Method for extracting isobavachalcone from fresh angelica keiskei

A new and fresh technology of isopsoralenchalcone, which is applied in the field of preparation of isopsoralenchalcone, can solve the problems that the preparation method has not been reported, and achieve the goal of reducing the difficulty of process control, saving energy, and having a single component Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

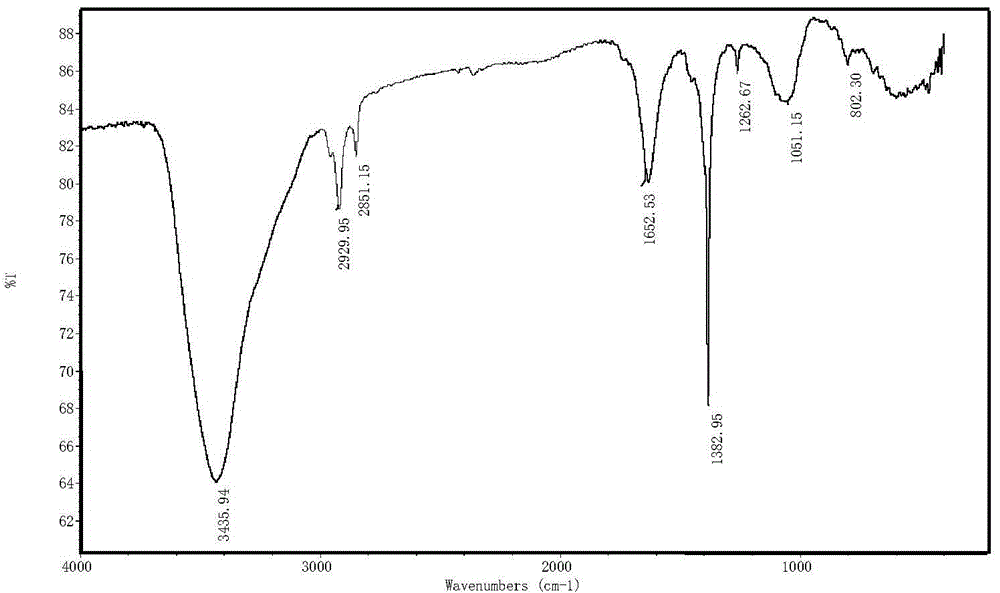

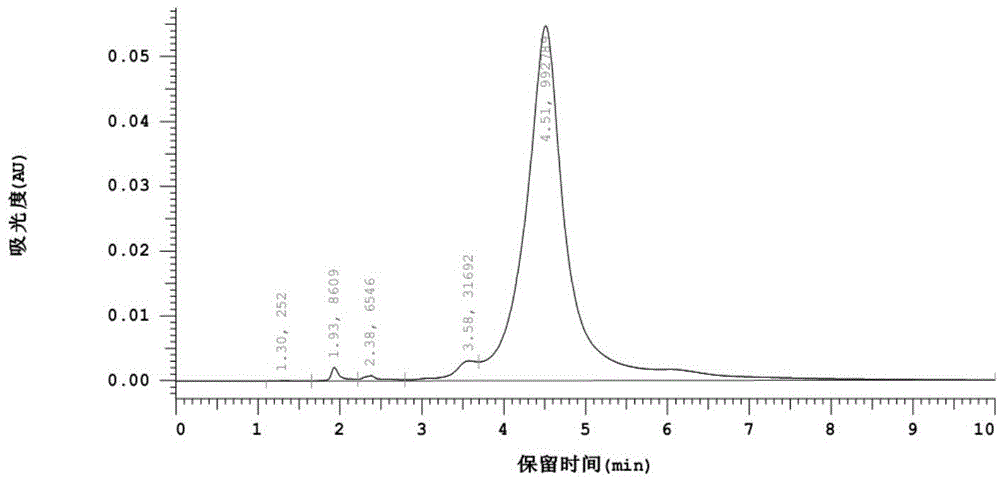

Image

Examples

Embodiment 1

[0048] (1) Beat 1Kg fresh sun leaves, mix according to the ratio of the volume ratio of the slurry to the alcohol-water solution of 1:7, wherein the volume ratio of ethanol to water is 19:2, heat up to 72°C, stir and leaching for 3 hours, then filter , Obtain 7.5L filtrate A.

[0049] (2) Mix A and n-hexane at a ratio of 1:1 by volume, stir for 3 hours, remove chlorophyll impurities, let stand to separate, and take 7L of hydroalcoholic phase B.

[0050] (3) Mix B and saturated lime water at a volume ratio of 1:0.3 for 2 hours to remove tannin and other alkali-soluble impurities, and filter to obtain 8.5L of filtrate C.

[0051] (4) Mix C and ethyl acetate at a volume ratio of 1:0.5, then add 1.5 L of 10% sodium bicarbonate and shake for 4 hours to remove fat-soluble impurities to obtain 9.6 L of aqueous phase D.

[0052] (5) Replace the macroporous resin AB8 separation column on D for 1.5 hours, wash with water to remove small water-soluble molecules such as sugars, and final...

Embodiment 2

[0055] (1) Beat 1Kg fresh sun leaves, mix according to the volume ratio of slurry and alcohol-water solution is 1:7, wherein, the volume ratio of methanol to water is 17:2, heat up to 72°C, stir and leach for 3h, then filter , to obtain 7L filtrate A.

[0056] (2) Mix A and chloroform at a ratio of 1:0.5 by volume, stir for 3 hours, remove chlorophyll impurities, let stand to separate, and take 7L of hydroalcoholic phase B.

[0057] (3) Mix B and saturated lime water at a ratio of 1:0.1 by volume and react for 1 hour to remove tannins and other alkali-soluble impurities, and filter to obtain 8L of filtrate C.

[0058] (4) Mix C and dimethyl carbonate at a volume ratio of 1:0.3, then add 1.5 L of 10% sodium hydroxide and shake for 4 hours to remove fat-soluble impurities to obtain 9.1 L of aqueous phase D.

[0059] (5) Replace the macroporous resin D101 separation column on D for 1.5h, wash with water to remove small water-soluble molecules such as sugars, and finally elute wi...

Embodiment 3

[0062] (1) Beat 1Kg fresh sun leaves, mix according to the volume ratio of slurry to alcohol-water solution is 1:7, wherein the volume ratio of n-butanol to water is 21:2, heat up to 72°C and stir and leach for 3h After filtration, 8.2L of filtrate A was obtained.

[0063] (2) Mix A and acetone at a ratio of 1:2 by volume, stir for 3 hours, remove chlorophyll impurities, let stand to separate, and take 7.7L of hydroalcoholic phase B.

[0064] (3) Mix B and saturated lime water at a volume ratio of 1:0.5 for 3 hours to remove tannin and other alkali-soluble impurities, and filter to obtain 8.7L of filtrate C.

[0065] (4) Mix C and ethyl formate at a volume ratio of 1:1, then add 1.5 L of 10% ammonia water and shake for 4 hours to remove fat-soluble impurities, and obtain 9.1 L of aqueous phase D.

[0066] (5) Replace the macroporous resin D140 separation column on D for 1.5 hours, wash with water to remove small water-soluble molecules such as sugars, and finally elute with 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com