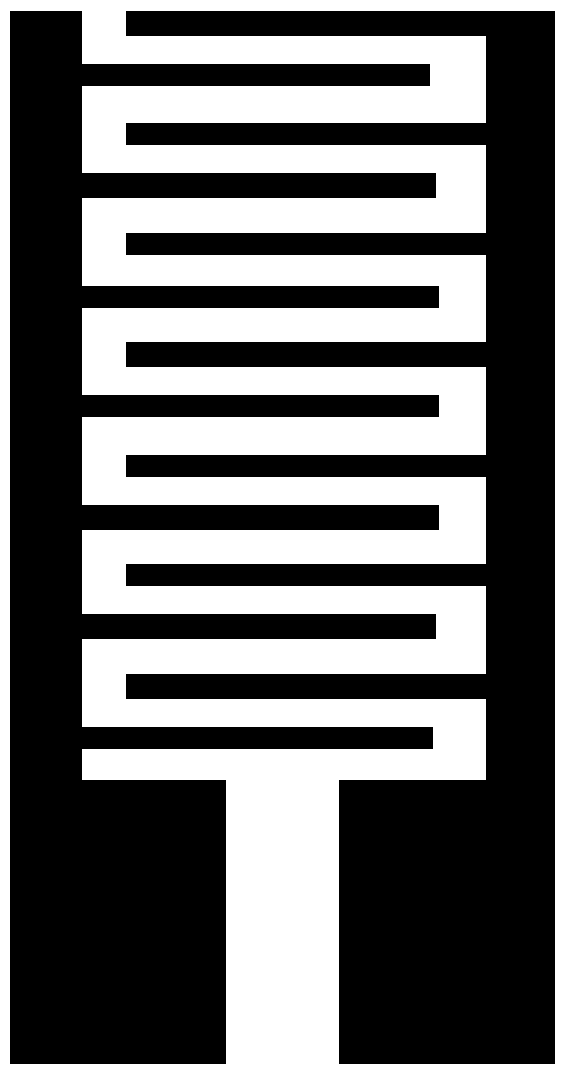

[0035] Step 3, preparation of patterned PdCr interdigital electrodes: p...

Embodiment 2

[0051] A method for preparing a capacitive strain sensor based on an alloy, comprising the following steps:

[0052] Step 1. Surface treatment of the substrate: first, polish the surface of the alloy substrate, and the polished surface is a mirror surface; then ultrasonically clean it in acetone, ethanol and deionized water for 10 minutes respectively, and dry it with clean nitrogen after cleaning;

[0053] Step 2. Prepare a NiCrAlY transition layer on the surface of the substrate cleaned in step 1: In order to improve the service life of the strain sensor in harsh environments and make the film have good adhesion, prepare a layer of transition layer NiCrAlY on the surface of the alloy substrate; The clean alloy substrate is placed in a vacuum of 8.0×10 -4 Pa vacuum (back vacuum) environment, with Ni 67 Cr 22 Al 10 Y alloy is used as the target material, and argon gas with a purity of 99.999% (volume percentage) is introduced as the sputtering medium. Under the conditions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com