Metal nanowire-graphene bridge structure composite material and preparation method thereof

A technology of metal nanowire and bridge structure, applied in the direction of metal/alloy conductor, nanotechnology, nanotechnology, etc., to achieve the effect of improving conductivity, reducing contact resistance and reducing surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

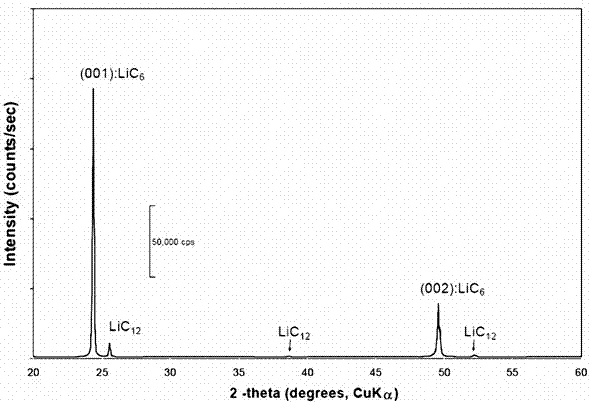

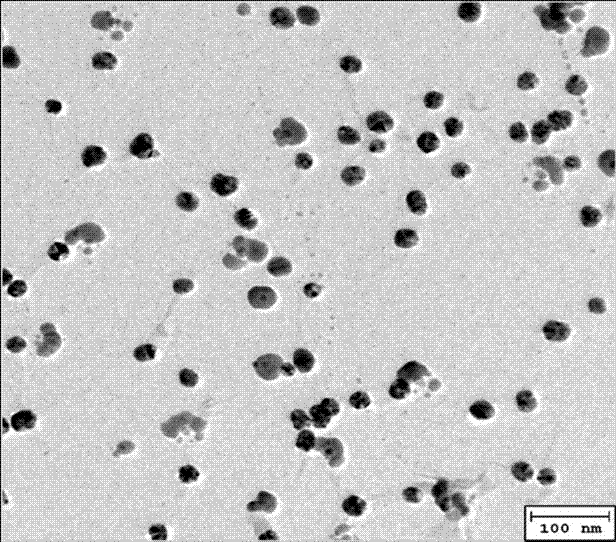

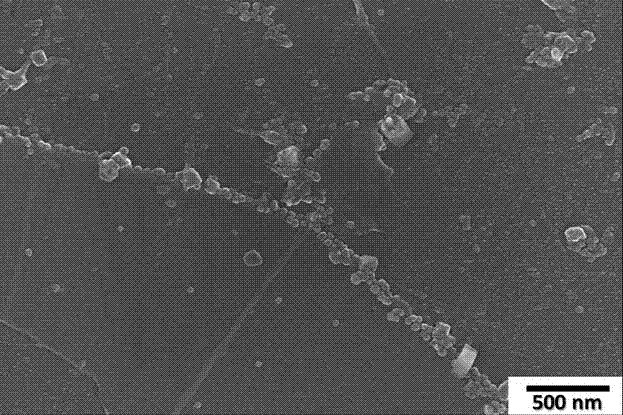

Image

Examples

preparation example Construction

[0074] 4.1 Preparation of silver nanowires

[0075] First, adding silver and solvents (such as silver nitrate and ethylene glycol) can make specific decisions about the reduction reaction and it will not swarm the solution phase reaction of Ag+ ions at high temperature 100 ~ 200 °C and grow selectively The directional growth of polymers (polyvinylpyrrolidone solution and additives (KBr in this case) are hindered and the concentration of Ag+ ions is fixed at a constant rate and the reduction rate of Ag+ ions in solution and it is stable at higher temperatures of 130~ 170°C.

[0076] The dissolution of the Ag precursor (AgNO3) and the nucleation step of the AgNW growth is followed by an appropriate step so that it injects the reaction constant major part of the reactant (AgNO3 in this case) and the Ag + ion to the polymer. It turns out that the specific crystal face formed by the sticks and silver nanowires is not what it is in the upper half. It maintains such a long enough s...

Embodiment 1

[0101] (1) Preparation of graphene oxide

[0102] 2g natural flake graphite (32) mesh, 2g NaNO3, 96ml concentrated H2SO4 were stirred and mixed at 0°C, and then 12g KMnO4 was slowly added to the mixture and kept stirring so that the heat could be dissipated well. The mixture was stirred at 0° C. for 90 minutes, then raised to 35° C. for 2 hours, and then 80 ml of deionized water was added dropwise to the mixture. After the dropwise addition, 10ml of hydrogen peroxide (30%) and 200ml of deionized water were added to the mixture in turn, and stirred for 10 minutes. After the reaction, graphite oxide was obtained. Graphite oxide was washed with deionized water to remove acid and water-soluble ions, and washed to neutral to obtain graphite oxide slurry, which was dispersed in water by weak ultrasound (80W, 10 minutes). Centrifuge the dispersion in the first step (3000 r / min, 5 minutes) to remove the lower layer of sediment (mainly unexfoliated graphite oxide and other impurities)...

Embodiment 2

[0114] Step 1: Preparation of Graphene Oxide

[0115] Partially oxidized graphite preparation: 1 gram of natural graphite flakes was first ground with sodium chloride crystals, washed with water to remove salt, and the graphite obtained by vacuum filtration and drying was soaked in 23 milliliters of concentrated sulfuric acid. The suspension was stirred for 12 hours, slowly adding 0.1 g of NaNO3 and 0.7 g of KMnO4, making sure that the latter was added very slowly to the vessel, and kept at 60°C for 1 hour. The solution was then stirred for 2 days, and 3 mL of deionized water was added. After 5 minutes, add another 3 ml of deionized water, and after 5 minutes, add another 40 ml of deionized water. After another 15 min, 140 mL of deionized water and 10 mL of 30% H2O2 were added. Then the suspension was centrifuged at 4500 rpm, washed repeatedly with deionized water, centrifuged, and finally dried at 80°C.

[0116] 0.5 g of myristyl ammonium was first dispersed in 20 ml of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com