Internal inlet gas gas-cooling device of coagulation enhancing block of polycrystalline silicon ingot furnace and polycrystalline silicon ingot furnace

A technology of polycrystalline silicon ingot furnace and air cooling device, which is applied in the directions of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of reduced ingot solidification speed, long contact time, diffusion pollution, etc., and achieves improved cooling crystallization. speed, improve heat dissipation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

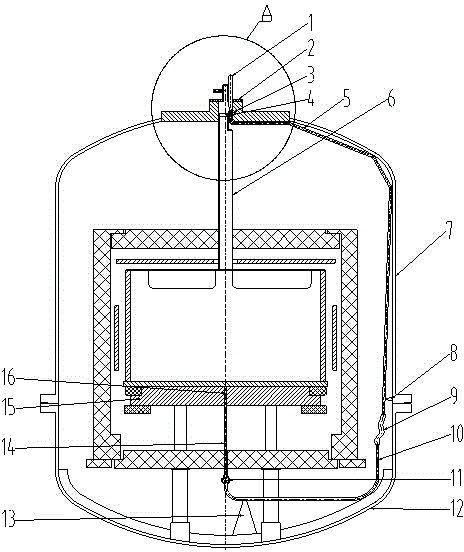

[0031] The present embodiment comprises roof cover 2, air inlet pipe cover 4, inner air inlet pipe I5, inner air inlet pipe II9, inner air inlet pipe III10, inner air inlet pipe IV14, clotting aid 15, and the inner air inlet pipe I5 inlet end passes through the air inlet pipe The small air intake hole 20 of lid 4; Inlet air intake pipe I5, interior air intake pipe II9, interior air intake pipe III10 and interior air intake pipe IV14 are connected successively, and interior air intake pipe IV14 stretches in the help clot 15 center hole 16 (as figure 1 shown).

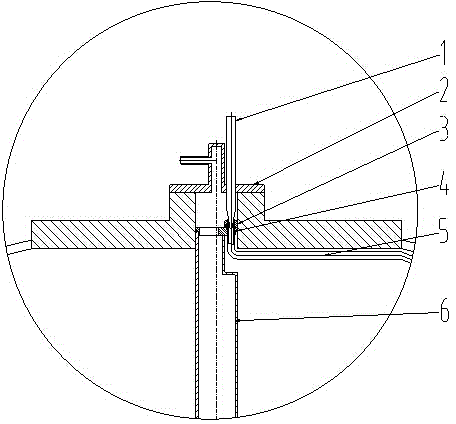

[0032] In order to control the on-off cooling gas, a conical rod 1 is arranged on the furnace roof 2, and the conical end of the conical rod 1 can extend into the air inlet of the inner air inlet pipe I5, and the diameter of the conical rod 1 is larger than that of the inner air inlet. The inner diameter of the intake pipe I5. Because the diameter of tapered rod 1 is greater than the inner diameter of inner air inlet pi...

Embodiment 2

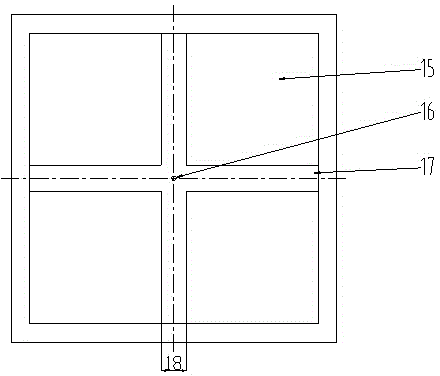

[0044] The difference between the present embodiment and embodiment 1 is only: the width 18 of the air guide groove 17 on the top of the clot 15 is 500mm, and the depth 19 is 0.5mm; the inner air intake pipe IV14 is a graphite tube; The diameter ratio of the hole 20 to the large air intake hole 21 is 0.8:1; the diameter of the large air intake hole 21 is 35 mm, and the diameter of the small air intake hole 20 is 28 mm; the cooling gas is an inert gas argon. The rest are the same as embodiment 1.

[0045] Taking GT ingot furnace G5 transformed into G6 as an example, the weight of the ingot is increased from 500 kg to 800 kg. If the crystal growth scheme of lifting the heat insulation cage is simply adopted, the crystal growth time will take about 40 hours, and the overall process The time is 75 hours; and after adopting the air inlet air cooling device in the polysilicon ingot furnace of the present invention to help clot, the crystal growth time is shortened to 30 hours, and t...

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is only: the nut 3 is a carbon-carbon composite material nut; the width 18 of the air guide groove 17 arranged on the top of the clot 15 is 250mm, and the depth 19 is 10mm; the inner air intake pipe IV14 is graphite Tube; the diameter ratio=0.6:1 of the small air intake hole 20 and the large air intake hole 21 of the intake pipe cover 4, the diameter of the large air intake hole 21 is 35mm, and the diameter of the small air intake hole 20 is 21mm; the cooling gas is inert Gas Argon.

[0048] Taking GT ingot furnace G5 transformed into G6 as an example, the weight of the ingot is increased from 500 kg to 800 kg. If the crystal growth scheme of lifting the heat insulation cage is simply adopted, the crystal growth time will take about 40 hours, and the overall process The time is 75 hours; and after adopting the air inlet air cooling device in the ingot casting furnace of the present invention to help the clot, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com