Method for Determination of Elemental Components in Sulfur-Cobalt Concentrate and Sample Digestion Method

A technology for sulfide cobalt concentrate and element composition, applied in the field of detection and analysis, can solve the problems of increasing the concentration of solution salts, time-consuming, complicated operation, etc., and achieve the effect of avoiding excessive pressure increase and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

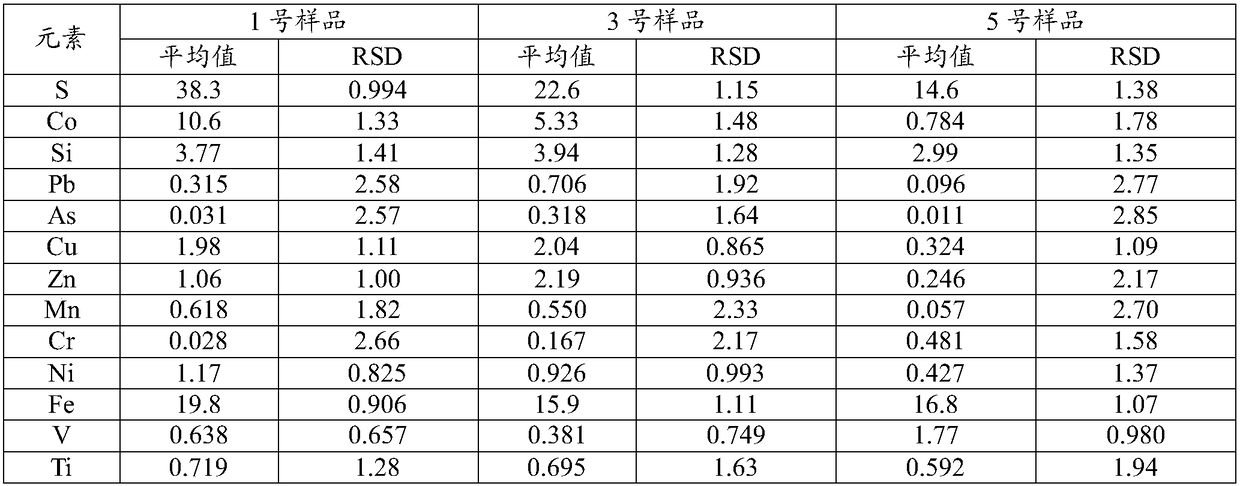

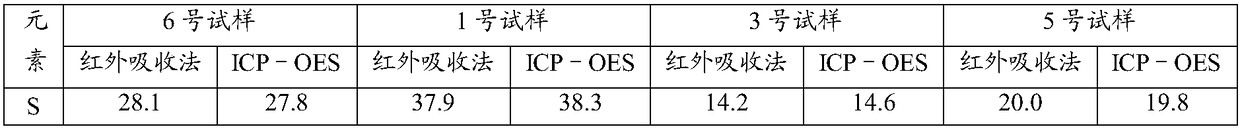

Embodiment 1

[0043] Digestion of sulfur cobalt concentrate samples

[0044] Weigh 0.2000g of sulfur-cobalt concentrate sample (hereinafter referred to as sample No. 1) into the inner tank of microwave digestion, add 10.0mL of water and 10.0mL of nitric acid along the wall of the container in sequence, then shake the container to evenly disperse the sample, and then add 2.0mL of hydrogen Hydrofluoric acid and 2.0mL hydrogen peroxide; put the outer tank on quickly, cover the lid and tighten it with a torque wrench to ensure a good seal, put the sealed digestion container into the microwave digestion furnace according to the instrument operation steps, connect the temperature and pressure Microwave digestion and complexation reactions were performed after the sensor. In this example, the microwave reaction method of ramping up the temperature is adopted, the pressure is controlled below 800 psi (1 psi = 6.895 KPa), and the digestion reaction is divided into three stages and the temperature i...

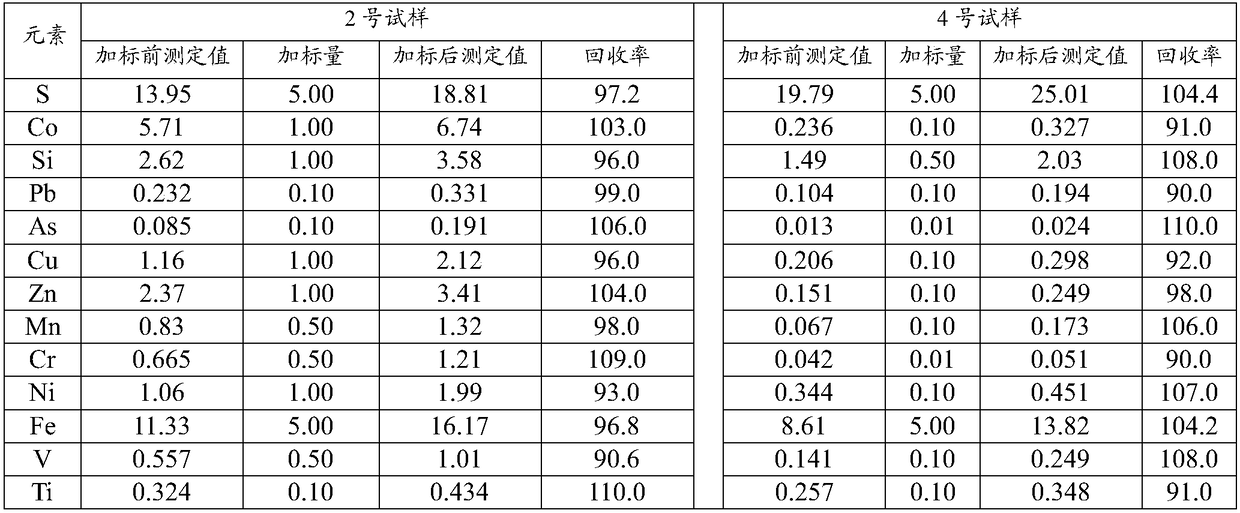

Embodiment 2

[0049] Weigh 0.5000g of sulfur-cobalt concentrate sample (hereinafter referred to as No. 2 sample), add successively the combined digestion reagent of 15.0mL water, 15.0mL nitric acid, 3.0mL hydrofluoric acid and 3.0mL hydrogen peroxide, then seal the container for Microwave digestion; the pressure is controlled below 800psi, and the microwave heating conditions are first to raise the temperature to 90°C for 5 minutes and keep it for 5 minutes for low-temperature digestion, then raise the temperature to 150°C for 10 minutes and keep it for 10 minutes for medium-temperature digestion, and finally raise the temperature to 200°C for 5 minutes and keep it for 7 minutes High-temperature enhanced digestion; after the microwave digestion solution is cooled to room temperature, it is directly diluted with water and fixed to volume in a 200mL plastic volumetric flask.

[0050] Besides, the sulfur-cobalt concentrate sample was digested in the same way as in Example 1, and the solution wa...

Embodiment 3

[0052] Weigh 0.3000g of sulfur-cobalt concentrate sample (hereinafter referred to as No. 3 sample), add successively the combined digestion reagent of 10.0mL water, 10.0mL nitric acid, 2.0mL hydrofluoric acid and 2.0mL hydrogen peroxide, then seal the container for Microwave digestion; the pressure is controlled below 800psi, and the microwave heating conditions are first to raise the temperature to 80°C for 4 minutes and keep it for 4 minutes for low-temperature digestion, then raise the temperature to 140°C for 7 minutes and keep it for 8 minutes for medium-temperature digestion, and finally raise the temperature to 190°C for 5 minutes and keep it for 6 minutes High-temperature enhanced digestion; after the microwave digestion solution is cooled to room temperature, it is directly diluted with water and fixed to volume in a 100mL plastic volumetric flask.

[0053] Besides, the sulfur-cobalt concentrate sample was digested in the same way as in Example 1, and the solution was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com