A preparation method of amorphous nickel-phosphorus-tungsten carbide powder composite coating

A composite coating, amorphous nickel technology, applied in the field of preparation of amorphous nickel-phosphorus tungsten carbide powder composite coating, can solve problems such as no literature reports, achieve wide applicability, improve hardness and wear resistance, have The effect of contributing to corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

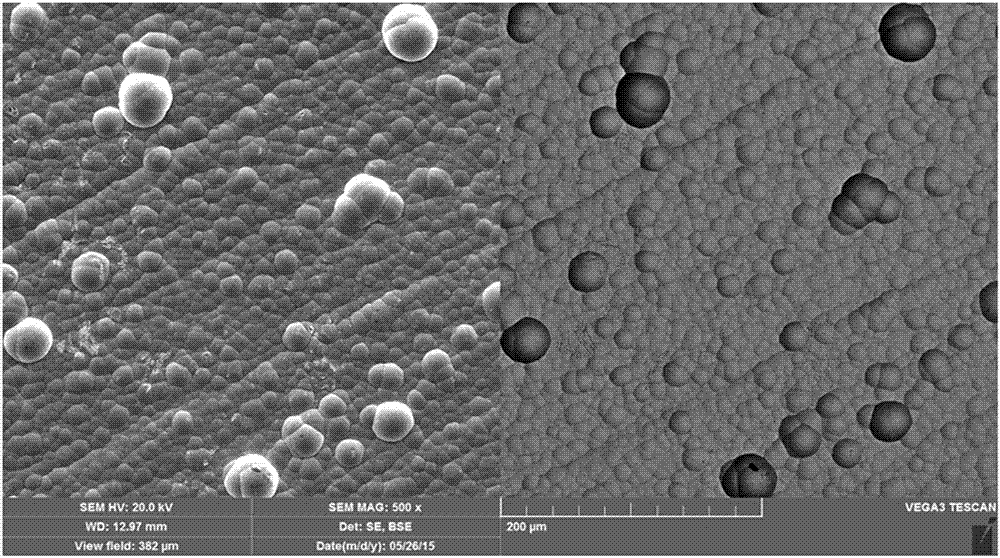

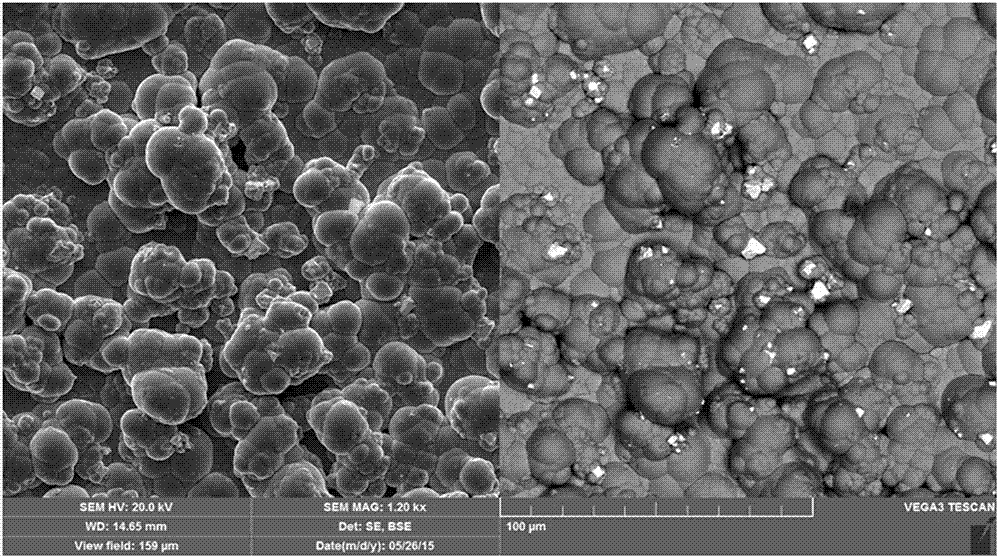

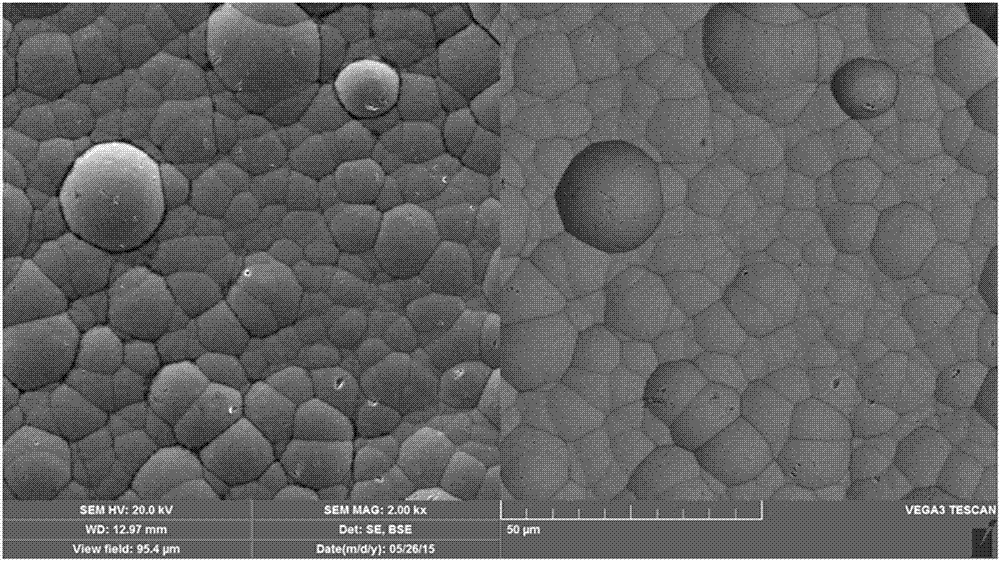

Image

Examples

Embodiment 1

[0050] (1) 45 steel sample, size

[0051] (2) Mechanically grind the 45 steel sample, and grind it step by step with 400, 600, 800, and 1000 mesh sandpaper to make the surface smooth and bright, then use deionized water to clean it ultrasonically, and then immerse the sample in acetone solution for ultrasonic cleaning Wash in the container for 5 minutes, remove grease, rinse with deionized water and dry; then put in sulfuric acid solution with a mass fraction of 15% to 20% for pickling and activation treatment for 3 minutes, and rinse with deionized water;

[0052] (3) Preparation of chemical plating solution and powder composite chemical plating solution

[0053]The chemical plating solution composition ratio is expressed in g / L as:

[0054] Nickel sulfate 25, sodium hypophosphite 30, sodium acetate 30, ammonium sulfate 30, lead acetate 1.

[0055] Plating solution configuration method:

[0056] (a) take by weighing required amount of nickel sulfate, sodium hypophosphite...

Embodiment 2

[0078] (1) Alloy steel 42CrMo sample, size 20mm×10mm×5mm

[0079] (2) The plating solution formula and steps (2) (3) (4) (5) (6) (7) of the present embodiment are exactly the same steps as in the above-mentioned embodiment 1. In the step (8), the voltage used in the pulse laser treatment is 600V, and the others are the same, and the surface hardness of the coating is 850HV, which is characterized by an amorphous coating by XRD analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com