Adhesive-free cutting method for silicon dioxide evaporation material

A technology of silicon dioxide and cutting methods, applied in stone processing equipment, fine working devices, working accessories, etc., can solve problems such as complicated processes, waste, and exhaust gas pollution, and achieve energy saving and labor saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

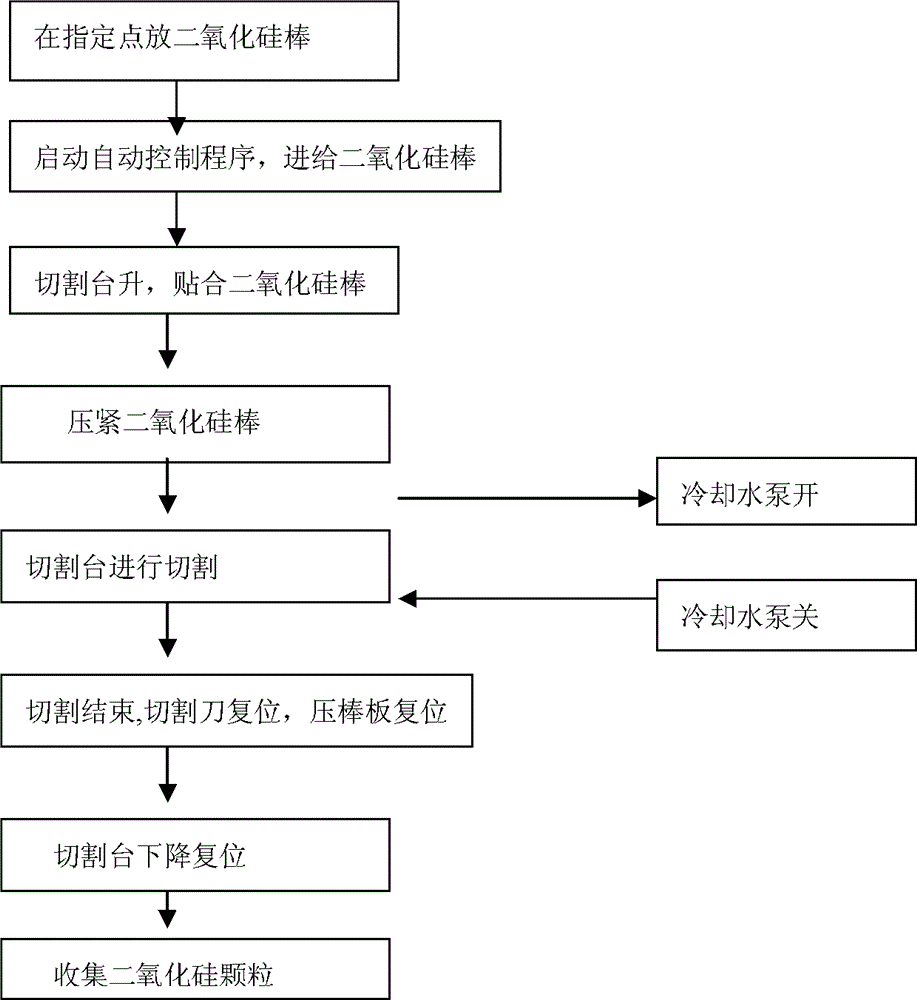

[0019] Embodiment: be that 60 silica rods of 2mm carry out glue-free cutting with diameter as example, concrete steps are as follows:

[0020] Step 1: Manually spread 60 silica rods with a diameter of 2mm on the designated position of the guide platform without any chemical adhesive;

[0021] Step 2: Start the digital programmable controller (PLC) automatic program, and the rubber roller clamp rod is fed into a cutting width;

[0022] Step 3: The cutting platform rises and fits the silica rod;

[0023] Step 4: Under the pressure of the cylinder, the rod pressing plate is extended to the position close to the silica rod, and the strong magnet of the magnetic suction device under the cutting table and the pressing rod plate are attracted by each other to form a force to press the bar;

[0024] Step 5: The cutting blade moves horizontally to the silica rod at a speed of 2800rpm along the direction vertical to the axis of the silica rod to cut, and at the same time the cooling wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com