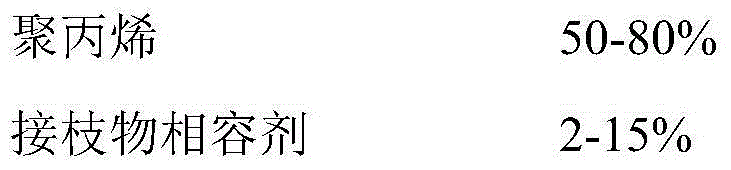

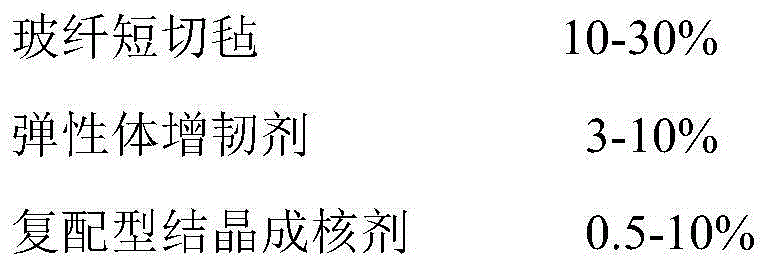

High-impact-resistance low-temperature-resistant glass-fiber-reinforced polypropylene composite material and preparation method thereof

A technology of composite material and polypropylene, which is applied in the field of high-impact and low-temperature-resistant glass fiber reinforced polypropylene composite materials and its preparation, can solve the problems of poor mechanical properties and low-temperature impact resistance, so as to improve impact resistance and structure Defects, the effect of increasing the cooling crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

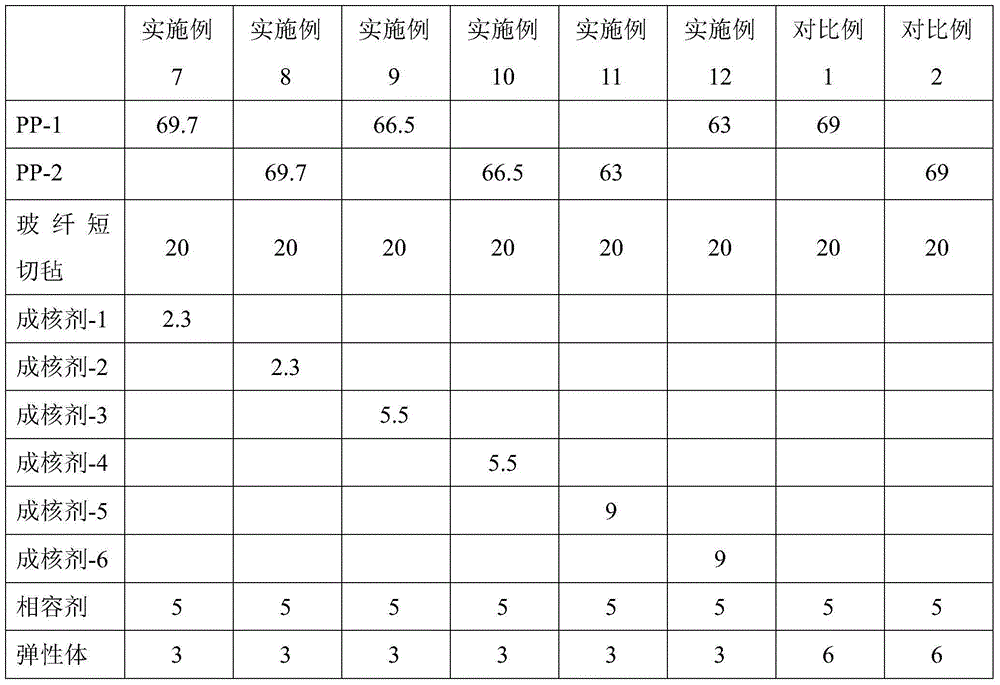

Embodiment 1

[0036] According to the data in Example 1 in Table 1, weigh β-type nucleating agent-1, β-type nucleating agent-2, whisker-1, and whisker-2, stir and mix evenly, and then the composite nucleating agent can be prepared Agent-1.

Embodiment 2

[0038] According to the data in Example 2 in Table 1, weigh β-type nucleating agent-1, β-type nucleating agent-2, whisker-1, and whisker-2, stir and mix evenly, and then a composite nucleating agent can be prepared Agent-2.

Embodiment 3

[0040] According to the data in Example 3 in Table 1, weigh β-type nucleating agent-1, β-type nucleating agent-2, whisker-1, and whisker-2, stir and mix evenly, and then a composite nucleating agent can be prepared Agent-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com